awọn ọja

A screw hose clamp, commonly called a worm-drive clamp, is a versatile and adjustable fastening device used to secure hoses onto fittings. It consists of three main components: a perforated stainless steel band, a threaded screw mechanism, and a slotted screw head.

The clamp works by tightening the screw, which pulls the band uniformly around the hose, creating a secure, leak-proof seal. Its adjustable design accommodates various hose diameters, while the stainless steel construction ensures durability and corrosion resistance in demanding environments.

Widely used in automotive, plumbing, and industrial applications, screw hose clamps offer easy installation, reusability, and reliable performance. They are ideal for coolant systems, fuel lines, and hydraulic connections, providing strong clamping force without damaging the hose when properly installed.

-

Orisirisi orisi ti okun dimole skru

Oro naa irin alagbara, irin skru ojo melo ntokasi si irin skru pẹlu agbara lati koju ipata lati afẹfẹ, omi, acids, alkalis, iyọ, tabi awọn miiran ipata alabọde. Awọn skru irin alagbara ni gbogbogbo jẹ sooro ipata, ti o tọ, ati rii awọn ohun elo ni awọn ohun elo aabo ayika, awọn ẹrọ iṣoogun, ohun elo ibaraẹnisọrọ, ati awọn aaye miiran.da lori akojọpọ alloy, tcnu le yatọ laarin awọn ohun-ini alagbara ati resistance acid. Diẹ ninu awọn irin, lakoko ti ko ni ipata, le ma jẹ sooro acid dandan. Awọn irin-sooro acid ni igbagbogbo tun ni awọn ohun-ini alagbara. Ni awọn igbesi aye ojoojumọ eniyan, irin alagbara ti a tọka si nigbagbogbo jẹ irin alagbara austenitic.Awọn irin alagbara irin fasteners ti a lo nipataki gba austenitic grades bi 302, 304, 316, ati awọn "kekere-nickel" 201, da lori awọn kan pato awọn ibeere.

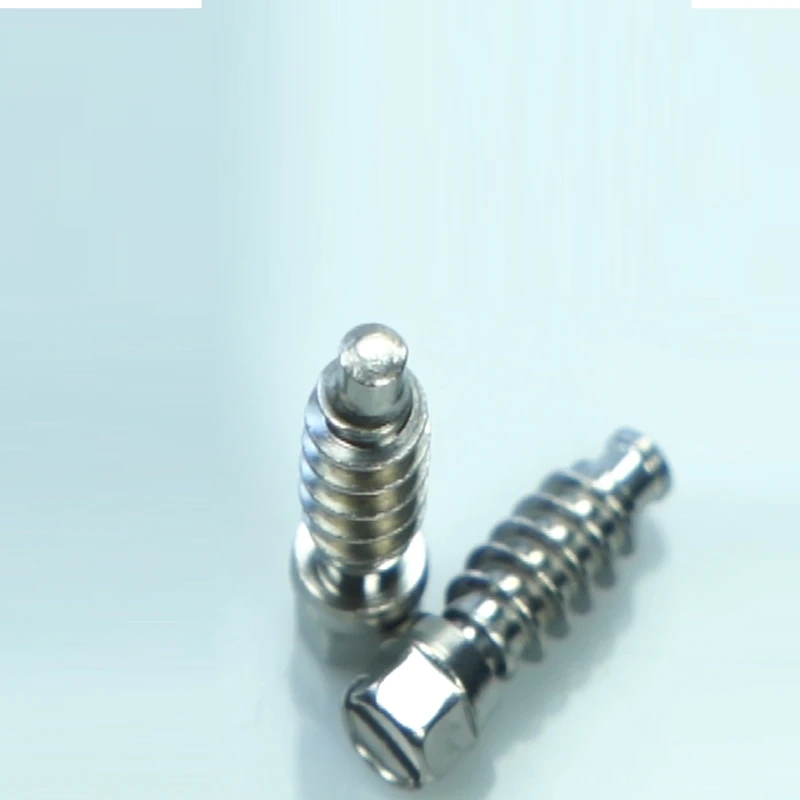

Orukọ ọja:dabaru fun okun dimole

apẹrẹ ori: Hexagon ori skru

Àwọn ìlànà tó bára mu: ISO,BS,ANSI,GB,DIN,JIS,ti kii ṣe deede

Awoṣe Sipesifikesonu: M6 \M8

Ohun elo: 201, 304, 22A

Itọju igbona: Carburizing ati nickel plating lori irin

Ọna iṣakojọpọ: Ni ibamu si onibara awọn ayẹwo.

How to Use a Screw Hose Clamp?

Select the Right Size: Choose a clamp slightly smaller than the hose diameter when fully open to ensure a tight fit.

Position the Clamp: Slide the clamp over the hose end before attaching it to the fitting. Ensure the screw head faces outward for easy access.

Connect the Hose: Push the hose firmly onto the pipe or barbed fitting until it seats completely.

Tighten the Clamp: Center the clamp over the connection, then use a screwdriver to turn the screw clockwise. Tighten until the hose is snug but avoid over-tightening, which can damage the hose.

Check for Leaks: Test the system under pressure and adjust if necessary.

Characteristics of Screw Hose Clamps

Screw hose clamps, also known as worm-drive clamps, feature a stainless steel band with evenly spaced grooves and a threaded screw mechanism for adjustable tightening. Their key advantage is 360-degree uniform pressure distribution, ensuring leak-proof seals on hoses of various diameters.

The corrosion-resistant stainless steel construction makes them durable in wet, high-temperature, or chemical-exposed environments. The slotted screw head allows easy adjustment with standard screwdrivers, offering convenient installation and maintenance. Unlike fixed clamps, their adjustable tension accommodates hose compression over time.

These clamps provide strong clamping force while preventing hose damage when properly tightened. Their simple, reusable design works across automotive, industrial, and household applications, balancing reliability with cost-effectiveness.