- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 01, 2025 02:21 Back to list

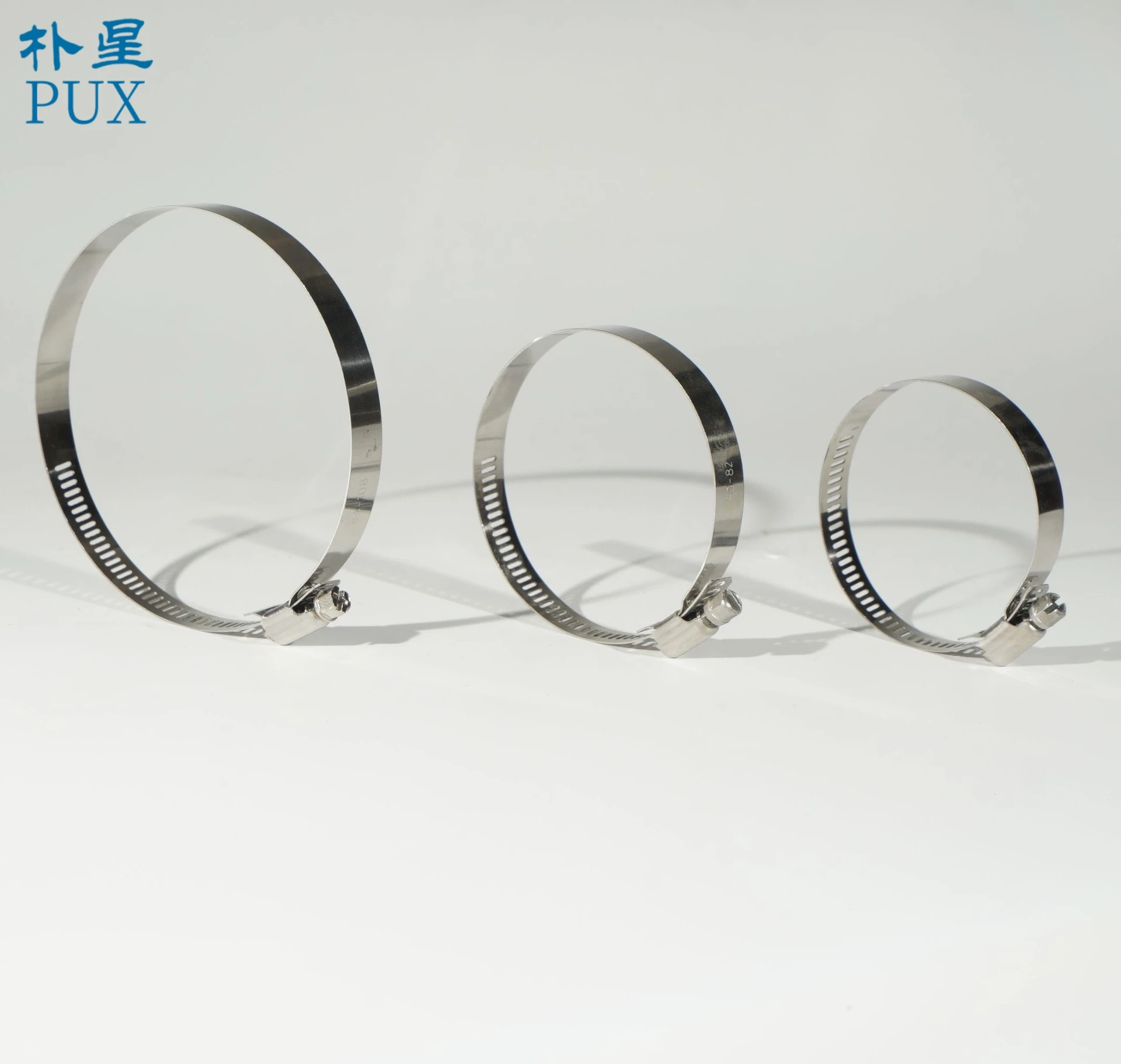

band style hose clamps

Band style hose clamps are a staple in various industries, renowned for their reliability and versatility in ensuring secure connections between hoses and fittings. These small yet crucial components may seem simple, but their design and material choices are based on extensive engineering and testing to meet diverse application needs, ranging from automotive to plumbing and beyond.

For automotive uses, these clamps are indispensable. They secure various engine and fluid transfer components, ensuring that vital systems operate efficiently and safely. Given the vibration and temperature variations in automotive environments, selecting the appropriate band style hose clamp is critical. Professionals look for specific features such as high heat resistance and enhanced flexibility to meet the rigorous demands of automotive applications. Similarly, in the plumbing industry, band style hose clamps are vital in maintaining the integrity of water or gas lines. Here, the emphasis is on ensuring leak-proof seals that comply with strict regulatory standards. The reliable performance of these clamps in maintaining system integrity without frequent maintenance demonstrates their authoritative position in this sector. Trust in band style hose clamps is built through years of consistent performance and adherence to industry standards. Manufacturers often subject these clamps to rigorous testing, including stress tests, pressure endurance, and corrosion resistance trials, ensuring that each product not only meets but exceeds industry standards. Certifications and approvals from regulatory bodies further enhance their credibility, providing professionals with peace of mind regarding their operational reliability. In summary, band style hose clamps are far more than just simple fastening tools. They are the product of meticulous engineering and quality material selection, designed to offer secure and reliable connections across various applications. Whether in automotive, plumbing, or general construction, these clamps are trusted by professionals for their durability, ease of use, and performance, serving as a quintessential element in maintaining operational integrity and safety. When choosing band style hose clamps, prioritize products that showcase superior craftsmanship and have a proven track record of excellence to ensure that your systems function flawlessly.

For automotive uses, these clamps are indispensable. They secure various engine and fluid transfer components, ensuring that vital systems operate efficiently and safely. Given the vibration and temperature variations in automotive environments, selecting the appropriate band style hose clamp is critical. Professionals look for specific features such as high heat resistance and enhanced flexibility to meet the rigorous demands of automotive applications. Similarly, in the plumbing industry, band style hose clamps are vital in maintaining the integrity of water or gas lines. Here, the emphasis is on ensuring leak-proof seals that comply with strict regulatory standards. The reliable performance of these clamps in maintaining system integrity without frequent maintenance demonstrates their authoritative position in this sector. Trust in band style hose clamps is built through years of consistent performance and adherence to industry standards. Manufacturers often subject these clamps to rigorous testing, including stress tests, pressure endurance, and corrosion resistance trials, ensuring that each product not only meets but exceeds industry standards. Certifications and approvals from regulatory bodies further enhance their credibility, providing professionals with peace of mind regarding their operational reliability. In summary, band style hose clamps are far more than just simple fastening tools. They are the product of meticulous engineering and quality material selection, designed to offer secure and reliable connections across various applications. Whether in automotive, plumbing, or general construction, these clamps are trusted by professionals for their durability, ease of use, and performance, serving as a quintessential element in maintaining operational integrity and safety. When choosing band style hose clamps, prioritize products that showcase superior craftsmanship and have a proven track record of excellence to ensure that your systems function flawlessly.

Share

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025