- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 23, 2024 07:25 Back to list

Top Manufacturers of High-Pressure Hydraulic Hose Clamps for Reliable Performance

Understanding High Pressure Hydraulic Hose Clamps Manufacturers and Their Importance

In the realm of hydraulic systems, the significance of high-pressure hydraulic hose clamps cannot be overstated. These specialized clamps are critical components used to secure hoses and prevent leaks, ensuring the safety and efficiency of hydraulic applications across various industries. As a result, the demand for high-quality hose clamps has surged, leading to the proliferation of manufacturers dedicated to producing reliable and durable products.

The Role of High-Pressure Hydraulic Hose Clamps

High-pressure hydraulic hose clamps serve several essential functions in a hydraulic system. Primarily, they are designed to hold hoses firmly in place, preventing any potential displacement caused by the pressure of the hydraulic fluid. By securely fastening the hoses, these clamps mitigate the risk of leaks, which can lead to severe safety hazards and operational inefficiencies.

Moreover, high-pressure hydraulic hose clamps are engineered to withstand extreme conditions, including high pressure, temperature fluctuations, and exposure to various chemicals. This durability is crucial in applications such as construction machinery, industrial equipment, and automotive systems, where hoses are subjected to substantial stress.

Types of Hydraulic Hose Clamps

Manufacturers offer a variety of hydraulic hose clamps, each designed for specific applications and pressure ratings. Some common types include

1. T-Bolt Clamps These clamps feature a high-strength T-bolt that provides a secure grip on the hose. They are often used in high-pressure applications due to their ability to deliver even pressure distribution.

2. Worm Gear Clamps Widely used for their ease of installation and adjustability, worm gear clamps are suitable for medium pressure applications. They operate by tightening a screw to compress the clamp around the hose.

high pressure hydraulic hose clamps manufacturers

4. Heavy-Duty Clamps Engineered for extreme conditions, heavy-duty clamps can handle high pressure and are often utilized in industrial hydraulic systems.

Choosing the Right Manufacturer

Selecting a reliable manufacturer of high-pressure hydraulic hose clamps is crucial for ensuring quality and performance. When evaluating potential suppliers, consider the following factors

- Reputation and Experience Opt for manufacturers with a proven track record in the industry. Established companies often have extensive experience in producing high-quality products and understanding customer needs.

- Materials Used Check the materials used in the clamps. High-quality stainless steel or other corrosion-resistant materials are preferred, especially for applications exposed to harsh environments.

- Testing and Certification Ensure that the manufacturer conducts rigorous testing of their products and holds relevant certifications. This step is vital in confirming that the clamps meet industry standards for safety and performance.

- Customization Options Many applications require specific dimensions or pressure ratings. A manufacturer offering customizable solutions can provide the best fit for unique requirements.

- Customer Support Consider the level of customer service provided by the manufacturer. A responsive support team can assist with technical questions and ensure timely delivery of products.

Conclusion

High-pressure hydraulic hose clamps are integral components of hydraulic systems, ensuring operational safety and efficiency. With a growing number of manufacturers in the market, it is essential to choose a provider that prioritizes quality, reliability, and customer satisfaction. By understanding the various types of clamps available and the importance of selecting the right manufacturer, businesses can enhance the performance of their hydraulic systems and minimize the risks associated with hydraulic failures. Properly secured hoses lead to improved efficiency and long-term success in any hydraulic application.

-

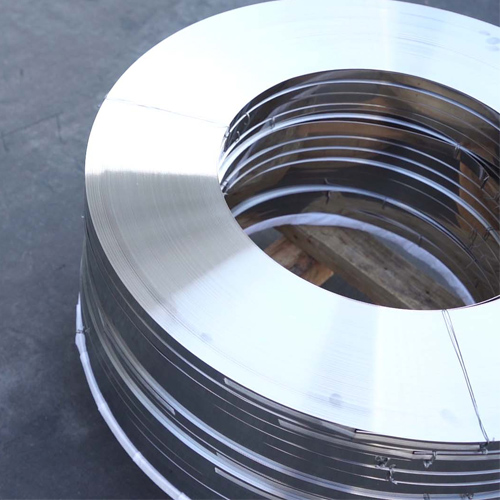

Premium Cold Rolled Stainless Steel Strips | High Precision & Smooth

NewsJul.21,2025

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025