products

As a leader in the field of stainless steel deep processing, Hebei Yaxin Stainless Steel Products Co., Ltd. has leveraged nearly two decades of technical expertise to develop a premium series of high-precision stainless steel strips with thickness accuracy up to 0.08mm and hardness reaching HRC600. Our ultra-thin, high-hardness stainless steel strips employ unique cold-rolling processes and precision heat treatment technology, delivering exceptional formability alongside military-grade mechanical properties. This breakthrough effectively addresses industry challenges such as deformation and wear in extreme operating conditions.

From the sharp edges of kitchen knives to the durable cycles of automotive springs, from the dimensional stability of precision measuring tools to the tensile protection of armored cables, Yaxin stainless steel strips are redefining the performance limits of 300 and 400 series stainless steel.

-

Cold Rolled 201/304/202/316 Grade Stainless Steel Coil/Strip/Sheet

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mm

Surface Technics:2B/BA/polished/fogging surface

Quality Standard:Certificate of conformity

Packaging:Packing shall depend on the customer's requirements

Applications:Stainless steel strip produced by Hebei Yaxin Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes,hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro- parts etc.

-

Thickness 0.1-2mm 201/304/202/316 Grade Stainless Steel strips Cold Rolled Steel coils

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mm

Width:4-690mm

Surface Sechnics:2B/BA/polished/fogging surface

Quality Standard:Certificate of conformity

Packaging:Packing shall depend on the customer'srequirements

Applications:Stainless steel strip produced by Hebei Yaxin

Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes,hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro-parts etc.

-

Factory Direct sell SS201/SS304/SS202/SS316 stainless Steel Strip

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mmWidth:4-690mm

Surface technics:2B/BA/polished/fogging surface

Quality standard:Certificate of conformity

Packaging:Packing shall depend on the customer'srequirements

Applications:Stainless steel strip produced by Hebei Yaxin Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes, hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro-parts etc.

-

China Stainless Steel Coil Factory Export Stainless Steel Strip /belt/coils/plate

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mm

Width:4-690mm

Surface Technics:2B/BA/polished/fogging surface

Quality Standard:Certificate of conformity

Packaging:Packing shall depend on the customer'srequirements

Applications:Stainless steel strip produced by Hebei Yaxin

Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes,hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro-parts etc.

-

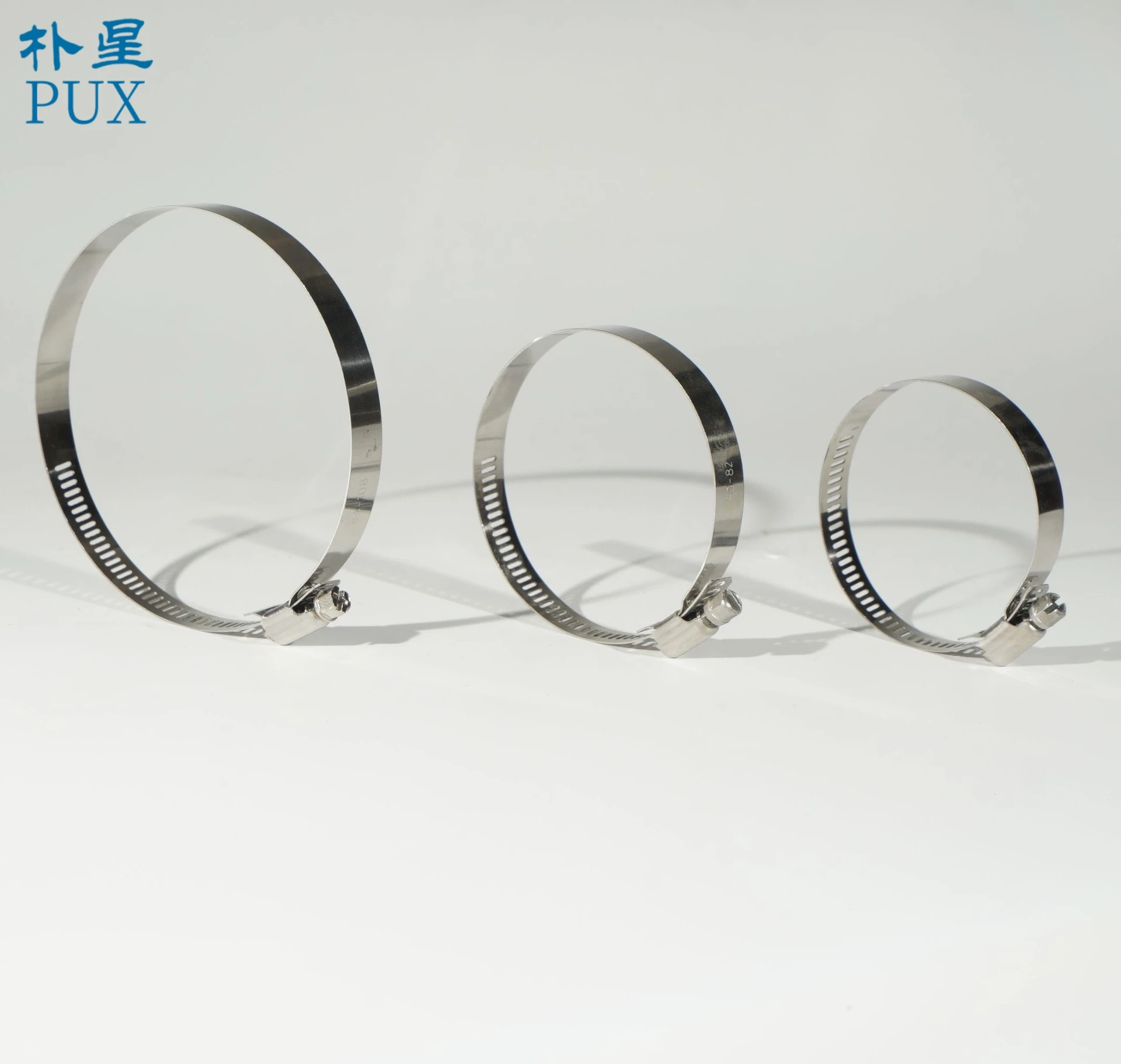

Stainless steel 304 hose clamps

Lightning Customization, Fast Sampling

Elevate Your Space with Stainless Steel 304: Timeless Elegance, Unmatched Reliability

stainless steel 304 hose clamps offer a combination of durability, reliability, and resistance to environmental factors that make them a popular choice for various industries and applications.

Item:mini American hose clamp

Thickness: 0.6mm

Bandwidth: 8mm

Brand:PUX

Material: Stainless Steel 201/304

Color: Silver

Sample: Provide

Application: Pipe Connection

-

Cold Rolled Stainless Steel Strip

Cold rolled stainless steel strip is made of hot rolled stainless steel as blank and then cold rolled. Strip and sheet steel are rolled by cold mill at normal temperature. The general thickness is 0.1 ~ 3mm, and the width is 100 ~ 2000mm. The cold-rolled strip or sheet has the advantages of good surface finish, good flatness, high dimensional accuracy and good mechanical properties. Usually the products are in rolls, and a large part of them are processed into coated steel plates. Compared with the hot rolled strip, the dimensional accuracy is higher, the surface roughness is low, the surface quality is good, the finish is high, the strength is high.

-

Stainless Steel Hose Clamp

Stainless steel hose clamp because of the selection of good steel, the production process is also relatively strong, after many strict checks at the factory, safe and reliable, in the anti-rust ability and fastening force are very strong, very durable. The product has beautiful appearance, easy operation, high free torsion force and overall torsion force, smooth edge of the throat band does not hurt the hose, stable and fast tightening, and the throat band can be reused. Stainless steel hose band classification

-

Stainless Steel Insole

Steel bottom can prevent puncture, anti-static, zigzag resistance, acid and alkali resistance, high and low temperature resistance. Quality up to EN, CSA, JIS and other international standards, is the work shoes, labor protection shoes and other protective shoes necessary protective products Stainless steel anti-puncture insole made of high quality steel, is the ideal choice for safety shoes, has good puncture resistance, can be bent more than 1,000,000 times. The surface is sprayed with epoxy resin matte powder to enhance adhesion, prevent rust and puncture. Especially in the site is particularly popular, mainly used to prevent stepping on nails or other sharp objects, due to its high hardness, wear resistance characteristics, can effectively protect the safety of the foot, reduce the risk of injury.Durable: Compared with ordinary insoles, stainless steel insoles are stronger, not easy to damage, and have a long service life.

-

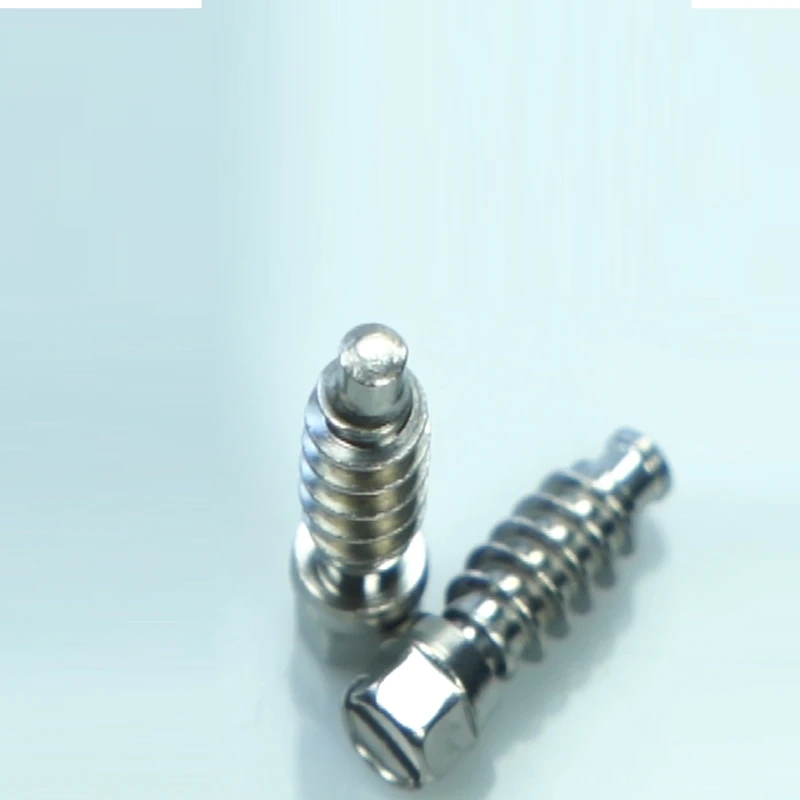

Various types of hose clamp screws

The term stainless steel screws typically refers to steel screws with the ability to resist corrosion from air, water, acids, alkalis, salt, or other corrosive mediums. Stainless steel screws are generally corrosion-resistant, durable, and find applications in environmental protection equipment, medical devices, communication equipment, and other fields.depending on the alloy composition, emphasis may vary between stainless properties and acid resistance. Some steels, while corrosion-resistant, might not necessarily be acid-resistant. Acid-resistant steels typically also possess stainless properties. In people's daily lives, the commonly referred to stainless steel is often austenitic stainless steel.The stainless steel fasteners we use primarily employ austenitic grades such as 302, 304, 316, and the "low-nickel" 201, depending on the specific requirements.

Product name:screw for hose clamp

head shape: Hexagon head screws

Corresponding standards: ISO, BS, ANSI, GB, DIN, JIS, non-standard

Specification Model: M6\M8

Material: 201, 304, 22A

Heat treatment: Carburizing and nickel plating on iron

Packing method: According to customer samples.

-

High Quality EN Standard Stainless Steel Midsole

Stainless Steel anti-puncture insoles is made from high quality steel which is ideal for safety shoes, it has good puncture

resistance and can be bent more than 1,000,000 times, its surface is made of epoxy resin matte powder spray to enhance the

adhesion, it is anti rust and anti puncture. Steel anti Piercing Mid sole has been used in safety shoe making for many years. it

is thin, inexpensive and widely used by safety shoe makers. (Steel anti-penetraion Mid sole manufactured in our factory has

Flexing resistance: (1000000 times),EN12568,CSA (1500000times)standard. Penetration resistance 1100N Flexing resistanc

100PRS/CTN). It has EUROPEAN STANDARD EN12568.

Item:stainless steel midsole

Application:For safety shoes

Material:stainless steel

Thickness:0.49mm

Color:silver

Standard:EN22568

Penetration resistance:1200N

Flexing resistance:EN22568 (1000000times)standard

Complete Stainless Steel Clamp Industrial Chain: From Raw Materials to Finished Products

Hebei Yaxin stands out as one of the few enterprises in China with a fully integrated production chain for stainless steel clamps and strips. Our in-house capabilities span raw material processing, product design, mold manufacturing, production, inspection, and packaging, ensuring strict quality control at every stage. This vertical integration allows us to offer customized solutions tailored to specific customer requirements, supported by our strong R&D team and numerous patented technologies.

Our collaboration with Yanshan University in establishing the National Cold-Rolled Strip Equipment and Process Engineering Technology Research Center further enhances our innovation capabilities, driving advancements in high-tech materials and deep-processing technologies.

High-Precision Stainless Steel Strips: Superior Performance Leading Industry Innovation

The stainless steel hose clamps produced by Hebei Yaxin have captured 70% of the domestic market share and are exported to the United States, Russia, Turkey, the Middle East, and beyond, with annual exports exceeding $6 million. Our commitment to superior quality and a robust supply chain system has positioned us as a trusted partner for global customers seeking reliable stainless steel solutions.

Your Partner for Premium Stainless Steel Products

With a focus on continuous innovation and market expansion, Hebei Yaxin Stainless Steel Products Co., Ltd. has emerged as a pioneer in the stainless steel deep-processing industry. We are dedicated to delivering high-performance stainless steel products that meet the evolving needs of diverse industries, from household appliances to automotive components.