- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jul . 25, 2025 04:01 Back to list

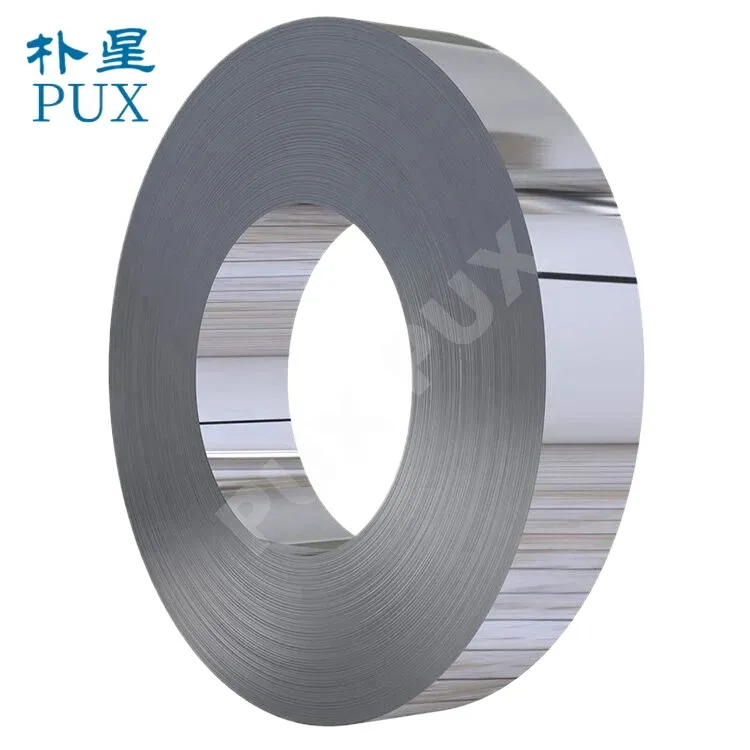

High Quality Precision Stainless Steel Strip for Industrial Use

As global manufacturing standards continue to advance, the demand for high quality precision stainless steel strip rises rapidly, driven by industries requiring reliable, corrosion-resistant, and dimensionally accurate materials. Whether for electronics, automotive, medical devices, or construction, the move toward miniaturization and high-tech fabrication elevates the necessity for top-grade cold rolled stainless steel strip, stainless steel strip coil, and stainless steel strip roll products.

This detailed guide takes you from understanding the high quality precision stainless steel strip sector's latest trends, technological parameters, and application fields through to a comprehensive evaluation of product advantages and industry-specific data analysis.

Proudly presented by Hebei Pux Alloy Technology Co., Ltd (Official Website), an industry-leading supplier with more than a decade’s experience in producing excellence.

Industry Trends and the Evolving Market

The global high quality precision stainless steel strip market is forecasted to grow at a CAGR exceeding 6% between 2024 and 2030 (Grand View Research). This trend is accentuated by technological innovation, the transition toward eco-friendly stainless alloys, and growing requirements for micro-tolerance materials across automotive, consumer electronics, and new energy sectors.

- Miniaturization: The adoption of thinner strips (as low as 0.1mm) enables electronics and sensor fabrication.

- Surface Quality: Mirror and matte finishes are increasingly popular for decorative and architectural needs.

- Automated Processing: Automation in slitting, rolling, and packaging ensures defect-free supply and competitive lead times.

- Material Innovations: Alloys like 304, 316L, and high-nickel series enhance corrosion resistance and machinability.

Key related product types include cold rolled stainless steel strip, stainless steel strip coil, and stainless steel strip roll, each serving distinct applications and tailored surface requirements.

About Hebei Pux Alloy Technology Co., Ltd

Website: https://www.puxingclamp.com

Phone: +86-0319-8862898

Email: inquiry@puxingclamp.com

Mobile: +86-17331948172

Address: East Zhaozhuang Village, Shahe Town, Xingtai City, Hebei Province, China

Hebei Pux Alloy Technology Co., Ltd specializes in the research, development, and manufacturing of stainless steel strips using advanced rolling and slitting technologies. Our production is founded on strict quality standards and authoritative certifications such as ISO 9001, ensuring excellence and product traceability across global markets.

Product Information & Technical Profile: High Quality Precision Stainless Steel Strip

The featured Cold Rolled Stainless Steel Strip (Product Details) stands at the forefront of the market due to its superior mechanical, surface, and dimensional qualities:

- Base Material: Hot rolled stainless steel blank

- Process: Cold rolling (room temperature) using precision mills

- Thickness: 0.1-3mm; Width: 100-2000mm

- Surface Finish: Bright, matte, mirror, or custom as per application

- Mechanical Properties: High strength, superior ductility, enhanced corrosion resistance

- Dimensional Tolerance: Typically ±0.01mm or better

- Delivery Format: Most often supplied as coil or roll

- Further Processing: Slitting, punching, coating, and shaping into finished products

Compared to hot rolled variants, cold rolled strips boast higher dimensional precision, a low surface roughness, and outstanding flatness, making them the material of choice for further processing into coated and decorative steel plates.

Technical Parameter Table: High Quality Precision Stainless Steel Strip

| Parameter | Typical Range | Industry Standard | Importance |

|---|---|---|---|

| Thickness | 0.1mm – 3mm | ASTM A240, EN 10258 | Enables precision fabrication, key for electronics/automotive |

| Width | 100mm – 2000mm | JIS G4305 | Supports custom rolls and wide strip coil needs |

| Surface Finish | 2B, BA, No.4, Mirror | GB/T 3280 | Impacts corrosion resistance & aesthetics |

| Tensile Strength | 520-750 MPa | ASTM E8/E8M | Critical for structural parts, springs |

| Yield Strength | 200-350 MPa | ASTM A240 | Indicates load handling ability |

| Elongation (%) | 30-55% | EN 10088 | Higher elongation, better formability |

| Hardness | HV 160-210 | HV Scale | Defines wear resistance |

| Corrosion Resistance | Excellent | ASTM A262 | Essential for harsh environments |

Technical Parameter Trends

Application Fields of High Quality Precision Stainless Steel Strip

- Automotive & EV: Battery cases, connectors, fuel system components

- Electronics: Mobile phone shields, flexible circuits, EMI gaskets

- Medical Devices: Surgical tools, implantable devices, diagnostic instruments

- Construction: Decorative trims, expansion joints, elevator panels

- Energy Sector: Solar clips, battery shell, precision springs

- Food & Household: Appliances, kitchen utensils, sterile surfaces

Cold Rolled Stainless Steel Strip – Key Technical Index Comparison

Cold Rolled vs Hot Rolled Stainless Steel Strip – Key Performance Index

Main Grades Share of Cold Rolled Stainless Steel Strip Production

Thickness Range Distribution – Cold Rolled Stainless Steel Strip

Frequently Asked Professional Questions (FAQ)

1. What are the main material grades used in high quality precision stainless steel strip?

2. What thickness and width tolerances can be achieved?

3. What surface finishes are available for cold rolled stainless steel strip?

4. How does stainless steel strip coil packaging meet export standards?

5. Are products certified for hygiene or specific industry compliance?

6. Which installation standards apply for stainless steel strip roll in construction?

7. How does cold rolling improve mechanical properties over hot rolling?

Why Choose Hebei Pux Alloy Technology Co., Ltd for High Quality Precision Stainless Steel Strip?

- Advanced rolling, slitting, and edge-trimming equipment

- Strict QC and traceability—backed by international certifications

- Fast lead times, Made-to-Order material grades & custom packaging

- Global export expertise, serving 38+ countries

- Responsive after-sales and technical support – direct hotline, email, and WeChat/WhatsApp

For tailor-made solutions or consultation, contact us:

Tel: +86-0319-8862898 | Email: inquiry@puxingclamp.com

References & Authority Citations

- Grand View Research, Stainless Steel Market Analysis.

- World Stainless Association, Official Portal.

- Journal of Materials Processing Technology: Research on High-Precision Stainless Steel Strip Manufacture

- Steelonthenet Stainless Industry News & Forum

- ResearchGate: High Precision Cold Rolled Technologies & Trends

-

Heavy Duty Hose Clamp – Durable Stainless Steel Automotive Tube Clip

NewsJul.26,2025

-

High Quality Precision Stainless Steel Strip for Industrial Use

NewsJul.25,2025

-

Black Rubber Hose Clamp with Rubber Lined & Insulated Design for Secure Fitting

NewsJul.24,2025

-

High Quality Steel Stainless Midsole for Safety Shoes Supplier

NewsJul.23,2025

-

High Quality Hose Clamps Mini Clips - German Style & Stainless Steel

NewsJul.22,2025

-

High Quality Steel Midsoles in EN Standard | Safety Footwear

NewsJul.22,2025