- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

جولائی . 27, 2025 21:01 Back to list

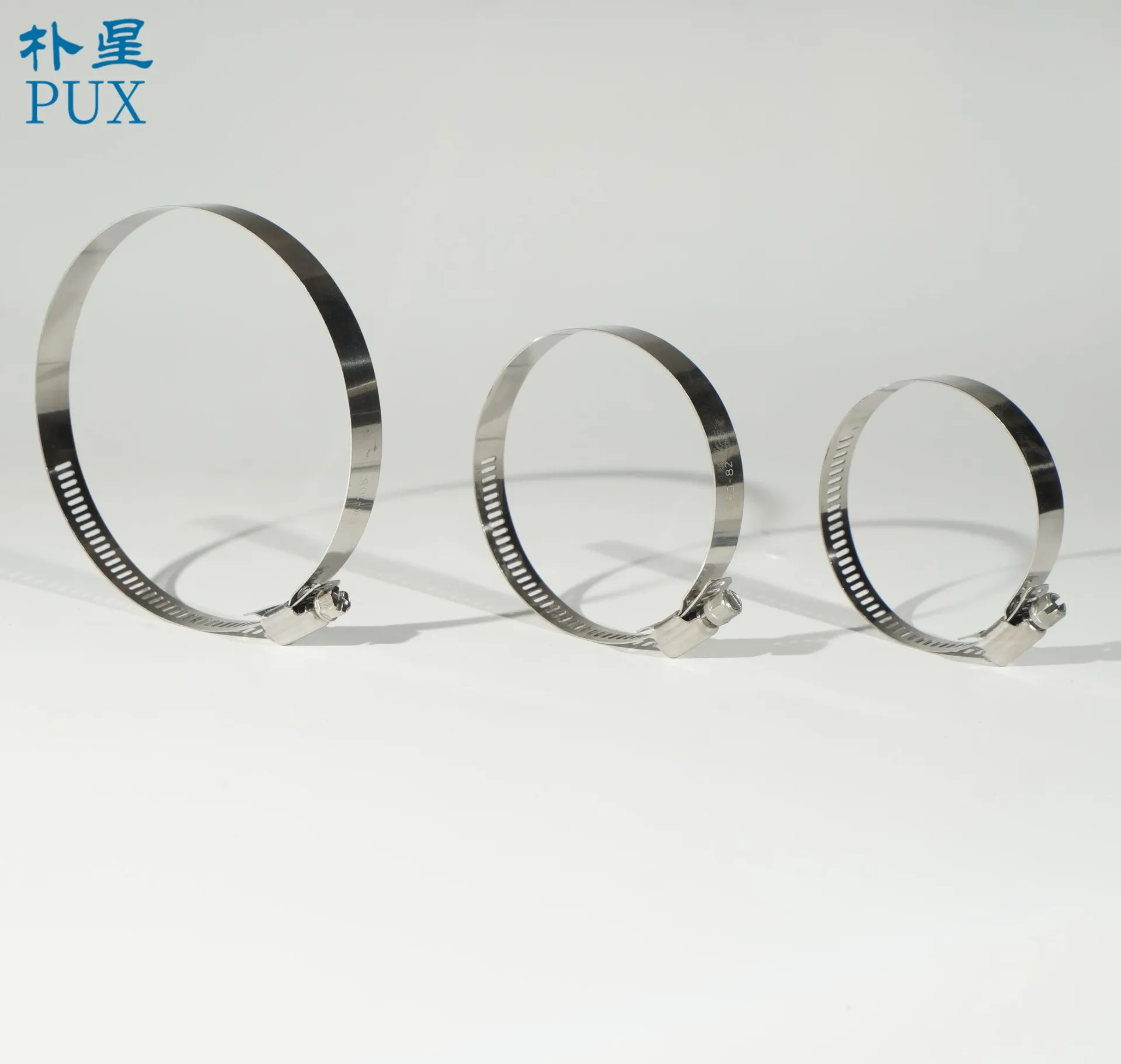

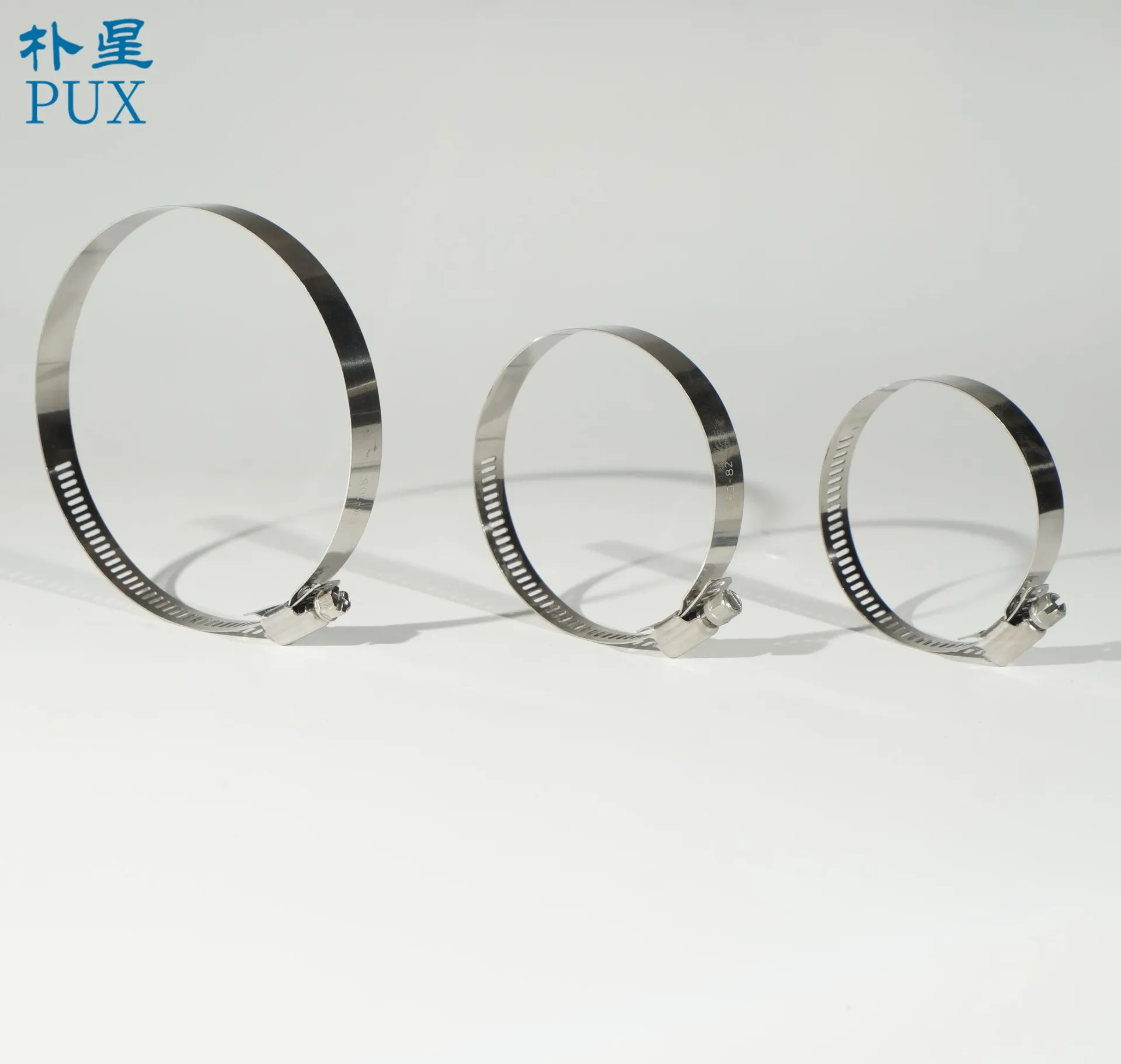

Premium Stainless Steel Hose Clamp for Automotive & Industrial Use

Discover why stainless steel hose clamps remain the backbone of secure, leak-proof connections across critical sectors including petrochemical, automotive, HVAC, metallurgy, and potable water systems.

Industry Overview & Market Trends

According to the Global Hose Clamps Market Report (2023), the global hose clamp market size exceeded USD 2.23 billion in 2022 and is projected to grow at a CAGR of 5.7% through 2028. Among these, stainless steel hose clamps account for over 61% of market share, driven by demand in corrosive and high-performance environments.

The growth is fueled by stricter fluid system safety regulations, expanding automotive production, and intensive infrastructure investments worldwide.

Leading manufacturers increasingly focus on advanced manufacturing methods, tighter dimensional tolerances, and compliance with ISO/ANSI/DIN standards to cater to global markets.

Technical Specifications & Product Range

Stainless steel hose clamps are precision-engineered fasteners designed to secure hoses over fittings, preventing leaks and ensuring system integrity. Common materials include SS304 and SS316 stainless steel, offering outstanding resistance against corrosion and high/low temperature tolerance.

Typical applications demand strict compliance with international standards, such as:

- ISO 9227 - Corrosion resistance (salt spray)

- ANSI/ASME B18.2.1 - Fastener dimensional specifications

- SAE J1508 - Automotive hose clamp requirements

- 1 inch stainless steel hose clamps

- 2-4 inch heavy-duty clamps

- 10 inch stainless steel hose clamps

- Adjustable stainless steel hose clamp (8 - 44 inch)

- Miniature, worm-drive, and T-bolt designs

| Specification | Typical Value | Standard/Reference |

|---|---|---|

| Material | SS304 / SS316 | ASTM A240, EN 10088 |

| Band Width | 8mm, 12mm, 14mm, 16mm | SAE J1508, DIN 3017 |

| Band Thickness | 0.6 - 1.2mm | Manufacturer Spec, ISO 9227 |

| Adjustable Range | 8mm - 250mm | Product Line Specific |

| Torque, Max | 4 - 9 Nm | SAE J1508 |

| Corrosion Resistance | >240 Hours (Salt Spray) | ISO 9227 |

| Clamp Type | Worm-drive, T-bolt, Quick-release | Industry Standard |

Technical Performance Trend – 2018 to 2023

Manufacturing Process of Stainless Steel Hose Clamp

Technical Advantages & Industry Certifications

- Corrosion Resistance: Over 240 hours in neutral salt spray (according to ISO 9227).

- Wide Working Range: Reliable clamping from 8mm up to 250mm (10 inch stainless steel hose clamps).

- Mechanical Strength: Rated to >9 Nm torque and >1800N tensile force.

- Precise Adjustability: Fine thread worm-drive mechanism delivers leak-tight fitting at low torque.

- Environmental Compliance: RoHS, REACH certified; safe for potable water and food applications (FDA passivation).

- Longevity: Field data shows >10 years service in oil & gas and utility sectors with scheduled maintenance.

- Certified Processes: Plants certified to ISO 9001:2015 / ISO 14001; product lines with CE and SGS certification.

- Traceability: All batches marked for full lifecycle tracking and quality assurance.

- Customizable Designs: Available with locking tabs, reinforced bands, quick-release mechanisms.

Major Manufacturer Comparison: Stainless Steel Hose Clamps

| Manufacturer | Material Options | Size Range | Certifications | OEM/Custom | Warranty |

|---|---|---|---|---|---|

| Puxing Clamp (China) | SS304, SS316, SS201 | 8-250mm | ISO 9001, SGS, CE | YES | 3 Years |

| Norma Group (Germany) | SS304, SS316 | 8-190mm | ISO 9001, TS16949 | YES | 2 Years |

| BREEZE (USA) | SS304, SS430 | 6-120mm | ISO 9001 | Limited | 2 Years |

| Mikalor (Spain) | SS304, SS316 | 10-240mm | CE, ISO 14001 | YES | 2 Years |

Custom Solutions: Tailored Stainless Steel Hose Clamp Designs

For critical or non-standard projects, adjustable stainless steel hose clamp options can be provided with:

- Special Material Grades: Duplex/Super Duplex for chemical exposure, custom alloy for ultra-low temperature.

- Coatings: PTFE, epoxy for extra chemical/protective performance.

- Logo & Color Coding: Supports OEM branding, color-coded sleeves for line identification.

- Dimension/Band Width: Up to 300mm, custom widths for high-pressure or specialty hoses.

- Bulk/Kitting Options: Kits assembled by customer P/N, bagging, retail or industrial packaging.

Application Scenarios: Data-Driven Case Studies

* Project: 42–inch flexible crude-transfer lines at offshore oil terminal.

* Solution: 10 inch stainless steel hose clamps (SS316, double-banded with locking tab).

* Impact: 38% reduction in hose coupling leaks over 24 months; lowered emergency downtime by 19% (source: Lloyds Register audit).

Case 2: Automotive Cooling Systems – Germany & USA

* Project: High-volume OEM passenger vehicle platform.

* Product: Automotive hose clamps stainless steel (SAE J1508 spec., torqued at 4.5 Nm).

* Impact: 5-year zero-failure record across 180,000 units; recognized by VDA (German Auto Association).

Case 3: Potable Water Network – South East Asia

* Solution: 1 inch stainless steel hose clamps (SS304 with FDA passivated finish).

* Effect: Maintained

Typical Application Industries

- Oil & Gas (Transfer hose connections)

- Automotive (Radiator & fuel line securement)

- Chemical Processing (Anti-corrosive clamping)

- Building Plumbing & Drainage (Long-life water systems)

- Food & Beverage (Sanitary hose assemblies)

- Marine Shipbuilding (Salt-resistance critical)

- General Industry (Compressed air, vacuum)

Stainless Steel Hose Clamp: Frequently Asked Questions

What does SS304 vs SS316 signify for stainless steel hose clamps?

SS304 provides excellent general corrosion resistance; SS316 offers superior resistance to chlorides and chemicals, making it ideal for marine and chemical plant applications.What size range is available for 1 inch vs 10 inch stainless steel hose clamps?

1 inch stainless steel hose clamps suit smaller tubing (8-27mm range), while 10 inch types secure hoses up to 250mm or larger, depending on band design.Are adjustable stainless steel hose clamp models suitable for all environments?

Adjustable varieties (mini to extra-large) are suitable for most environments, but seawater or aggressive chemicals require SS316 or special alloy grades.What international standards apply to automotive hose clamps stainless steel?

Automotive clamps should comply with SAE J1508, ISO 9227 (corrosion testing), and OEM torque requirements for safe, leak-free performance.What is the typical installation torque for stainless steel hose clamps?

Standard worm-drive designs: 3-5 Nm for 8-52mm clamps, higher (up to 9 Nm) for heavy-duty/large-diameter types. Always follow product datasheet recommendations.How long is the warranty/expected service life?

Premium products (SS304/316) offer 2-3 year warranties, with service life exceeding 8–12 years subject to installation and media.Can stainless steel hose clamps be customized for special media (chemical, high-temp)?

Yes. Options include special passivation, PTFE-coated bands, extra-wide designs, and bulk packaging tailored to technical requirements.

Delivery, Warranty & Customer Support

- Standard Delivery: 7–21 days ex-works (subject to batch size or custom design requirement).

- Quality Assurance: 100% dimensional and torque testing prior to packing; batch traceable inspection certificates provided.

- Warranty: 2–3 years for material and manufacturing defects (contact customer support for claims).

- Customer Support: 24/7 technical hotline; engineering application advice and free installation guides.

- Global Shipping: Options for express/air freight, sea LCL/FCL; eco packaging with full documentation.

Conclusion & Further Reading

The stainless steel hose clamp remains a fundamental yet technologically advanced component indispensable to safe, leak-free, and reliable fluid system operation. Choice of material, precise manufacturing, and robust quality management are critical for maximizing lifecycle value—supported by standards compliance and proven field performance.

For deeper technical insights and independent expert reviews, explore:

This is the last article

-

Premium Stainless Steel Hose Clamp for Automotive & Industrial Use

NewsJul.27,2025

-

Heavy Duty Hose Clamp – Durable Stainless Steel Automotive Tube Clip

NewsJul.26,2025

-

High Quality Precision Stainless Steel Strip for Industrial Use

NewsJul.25,2025

-

Black Rubber Hose Clamp with Rubber Lined & Insulated Design for Secure Fitting

NewsJul.24,2025

-

High Quality Steel Stainless Midsole for Safety Shoes Supplier

NewsJul.23,2025

-

High Quality Hose Clamps Mini Clips - German Style & Stainless Steel

NewsJul.22,2025