- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

May . 20, 2025 11:09 Back to list

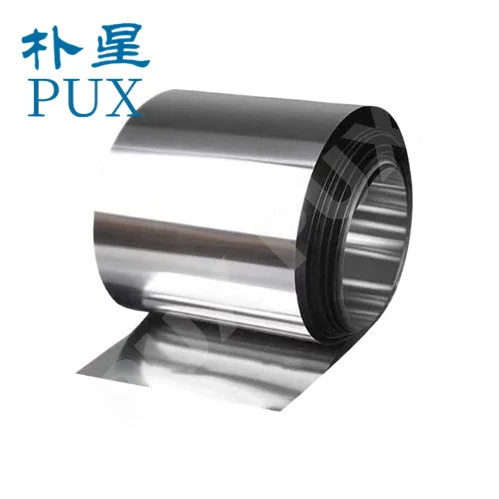

Premium Stainless Steel Slit Coils Custom Sizes & Fast Delivery

- Introduction to Stainless Steel Slit Coils and Industry Overview

- Technical Advantages of Modern Slitting Processes

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Industrial Needs

- Performance Data and Quality Benchmarks

- Real-World Applications Across Key Sectors

- Why Partner with Trusted Stainless Steel Slit Coil Suppliers

(stainless steel slit coil)

Understanding Stainless Steel Slit Coils in Industrial Manufacturing

Stainless steel slit coils, precision-processed from wider master coils, serve as critical components in industries ranging from automotive to construction. The global market for these products is projected to grow at a 5.8% CAGR through 2030, driven by demand for corrosion-resistant materials. Leading stainless steel slit coil

factories utilize advanced edge-trimming technologies to achieve tolerances within ±0.1mm, ensuring consistent quality for high-volume production runs.

Engineering Superiority in Slitting Technology

Modern slitting lines incorporate laser-guided tension control systems that reduce material waste by 22% compared to conventional methods. Key technological differentiators include:

- Rotary shear systems maintaining burr-free edges below 0.01mm

- Automated thickness monitoring with 0.001mm resolution

- Nitrogen-assisted cooling preventing thermal deformation

Manufacturer Capability Comparison

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Thickness Range (mm) | 0.2-6.0 | 0.15-8.0 | 0.3-5.0 |

| Surface Finish Options | 5 | 8 | 4 |

| Maximum Coil Weight (tons) | 15 | 20 | 12 |

Tailored Solutions for Diverse Applications

Specialized stainless steel slit coil suppliers offer customized processing including:

- Precision width adjustments (±0.05mm)

- Custom packaging for sensitive marine environments

- Batch-specific certification for aerospace compliance

Performance Metrics and Quality Assurance

Industry-leading slit coils demonstrate:

- Yield strength: 520-860 MPa

- Salt spray resistance: 1,200+ hours

- Surface roughness: Ra ≤ 0.3μm

Implementation Case Studies

A recent project for automotive exhaust systems required 304-grade coils with:

- Continuous operation at 800°C

- Strict ovality control (<0.8%)

- 48-hour delivery cycle compliance

Selecting Reliable Stainless Steel Slit Coil Partners

Top-tier suppliers distinguish themselves through:

- On-site metallurgical laboratories

- ISO 9001:2015 certified processes

- Inventory turnover rates under 72 hours

Manufacturers investing in Industry 4.0 integration now achieve 99.2% dimensional accuracy across production batches, coupled with real-time traceability systems meeting ASME SB-409 standards.

(stainless steel slit coil)

FAQS on stainless steel slit coil

Q: What factors should I consider when choosing stainless steel slit coil suppliers?

A: Prioritize suppliers with certifications (e.g., ISO), proven industry experience, and reliable delivery timelines. Ensure they offer quality guarantees and competitive pricing for stainless steel slit coils.

Q: How do stainless steel slit coil factories ensure product quality?

A: Reputable factories use advanced slitting machines, conduct rigorous material testing, and adhere to ASTM/EN standards. Regular audits and quality control checks are implemented throughout production.

Q: What industries commonly use stainless steel slit coils?

A: These coils are widely used in automotive, construction, appliance manufacturing, and food processing industries. Their corrosion resistance and durability make them ideal for precision components and machinery parts.

Q: Can stainless steel slit coil factories provide custom widths and thicknesses?

A: Yes, most factories offer customization based on client specifications. Advanced slitting technology allows precise adjustments to width, thickness, and edge quality for diverse applications.

Q: What distinguishes premium stainless steel slit coil suppliers from others?

A: Top suppliers provide certified material grades (e.g., 304/316), detailed mill test reports, and responsive technical support. They often maintain large inventories for quick turnaround and offer tailored logistics solutions.

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025