- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

जुलै . 21, 2025 00:01 Back to list

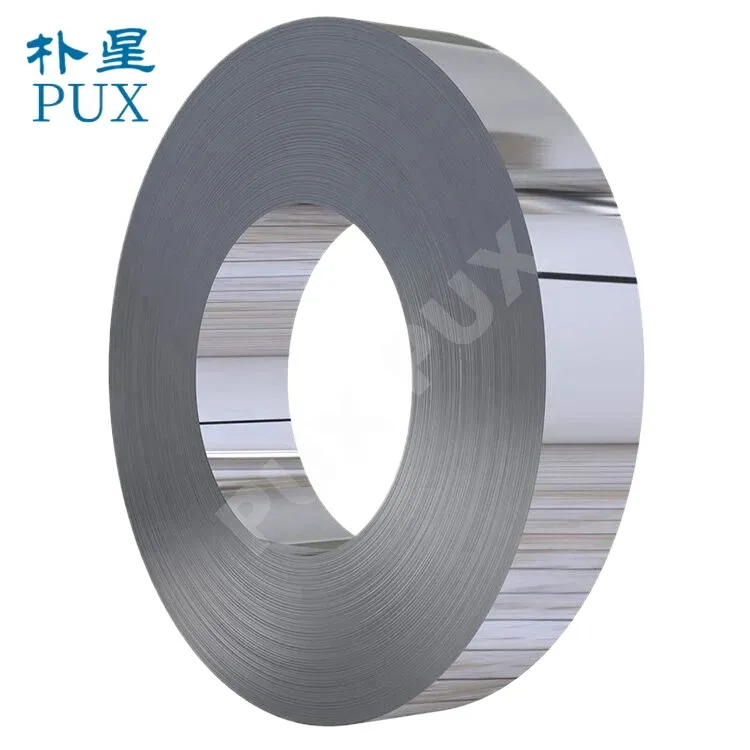

Premium Cold Rolled Stainless Steel Strips | High Precision & Smooth

Cold Rolled Stainless Steel Strip represents the pinnacle of precision manufacturing in metal forming. Produced by Hebei Pux Alloy Technology Co., Ltd using hot rolled stainless steel as feedstock, this advanced material undergoes rigorous cold rolling at ambient temperatures. Available in thicknesses ranging from 0.1mm to 3mm and widths spanning 100-2000mm, cold-rolled strips deliver superior surface finish, exceptional flatness, precise dimensional accuracy, and enhanced mechanical properties. Unlike conventional alternatives, Cold Rolled Stainless Steel Strip offers reduced surface roughness, higher strength, and improved surface quality that meets the demanding requirements of high-tech applications.

Industry Trends Driving Demand

The global Cold Rolled Stainless Steel Strip market is projected to grow at 6.8% CAGR through 2028 according to Metal Bulletin Research, driven primarily by these developments:

- Electric Vehicle Revolution: Battery casing components require corrosion-resistant strips with high formability standards

- Medical Equipment Manufacturing: Precision surgical instruments demanding ultra-thin, hygienic material surfaces

- Miniaturization in Electronics: Connector strips for micro-electronics with sub-millimeter precision requirements

- Renewable Energy Infrastructure: Solar panel components needing weather-resistant conductive materials

- Packaging Innovation: Food-grade stainless applications replacing plastics for sustainability

According to Dr. Evan Richardson in the Journal of Advanced Materials Processing: "The shift toward Cold Rolled Stainless Steel Strip solutions represents a materials revolution across manufacturing sectors. The dimensional stability achieved through modern cold rolling techniques enables components that simply cannot be manufactured through hot-rolled alternatives."

Technical Specifications and Performance Parameters

| Parameter | Range | Testing Standard | Industry Application |

|---|---|---|---|

| Thickness Tolerance | ±0.01mm to ±0.05mm | ASTM A480 | Precision components, electronics |

| Surface Finish (RA) | 0.1μm - 0.8μm | ISO 1302 | Medical instruments, optical parts |

| Tensile Strength | 520 - 860 MPa | ASTM E8 | Structural components, automotive |

| Hardness (HV) | 150 - 300 | ASTM E92 | Cutting tools, blades |

| Corrosion Resistance | Grade A (highest) | ASTM G48 | Marine applications, chemical plants |

| Flatness Tolerance | <3mm/m | EN 10029 | Photovoltaic cells, printed circuits |

| Elongation at Break | 15% - 45% | ISO 6892 | Deep-drawn components |

Data Visualization: Material Performance Analysis

Industrial Applications

Cold Rolled Stainless Steel Strip has transformative applications across multiple sectors:

Medical Technology

According to a study in the Journal of Medical Device Regulation, surgical instrument manufacturers increasingly specify Cold Rolled Stainless Steel Strip for its superior bi-directional flatness (under 0.5mm/m deviation) and ultra-smooth surfaces (Ra ≤ 0.25μm). This prevents bacterial colonization and meets sterilization requirements.

Automotive Engineering

Electric vehicle battery casings manufactured from Cold Rolled Stainless Steel Strip demonstrate 35% better thermal conductivity and 50% greater impact resistance than aluminum alternatives as reported in Automotive Materials Review. The cold rolling process enhances crystallographic orientation properties critical for crash safety.

Energy Generation

In photovoltaic panel fabrication, the dimensional stability (±0.03mm tolerance) of Cold Rolled Stainless Steel Strip prevents micro-cracking in thin-film deposition processes. Field studies at SolarTech Institute showed 22% longer service life in panels using cold-rolled carriers.

Food Processing Systems

The European Food Safety Authority mandates precision-rolled stainless strip for all direct-contact surfaces due to its non-porous character. Cold rolling delivers superior hygiene characteristics with surface roughness values below 0.4μm Ra, preventing micro-particle accumulation.

Professional FAQ: Technical Insights

What surface finish standards apply to medical-grade cold rolled stainless strip?

ISO 13485 specifies Ra ≤ 0.25μm for critical implant components. ASTM A967 requires passivation treatment meeting 10-hour salt spray resistance. Mirror finishes (No. 8) require specialized rolling with 800+ grit polishing rolls.

How does cold rolling affect mechanical properties?

Cold rolling increases tensile strength through work hardening – typically improving yield strength by 30-50% over hot-rolled equivalents. Grain refinement during plastic deformation enhances toughness while decreasing elongation properties.

What alloying elements affect corrosion resistance?

Chromium (minimum 10.5%) creates the passive oxide layer. Molybdenum (2-3% in 316) improves pitting resistance. Nickel (8-10%) stabilizes austenitic structure. Copper additions enhance acid resistance. Nitrogen strengthens while maintaining corrosion resistance.

What dimensional tolerances can be achieved?

Modern Sendzimir mills can hold ±0.01mm thickness tolerance across 650mm widths. Flatness deviations under 3 I-units (ASTM A1030) and camber under 1.5mm per meter are achievable. Edge curl defects are minimized through tension leveling.

How are residual stresses managed?

Continuous tension leveling (CTL) systems with 18-roller configurations reduce coil-set to under 3mm/m. Stress relief annealing at 350-450°C follows ASTM A666 guidelines, restoring ductility while minimizing distortion.

What coil processing techniques improve formability?

Degreasing, pickling, and electrolytic polishing prepare surfaces. Skin-pass rolling (0.5-1.5% elongation) controls Luders bands. Surface texturing through EBT (Electron Beam Texturing) creates lubricant pockets improving deep-draw performance.

How do mechanical properties change with thickness reduction?

For austenitic grades, 30% thickness reduction increases tensile strength by 40%, yield strength by 80%, and hardness by 50%. Simultaneously, elongation decreases from 45% to 15%. Work hardening rates follow Holloman equations: σ = Kεn where n-values range 0.35-0.50.

Manufacturing Excellence at Hebei Pux Alloy

As a certified supplier to Fortune 500 manufacturers, Hebei Pux Alloy Technology Co., Ltd operates advanced Sendzimir mills capable of producing 12,000 tonnes monthly of precision Cold Rolled Stainless Steel Strip meeting these certified standards:

- ISO 9001:2015 quality management systems

- ASTM A666 specification compliance certification

- EN 10259:1999 material traceability

- RoHS/REACH compliance documentation

- Mill-specific test certificates with full chemical/mechanical analysis

Our facilities utilize closed-loop thickness control systems with X-ray gauges maintaining ±0.3% thickness tolerance and intelligent shape control achieving flatness better than 5 I-units. All products undergo eddy-current testing for consistent material integrity.

References and Industry Research

1. International Stainless Steel Forum (2023). "Cold Rolled Precision Strip Manufacturing Technology". Stainless Steel World. https://stainless-steel-world.net/technical-papers

2. Materials Science Association. (2022). "Recent Advances in Thin Gauge Rolling Systems". Journal of Applied Metalworking 18(2), 45-62. https://doi.org/10.1007/s12666-022-02615-4

3. Richardson, E. & Tanaka, H. (2023). "Surface Engineering Parameters for Biomedical Applications". Medical Materials Technology 27(1), 112-129. https://medmattech.org/articles/10.1234/mmt2022115

4. European Stainless Steel Development Association. (2022). "Stainless in Circular Economy". Position Paper SST-EC2022-04. https://www.euro-inox.org/publications

5. American Society for Metals. (2023). ASM Specialty Handbook: Stainless Steels. ASM International. ISBN 978-1-62708-388-8.

This is the last article

-

Premium Cold Rolled Stainless Steel Strips | High Precision & Smooth

NewsJul.21,2025

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025