- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Aug . 06, 2024 14:31 Back to list

Leading Manufacturer of High-Quality Double Bolt Hose Clamps for Industrial Applications

The Importance of Double Bolt Hose Clamps and Their Manufacturers

In the realm of industrial and automotive applications, the significance of reliable fittings cannot be overstated. One such vital component is the double bolt hose clamp, which plays a crucial role in ensuring the secure connection of hoses to fittings. As industries increasingly prioritize efficiency and reliability, the role of double bolt hose clamp manufacturers has become more critical than ever.

Understanding Double Bolt Hose Clamps

Double bolt hose clamps are recognized for their robust design and superior holding power. Unlike single clamp designs, double bolt clamps feature two bolts that allow for even distribution of pressure around the hose. This design minimizes the risk of leaks and hose failure, making them an ideal choice for high-pressure applications. They are widely used across various industries, including automotive, marine, construction, and manufacturing.

The primary function of these clamps is to provide a secure attachment point for hoses, ensuring that fluid or gas contained within a hose does not leak under pressure. The dual-bolt system is particularly beneficial when dealing with larger diameter hoses or in situations where the hose will experience fluctuating pressures or temperatures.

The Role of Manufacturers

Manufacturers of double bolt hose clamps play a pivotal role in guaranteeing the quality and reliability of these essential components. High-quality clamps are crucial for preventing leaks that could lead to catastrophic failures or unsafe working conditions. Manufacturers must adhere to rigorous quality control measures to ensure that their products meet industry standards. This includes the selection of durable materials, precise manufacturing processes, and detailed testing procedures.

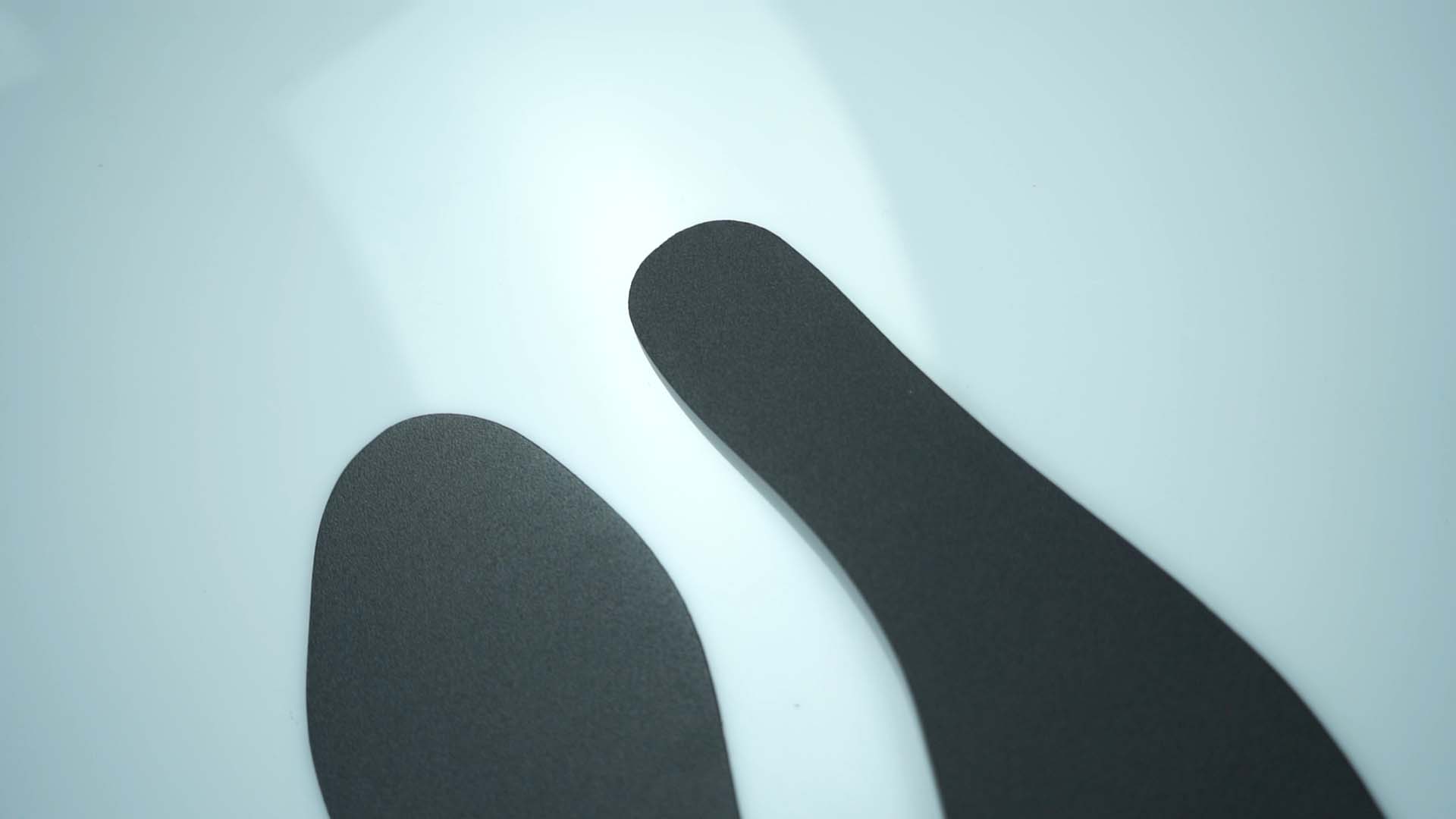

double bolt hose clamp manufacturer

A reputable manufacturer will typically source corrosion-resistant materials such as stainless steel or high-grade aluminum to produce their clamps. These materials not only enhance the durability of the clamps but also extend their lifespan, particularly in harsh environments. Manufacturers also invest in advanced engineering techniques to design clamps that are both functional and user-friendly.

Innovation and Technology in Manufacturing

With the continuous evolution of technology, the manufacturing of double bolt hose clamps has seen significant advancements. Modern manufacturers leverage computer-aided design (CAD) software to create precise prototypes, ensuring that each clamp meets the necessary specifications before mass production. Additionally, automated machinery is increasingly being utilized to enhance production efficiency and maintain consistent quality.

Sustainability is another critical focus for contemporary manufacturers. Many are now adopting eco-friendly practices, such as using recyclable materials and reducing waste during production processes. This not only fulfills corporate responsibility commitments but also caters to a growing market demand for environmentally sustainable products.

Conclusion

As industries become more reliant on high-performance components, the significance of double bolt hose clamp manufacturers is amplified. Their commitment to quality, innovation, and sustainability is essential in providing safe and effective solutions for various applications. By ensuring that these clamps are manufactured to high standards, they contribute to the overall reliability and safety of systems that depend on fluid or gas containment. Whether in automotive applications, industrial settings, or marine environments, the role of these manufacturers is vital in maintaining the integrity and performance of critical systems. Investing in high-quality double bolt hose clamps from reputable manufacturers is not just a choice; it is a necessity for safety and efficiency in today’s fast-paced world.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.06,2025

-

High Quality Steel Midsole - EN Standard for Safety Shoes

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology|[Corrosion Resistance]&[Adjustable Design]

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

Large Stainless Steel Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance&Adjustable Design

NewsAug.05,2025