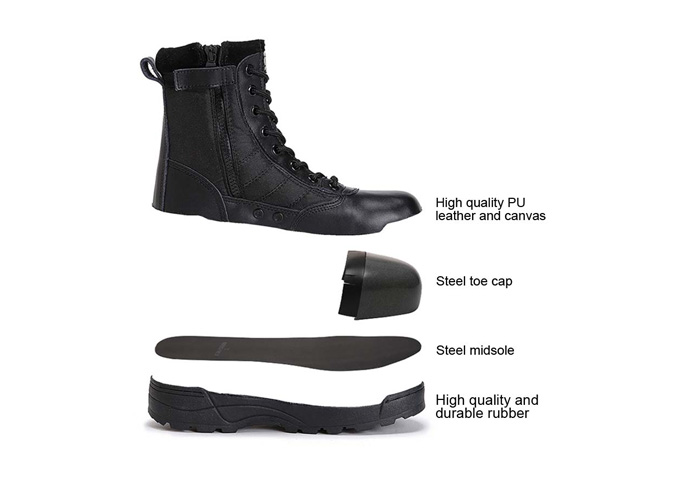

Safety midsoles for shoes Steel Plate Anti-nail Anti-piercing Foot Larbor Protection steel Midsoles

Product Selling point

1-The company owns the most advanced automatic production line in the country,achieves a high standard in delivering and deliver goods fast.

2-Large capacity,500000 pairs/month

3-The product quality is quite stable and our company is based in the logistics centers

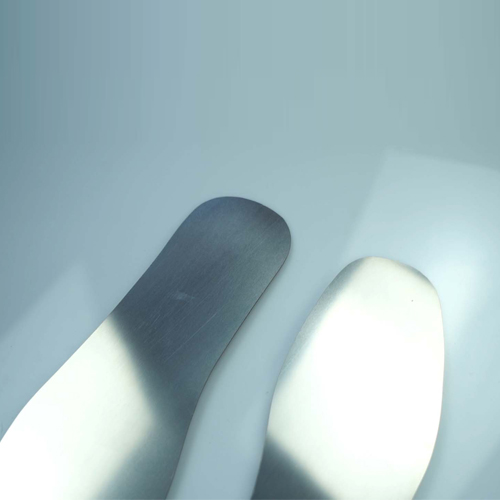

Product Presentation

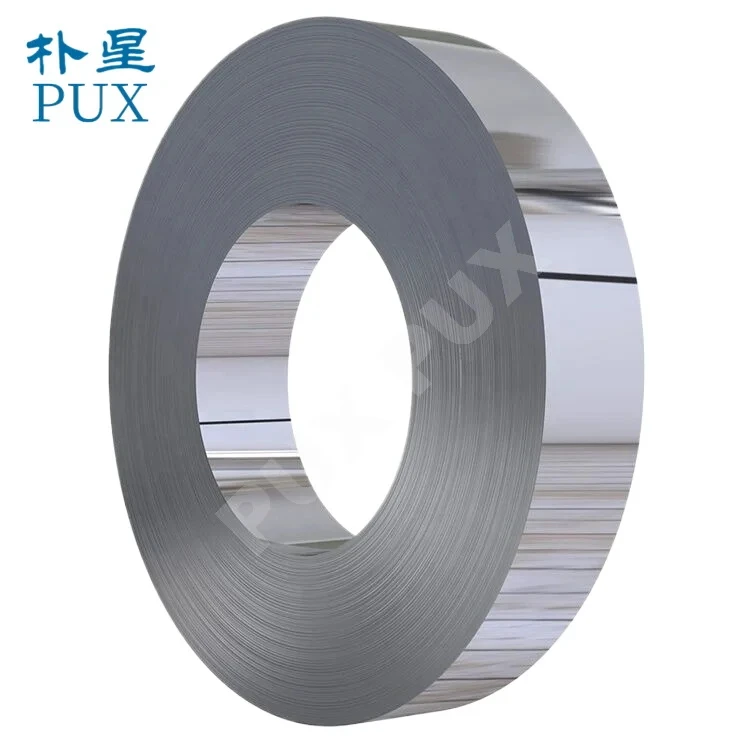

To ensure product quality ,Raw materials (Stiainless Steel Strip produced by ourselves)in the production of rigorous testing before prohibit unqualified raw materials storage and can be extraced exactly by laser cutter.All the products are standardization in manufacturing and automatic production line.In addition,the Regional Logistics is prosperous,which deliver goods fast.

Manganese steel midsoles meet EU standards for protective spray midsoles: insulation, anti-slip, nail-resistant, with a puncture force of 1200N (sprayed with insulating powder, regular powder, eco-friendly powder). Specialized for construction sites, these steel defenders guard against nails, punctures, and sharp objects, ensuring your safety.

Product Application

-

Climbing high operation in the power industry

-

For safety shoes

What is the Manganese steel(Mn steel)?

An Mn steel midsole refers to a midsole component in certain types of safety footwear, such as safety shoes or boots. The term "Mn steel" indicates that the midsole is made from manganese steel.

Manganese steel is known for its toughness and durability. In safety footwear, the midsole made of Mn steel serves as a protective layer between the insole (inner sole) and the outsole (bottom sole). The primary purpose of an Mn steel midsole is to provide resistance against puncture hazards. It acts as a barrier to prevent sharp objects like nails or glass from penetrating through the sole and reaching the foot, enhancing the overall safety of the footwear.

Safety shoes or boots with an Mn steel midsole are commonly used in work environments where there is a risk of stepping on sharp objects. This feature is particularly beneficial in industries such as construction, manufacturing, or any setting where protection against puncture hazards is crucial.