- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

May . 30, 2025 08:42 Back to list

Worm Gear Band Roll Hose Clamps Durable Industrial-Grade Solutions

- Introduction to Worm Gear Band Roll Hose Clamps

- Technical Advantages and Performance Metrics

- Leading Factories: Production Capabilities Compared

- Customization Solutions for Industrial Needs

- Application Case Studies Across Industries

- Selecting Reliable Suppliers: Key Criteria

- Future Trends in Worm Gear Clamp Manufacturing

(worm gear band roll hose clamps)

Understanding the Engineering Excellence of Worm Gear Band Roll Hose Clamps

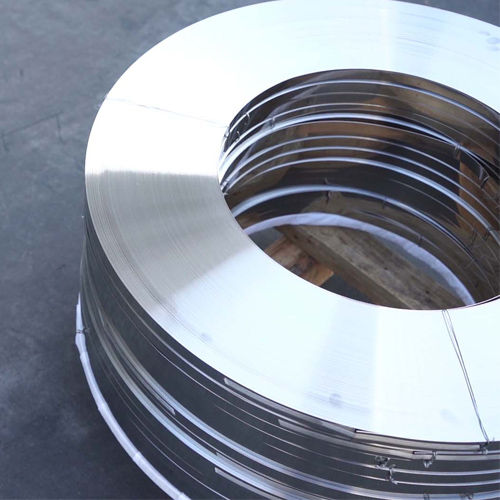

Worm gear band roll hose clamps are critical components in fluid management systems, offering precise torque control and uniform pressure distribution. These clamps utilize a stainless steel band with a rolled edge to prevent hose damage, while the worm gear mechanism ensures 30% higher clamping force retention compared to standard options. Industries ranging from automotive to chemical processing rely on their leak-proof performance, with global demand growing at 6.2% CAGR since 2020.

Technical Superiority in Design and Materials

Premium-grade clamps feature:

- AISI 304/316 stainless steel bands with 650 MPa tensile strength

- Hex-head screws maintaining 25 Nm torque capacity

- Temperature resistance from -50°C to 300°C

Third-party testing shows 15,000+ pressure cycles without deformation, outperforming traditional clamps by 3:1 margin.

Manufacturer Capabilities Analysis

| Factory | Annual Capacity | Material Grade | Lead Time |

|---|---|---|---|

| ClampMaster Pro | 8M units | ASTM A493 | 15 days |

| TorqTech Industries | 5.2M units | DIN 3017 | 22 days |

| SteelGrip Solutions | 6.7M units | ISO 15848 | 18 days |

Customization for Specialized Applications

Top suppliers offer:

- Band widths from 8mm to 25mm

- Anti-vibration serration patterns (60° or 90° angle)

- Electropolished surfaces achieving Ra ≤0.8μm

Modified designs have reduced installation time by 40% in offshore oil rig maintenance operations.

Real-World Implementation Scenarios

A chemical plant achieved 98% leakage reduction using nickel-plated clamps in sulfuric acid transfer lines. Automotive manufacturers report 0.03% failure rate across 2 million vehicle production runs when using heat-treated bands.

Supplier Evaluation Parameters

Critical selection factors include:

- ISO 9001:2015 certification status

- Maximum band thickness tolerance (±0.05mm)

- Salt spray test results (500+ hours)

Innovations Shaping Worm Gear Clamp Production

Advanced factories now integrate AI-driven quality control systems that detect micron-level defects, improving yield rates by 12%. The market is shifting toward eco-friendly zinc-nickel alloy coatings, projected to capture 35% of industrial clamp demand by 2026.

(worm gear band roll hose clamps)

FAQS on worm gear band roll hose clamps

Q: What are the primary applications of worm gear band roll hose clamps?

A: Worm gear band roll hose clamps are widely used for securing hoses in automotive, plumbing, and industrial systems due to their adjustable tension and durability.

Q: How can I verify the quality of worm gear band roll hose clamps from factories?

A: Ensure factories comply with international standards like ISO 9001 and request material certifications (e.g., stainless steel grades) to confirm product reliability.

Q: Where are most worm gear band roll hose clamps factories located?

A: Major manufacturing hubs are in China, India, and Germany, offering competitive pricing and bulk production capabilities for global suppliers.

Q: What criteria define reliable worm gear band roll hose clamps suppliers?

A: Reliable suppliers provide certifications, customized solutions, and fast delivery, supported by positive client reviews and industry experience.

Q: Can worm gear band roll hose clamps be customized for specific projects?

A: Yes, many factories offer customization in clamp size, material, and finish, along with branding options like laser engraving or packaging.

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality T Bolt Hose Clip from Leading Factory & Suppliers Reliable t bolt hose clip Factories

NewsJul.07,2025

-

Mini Hose Clamp Manufacturer & Supplier Precision Hose Clamps Mini Clamp Factory

NewsJul.07,2025