- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

-

Global ReachBased in Xingtai City Hebei Province, we serve a global customer base. Our distribution network ensures that our products reach you no matter where you are. We're proud to support industries worldwide with our reliable hose clamps.

Global ReachBased in Xingtai City Hebei Province, we serve a global customer base. Our distribution network ensures that our products reach you no matter where you are. We're proud to support industries worldwide with our reliable hose clamps. -

Customer-Centric ApproachOur customers are at the heart of everything we do. We pride ourselves on providing excellent customer service, quick response times, and competitive pricing. Your satisfaction is our ultimate goal.

Customer-Centric ApproachOur customers are at the heart of everything we do. We pride ourselves on providing excellent customer service, quick response times, and competitive pricing. Your satisfaction is our ultimate goal. -

Join Us on the JourneyWe invite you to join us on our journey as we continue to innovate, serve, and secure. Whether you're a long-standing partner or a new customer, we look forward to providing you with the hose clamps you can trust.

Join Us on the JourneyWe invite you to join us on our journey as we continue to innovate, serve, and secure. Whether you're a long-standing partner or a new customer, we look forward to providing you with the hose clamps you can trust.

-

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

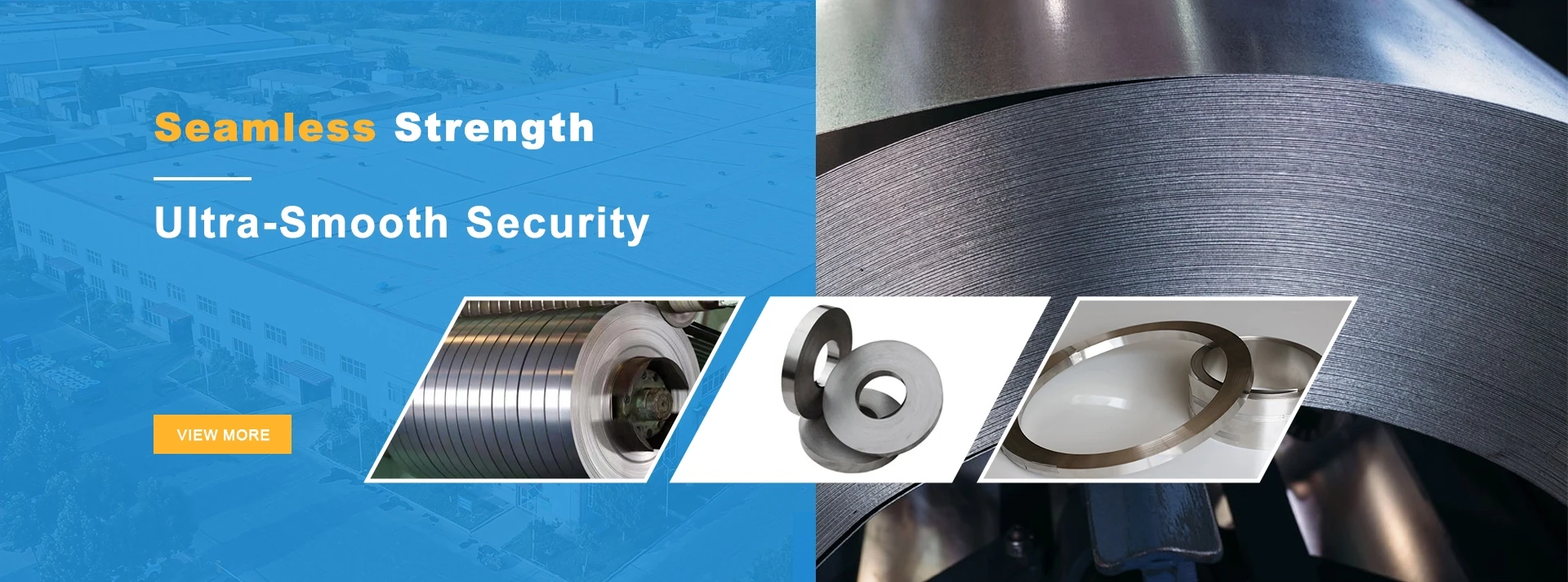

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mm

Surface Technics:2B/BA/polished/fogging surface

Quality Standard:Certificate of conformity

Packaging:Packing shall depend on the customer's requirements

Applications:Stainless steel strip produced by Hebei Yaxin Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes,hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro- parts etc.

-

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mm

Width:4-690mm

Surface Sechnics:2B/BA/polished/fogging surface

Quality Standard:Certificate of conformity

Packaging:Packing shall depend on the customer'srequirements

Applications:Stainless steel strip produced by Hebei Yaxin

Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes,hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro-parts etc.

-

The 201 and 304 stainless steel strips are distinct alloys with different compositions.

- 201 Stainless Steel Strip: It is a lower-cost alternative to 304, characterized by manganese, nitrogen, and nickel content. While it offers good corrosion resistance, it may not be as corrosion-resistant as 304. It's often used in applications where cost is a primary consideration.

- 304 Stainless Steel Strip: This is a widely used austenitic stainless steel known for its excellent corrosion resistance, high-temperature strength, and versatility. It contains chromium and nickel, providing durability and a polished appearance. 304 is commonly used in various industries, including food processing, architecture, and kitchen appliances.

The choice between 201 and 304 depends on the specific requirements of the application, considering factors such as corrosion resistance, cost, and mechanical properties.

- 202 Stainless Steel Strip: This is a type of austenitic stainless steel, similar to 201 but with increased nickel content. It offers improved corrosion resistance compared to 201, making it suitable for certain applications. However, it generally doesn't match the corrosion resistance of 304 or 316 stainless steel.

- 316 Stainless Steel Strip: Known as a marine-grade stainless steel, 316 contains molybdenum, enhancing its corrosion resistance, especially in aggressive environments. It is resistant to corrosion from acids, chlorides, and seawater, making it suitable for applications in marine, chemical, and medical industries where high corrosion resistance is crucial.

The choice between 202 and 316 depends on the specific environmental conditions and performance requirements of the application. While 201 may offer cost advantages, 316 is chosen for its superior corrosion resistance in demanding settings.

Item:Stainless Steel Strip

Material:Stainless steel 201/202/304/316

Thickness:0.1-2mmWidth:4-690mm

Surface technics:2B/BA/polished/fogging surface

Quality standard:Certificate of conformity

Packaging:Packing shall depend on the customer'srequirements

Applications:Stainless steel strip produced by Hebei Yaxin Stainless Steel Products Co.,Ltd is extensively applied in kitchenware products,glass lid,Stainless Steel Tubes, hose clamps,coil springs ,measurement instrument fabrication,armoured cable, Electronic Products and Electro-parts etc.