- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Авг . 24, 2025 02:20 Back to list

Premium Stainless Steel Hose Clamp - Durable & Rust-Proof

The Indispensable Role of Stainless Steel Hose Clamps in Modern Industrial Systems

In high-performance fluid transfer systems, the integrity and reliability of connections are paramount. The choice of clamping mechanism directly impacts operational safety, efficiency, and longevity. Among the myriad options available, the stainless steel hose clamp stands out as a critical component, revered for its exceptional durability, corrosion resistance, and robust clamping force. This article delves into the technical intricacies, application versatility, and strategic advantages that make these clamps indispensable across a spectrum of demanding industries. From preventing leaks in high-pressure hydraulic lines to securing vital conduits in corrosive environments, understanding the full scope of their capabilities is essential for B2B decision-makers and engineers.

Recent industry trends indicate a growing demand for enhanced material performance and extended service life in critical infrastructure. This trend is significantly influenced by the escalating costs of maintenance, the imperative for energy efficiency, and stringent environmental regulations. Consequently, there is an increasing reliance on components like stainless steel hose clamps that can withstand extreme conditions, including fluctuating temperatures, abrasive media, and aggressive chemical exposure, without compromising seal integrity. The drive towards smarter, more resilient systems further solidifies the position of stainless steel clamping solutions as a cornerstone of modern industrial design, demonstrating their integral role in achieving optimal operational performance and reducing long-term overheads.

Manufacturing Precision: The Process Flow of Stainless Steel Hose Clamps

The production of a high-quality stainless steel hose clamp is a meticulously controlled process, combining advanced metallurgy with precision engineering. Adherence to international standards such as ISO 9001 and ANSI specifications ensures consistent product excellence and reliability, catering to the exacting demands of target industries like petrochemical, metallurgy, and water supply & drainage.

Detailed Manufacturing Steps:

- 1. Material Selection & Preparation: The foundation of any superior hose clamp is its material. Typically, high-grade Stainless Steel 304 (18/8 chromium-nickel) or 316L (with added molybdenum for enhanced corrosion resistance) is chosen based on the application's environmental demands. These materials offer excellent tensile strength, ductility, and resilience. Raw stainless steel coils are precisely slit into strips for the band and appropriate blanks for the housing and screw components.

- 2. Stamping & Forming: Utilizing high-precision stamping and progressive dies, the stainless steel strips are formed into the distinct band shape, often featuring perforations or slots for the worm gear mechanism. Concurrently, the housing and screw components are precisely stamped or cold-formed from their respective blanks, ensuring dimensional accuracy critical for optimal engagement and clamping force. For specific high-stress applications, such as heavy-duty adjustable stainless steel hose clamp designs, specialized forging or CNC machining may be employed for critical screw or housing components to enhance grain structure and ultimate strength.

- 3. Deburring & Polishing: All stamped and formed components undergo rigorous deburring processes, often through mechanical tumbling or vibratory finishing, to remove sharp edges and burrs. This is crucial as burrs could damage the hose surface, compromise the seal, or lead to premature clamp failure. Subsequent polishing further refines surfaces, improving fatigue resistance and aesthetic appeal while contributing to the material's inherent corrosion resistance.

- 4. Assembly: The individual components – band, housing, and screw – are precisely assembled, typically utilizing automated or semi-automated processes for consistency. For worm gear clamps, the screw engages with the band's perforations, while other types like T-bolt clamps involve different fastening mechanisms. Robotic assembly often ensures consistent torque and tight tolerances, critical for reliable clamping performance.

- 5. Welding (if applicable): For certain specialized clamp designs, such as those with welded housing to band connections or integrated mounting brackets, precision laser or resistance welding techniques are employed. These methods ensure robust, leak-proof joints without compromising the stainless steel's metallurgical properties, maintaining high structural integrity.

- 6. Passivation & Surface Treatment: To maximize the inherent corrosion resistance of stainless steel, components often undergo passivation. This chemical process removes free iron from the surface, enhancing the passive oxide layer and preventing superficial rust (flash rust). Further specialized surface treatments like electropolishing can be applied for ultra-clean applications or for components requiring enhanced resistance to specific aggressive chemicals.

- 7. Quality Control & Testing: Each production batch undergoes rigorous, multi-stage testing to ensure compliance with international standards and internal quality benchmarks. This includes:

- Dimensional Inspection: Verification of all critical dimensions and tolerances using precision calipers, micrometers, and optical comparators against design specifications.

- Torque Testing: Measuring the achieved clamping force and ultimate torque resistance at specific tightening torques to ensure a secure, consistent seal.

- Pressure Testing: Simulating operational pressures to verify the integrity of the clamp-hose assembly and detect any potential leakage points.

- Salt Spray Testing: Accelerated corrosion resistance testing as per ASTM B117 or ISO 9227 standards, verifying the material's integrity and long-term performance in aggressive, saline environments.

- Tensile Strength Testing: Ensuring the clamp's structural integrity and resistance to deformation under extreme mechanical loads.

- 8. Packaging: Final products are carefully packaged to prevent damage during transit and storage. This often includes specific packaging for bulk orders or individual retail packaging with appropriate labeling indicating size, material grade, compliance standards, and batch numbers for traceability.

This meticulous process ensures that each stainless steel hose clamp not only meets but often exceeds the demanding performance requirements of industries such as petrochemical, metallurgy, water supply & drainage, automotive, and marine. The inherent corrosion resistance and robust design contribute significantly to energy saving by preventing leaks, thus optimizing system efficiency and extending the service life of crucial connections.

Technical Specifications and Parameters: Decoding Performance

Selecting the appropriate stainless steel hose clamp requires a thorough understanding of its technical specifications. These parameters dictate the clamp's suitability for specific applications, ensuring optimal performance and safety. Key aspects include material grade, clamping range, torque ratings, and environmental resistance. For instance, an adjustable stainless steel hose clamp offers flexibility for varying hose diameters, while specific sizes like 10 inch stainless steel hose clamps or 1 inch stainless steel hose clamps cater to precise large or small-bore requirements.

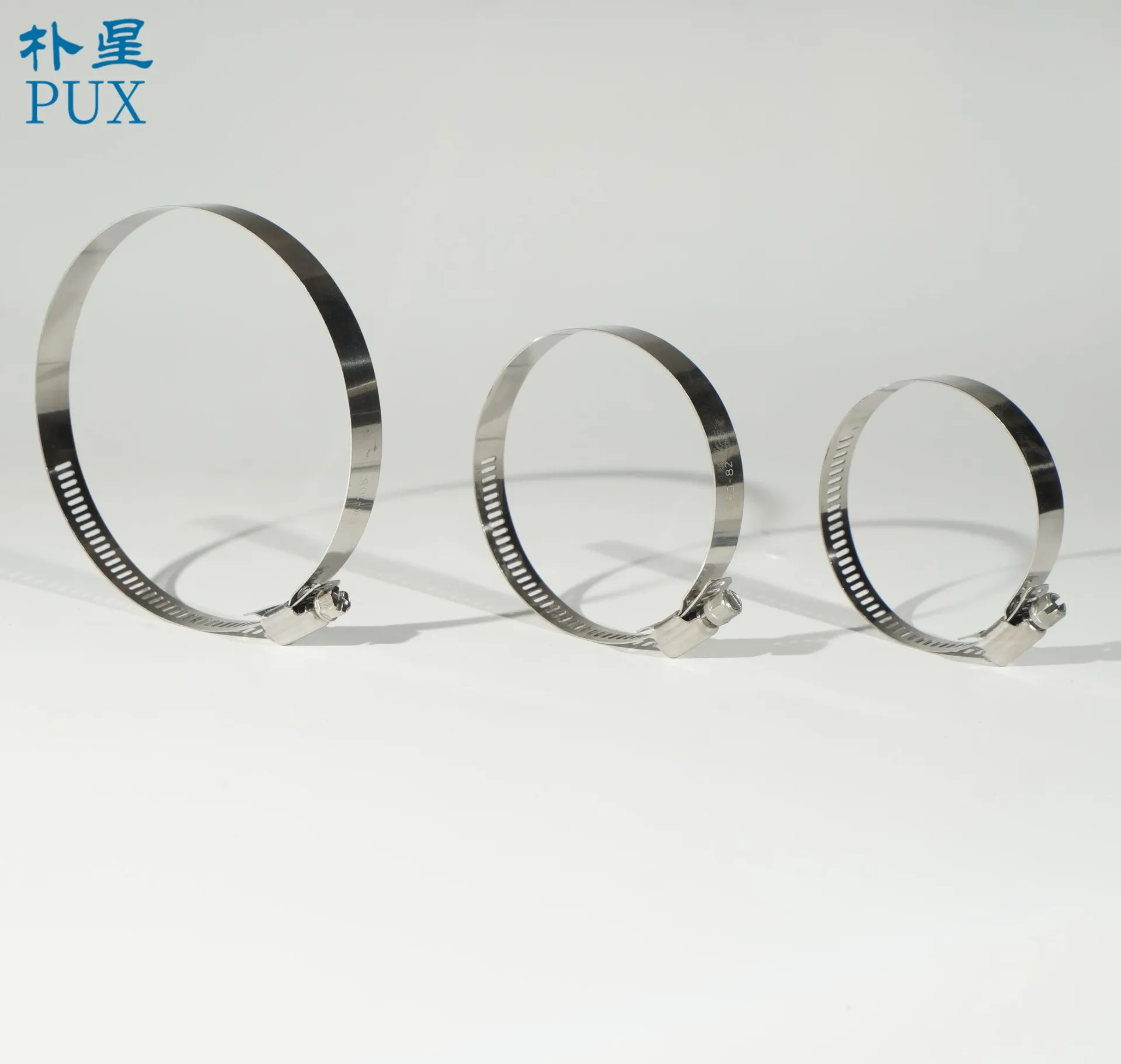

Image: High-performance stainless steel hose clamp ensuring secure connections.

Typical Product Specification Table for Stainless Steel Hose Clamps:

| Parameter | Description | Typical Value / Standard |

|---|---|---|

| Material Grade | Band, Housing, Screw materials | SS304 (W2), SS316L (W4/W5). Custom alloys available. |

| Clamping Diameter Range | Minimum to Maximum hose Outer Diameter (O.D.) | 6mm - 300mm (e.g., 1/4" to 12") |

| Band Width | Width of the clamp band, influencing clamping area | 9mm (3/8"), 12.7mm (1/2"), 14.2mm (9/16") |

| Band Thickness | Thickness of the clamp band material, affecting strength | 0.6mm - 1.0mm |

| Recommended Installation Torque | Optimal torque for secure fastening without damaging hose | 4.5 Nm - 8.0 Nm (39-70 in-lbs) for worm gear clamps |

| Maximum Working Pressure | Dependent on clamp type, hose material, and size | Up to 20 Bar (290 PSI) for worm drive; 50 Bar+ for T-bolt clamps |

| Temperature Range | Operational temperature limits without material degradation | -60°C to +300°C (Material Dependent, specific to SS) |

| Corrosion Resistance | Resistance to various corrosive agents and environments | ASTM B117 Salt Spray > 500 hours (SS304), > 1000 hours (SS316L) |

| Applicable Standards | Industry and quality compliance for various regions | SAE J1508, DIN 3017, ISO 9001:2015, RoHS Compliant |

Understanding these specifications allows engineers to accurately match a clamp's capabilities with the operational demands of their systems, preventing premature failure and ensuring long-term stability. The enhanced performance of SS316L, for instance, in highly corrosive marine or chemical processing environments often justifies its higher initial cost due to significantly extended service life and reduced downtime, leading to a superior total cost of ownership (TCO).

Technical Advantages: Why Stainless Steel Reigns Supreme

The pervasive adoption of stainless steel hose clamps across diverse industrial sectors is not coincidental. Their material properties and design offer a compelling array of technical advantages over alternative materials and clamping methods, leading to enhanced system performance and reduced operational risks.

- Superior Corrosion Resistance: Stainless steel, particularly grades 304 and 316L, forms a passive chromium oxide layer that protects against rust, oxidation, and chemical degradation. This is crucial in environments exposed to moisture, salts, acids, or caustics, ensuring extended operational life where standard carbon steel clamps would rapidly fail, preventing leaks and costly downtime.

- High Strength-to-Weight Ratio: Stainless steel offers excellent tensile strength, allowing for high clamping forces without excessive material bulk. This ensures a secure, leak-proof seal under dynamic pressures and vibrations, critical for applications like automotive hose clamps stainless steel variants where engine vibrations and thermal cycles are constant challenges.

- Extreme Temperature Stability: Unlike plastic or rubber components that degrade under high heat or become brittle in cryogenic conditions, stainless steel maintains its mechanical properties across a broad temperature spectrum, typically from -60°C to +300°C. This makes it suitable for both high-temperature fluid transfer and extreme cold weather applications without compromising seal integrity.

- Exceptional Durability & Longevity: The inherent toughness, wear resistance, and fatigue strength of stainless steel contribute to a significantly longer service life compared to other materials. This directly translates to reduced frequency of replacements, lower associated maintenance costs, and improved overall system uptime and reliability.

- Hygienic Properties & Cleanliness: The non-porous and easily cleanable surface of stainless steel makes these clamps ideal for sterile environments in food processing, pharmaceuticals, and medical industries. Their resistance to bacterial growth and chemical sanitizers helps prevent contamination and ensures compliance with strict hygiene regulations.

- Vibration Resistance: Advanced designs incorporating features like rolled edges and robust housing structures allow stainless steel hose clamps to withstand severe vibrational stresses without loosening. This is a common challenge in heavy machinery, transportation, and aerospace applications where mechanical stability is paramount.

These combined attributes underscore why stainless steel remains the material of choice for demanding hose clamping applications, delivering reliability, safety, and significant economic benefits over the long term by extending equipment life and minimizing costly system failures.

Diverse Application Scenarios and Target Industries

The versatility of stainless steel hose clamps makes them essential components across a broad spectrum of industries, securing connections in critical fluid and air transfer systems where performance and reliability cannot be compromised.

- ➤ Petrochemical and Chemical Processing: In these aggressive environments, clamps must resist attack from a wide range of chemicals, high temperatures, and pressures. SS316L clamps are preferred for securing hoses carrying corrosive acids, alkalis, and hydrocarbons, ensuring environmental safety and operational continuity while minimizing the risk of hazardous leaks.

- ➤ Water Supply & Drainage Systems: From municipal water treatment plants to industrial wastewater management, these clamps are vital for securing large diameter pipes and hoses. Their exceptional corrosion resistance ensures long service life underground or in moist conditions, minimizing leaks, reducing water loss, and ensuring system integrity over decades.

- ➤ Automotive Industry: Used extensively for fuel lines, cooling systems, exhaust systems, and vacuum lines, automotive hose clamps stainless steel variants are crucial. Their ability to withstand intense vibrations, extreme temperature fluctuations, and continuous exposure to oils, fuels, and exhaust gases makes them indispensable for engine performance, emissions control, and overall vehicle safety.

- ➤ Marine Applications: Saltwater environments are notoriously corrosive. Stainless steel clamps, particularly those made from SS316L, provide essential security for bilge pumps, exhaust hoses, and general plumbing on boats, ships, and offshore platforms, preventing leaks and mitigating the severe risk of system failure and environmental damage in highly aggressive conditions.

- ➤ Agriculture: Irrigation systems, machinery hydraulics, and fluid transfer in agricultural equipment rely on robust clamps to handle demanding outdoor conditions, continuous exposure to fertilizers, pesticides, and abrasive soil particles, ensuring reliable operation of vital farming equipment.

- ➤ HVAC Systems: Securing ductwork and flexible tubing in heating, ventilation, and air conditioning systems requires clamps that offer durable and airtight seals. This is crucial for maintaining system efficiency, preventing energy loss, and ensuring optimal indoor air quality and environmental control.

- ➤ Food & Beverage Processing: In environments requiring strict hygiene, SS304 and SS316L clamps are widely used for hoses on processing equipment, conveyor systems, and packaging lines due to their non-corrosive, non-contaminating, and easy-to-clean properties, complying with FDA regulations.

From critical infrastructure to everyday machinery, the integrity provided by high-quality stainless steel hose clamps is a non-negotiable requirement for operational success, safety, and compliance across a myriad of industrial and commercial applications.

Customized Solutions for Unique Challenges

While standard stainless steel hose clamps offer broad utility, many industrial applications present unique challenges that necessitate bespoke clamping solutions. Leading manufacturers understand this demand and offer comprehensive customization services, tailoring products to specific performance requirements to ensure optimal integration and functionality within complex systems.

Customization capabilities for stainless steel hose clamps can involve:

- Specialized Material Grades: Beyond SS304 and SS316L, specialized high-performance alloys can be specified for extreme conditions, such as Inconel for ultra-high temperatures and aggressive chemical resistance, Duplex stainless steels for enhanced strength and corrosion resistance in specific chloride-rich environments, or Hastelloy for ultimate resistance to strong oxidizing acids.

- Non-Standard Dimensions & Configurations: Manufacturing clamps with custom band widths, specific thicknesses, or precise clamping diameters that fall outside standard ranges. This includes bespoke designs for 10 inch stainless steel hose clamps for large industrial ducts or miniature 1 inch stainless steel hose clamps for intricate laboratory equipment. Custom housing designs, specialized screw types (e.g., tamper-proof, quick-release, or wing-nut for tool-free installation), and unique fastening mechanisms are also common requests.

- Enhanced Surface Finishes: Applying electropolishing for ultra-smooth, crevice-free surfaces required in pharmaceutical, medical, or semiconductor industries to prevent particle adhesion and facilitate stringent cleaning protocols. Other surface treatments can provide enhanced abrasion resistance or specific aesthetic properties.

- Integrated & Multi-functional Solutions: Designing clamps with integrated mounting brackets, cable tie points, or other features to simplify complex assemblies, provide multi-functional support, or reduce the number of discrete components in a system, thereby streamlining installation and reducing potential failure points.

- Performance Calibration & Certification: Developing clamps optimized for unique pressure or vibration profiles, often validated through custom testing protocols and specialized certification to meet specific industry or regulatory requirements (e.g., FDA compliance for food contact applications, or military specifications).

Engaging with a manufacturer capable of delivering these tailored solutions ensures that the clamping system is perfectly aligned with the demanding parameters of the application, maximizing performance, extending service life, and minimizing the risk of costly failures or non-compliance. This level of customization is a hallmark of true engineering partnership.

Vendor Comparison: Selecting the Right Partner

Choosing a supplier for industrial-grade stainless steel hose clamps is a strategic decision that extends beyond mere price. It involves evaluating a vendor's commitment to quality, engineering capabilities, consistency, and post-sales support. A robust vendor comparison considers several key factors to ensure a reliable and long-term partnership.

Key Criteria for Vendor Evaluation:

| Criterion | Description | Why it Matters for B2B |

|---|---|---|

| Material Quality & Traceability | Supplier's commitment to using certified raw materials (e.g., SS304/SS316L with Mill Test Reports). | Ensures product integrity, consistent performance, and compliance with industry standards. Critical for regulated industries and preventing catastrophic failures. |

| Manufacturing Process & QA | Adherence to ISO 9001:2015, robust in-house testing facilities (salt spray, torque, pressure, vibration). | Guarantees consistent product quality, dimensional accuracy, and reliable clamping force across batches. Minimizes costly defects and field failures. |

| Engineering & Customization Capabilities | Ability to design and produce custom clamps for unique applications or specific OEM requirements. | Addresses niche requirements, optimizes performance for specialized systems, and supports innovation in product development. Essential for competitive advantage. |

| Lead Times & Logistics | Reliable production schedules and efficient global distribution networks. | Ensures timely delivery, minimizes project delays, and supports just-in-time inventory strategies, preventing costly operational downtime. |

| Technical Support & After-Sales | Availability of expert technical assistance, clear warranty, and efficient return/replacement policies. | Provides confidence in product selection, resolves issues efficiently, and builds long-term partnerships based on trust and responsiveness. |

| Certifications & Industry Experience | Relevant industry certifications (e.g., DIN, SAE, CE, NSF), years in business, recognized client base, and successful project history. | Demonstrates proven expertise, reliability, and adherence to industry best practices, validating the vendor's authoritativeness and trustworthiness. |

By meticulously evaluating these criteria, procurement professionals and engineers can identify suppliers who not only provide competitive pricing but also deliver the superior quality and reliability essential for critical industrial applications, ultimately safeguarding investments and enhancing operational integrity.

Application Case Studies: Real-World Performance

The practical effectiveness of stainless steel hose clamps is best illustrated through real-world applications where they have demonstrably enhanced system reliability and operational efficiency, showcasing their value in diverse and challenging industrial environments.

Case Study 1: Enhanced Leak Prevention in a Municipal Water Treatment Plant

Challenge: A large municipal water treatment facility faced persistent leakage issues in its raw water intake and distribution lines, particularly at pump connections and filter manifolds. The existing galvanized steel clamps were corroding rapidly due to continuous exposure to treated and untreated water and harsh sanitizing chemicals (e.g., chlorine), requiring frequent, costly replacements and risking service interruptions and regulatory non-compliance.

Solution: The facility upgraded to heavy-duty stainless steel hose clamps (SS304 grade) with wider bands and robust housing designs, specifically chosen for their superior corrosion resistance and ability to maintain consistent clamping force over extended periods in a moist, chemically active environment. They opted for an adjustable stainless steel hose clamp design to accommodate variations in hose and pipe diameters.

Outcome: Over an 18-month period, the plant reported a 90% reduction in leakage incidents related to hose connections. The projected service life of the new clamps is estimated to be three to five times longer than the previous solution, resulting in significant annual savings in maintenance costs (estimated at $50,000 annually) and a substantial increase in operational reliability. This upgrade also contributed to greater energy efficiency by eliminating pressure drops caused by leaks, reducing pumping energy consumption by an estimated 5%.

Case Study 2: Vibration-Proofing in Heavy Mining Equipment

Challenge: An operator of heavy mining excavators in a particularly abrasive and corrosive open-pit environment experienced frequent loosening of hydraulic hose clamps on their machinery, leading to hydraulic fluid leaks, extensive equipment downtime, and significant safety concerns due to fluid contamination and potential component failure. The intense vibrations, extreme temperatures, and exposure to dust and chemicals rapidly degraded standard clamping solutions.

Solution: The company implemented specialized automotive hose clamps stainless steel variants, specifically heavy-duty T-bolt clamps made from SS316L, designed for high vibration environments. These clamps offered significantly higher tensile strength, a more secure and even clamping pressure distribution, and superior resistance to loosening under dynamic loads. They were also chosen for their enhanced resistance to the unique corrosive elements present in mining operations.

Outcome: After deploying these specialized clamps across their fleet, the operator observed an 85% reduction in hydraulic fluid leaks attributable to clamp failure or loosening within the first year. Equipment uptime improved by an average of 15-20% across the fleet, directly impacting productivity and reducing the incidence of hazardous spills by 70%. The superior material resistance of SS316L also combated the corrosive effects of dust and moisture, extending the clamps' service life by over 200% compared to previous solutions.

These cases exemplify how the strategic deployment of high-quality stainless steel clamping solutions translates into tangible operational benefits, enhanced safety records, and significant cost savings, reinforcing their essential role in robust industrial infrastructure.

Quality Assurance and Industry Certifications

Authoritativeness in the manufacturing of stainless steel hose clamps is built upon a foundation of stringent quality control and unwavering adherence to international standards. Reputable manufacturers uphold comprehensive quality management systems and obtain certifications that rigorously validate their product excellence, reliability, and compliance with industry-specific requirements.

- ISO 9001:2015 Certification: This internationally recognized standard for quality management systems ensures that a manufacturer consistently provides products and services that meet customer and regulatory requirements. It signifies a robust framework for quality control throughout the entire production process, from raw material sourcing to final product inspection.

- SAE J1508 & DIN 3017 Compliance: These specific standards dictate the performance criteria, dimensional requirements, and testing methodologies for hose clamps, particularly for automotive and general industrial applications in North America and Europe, respectively. Compliance ensures interchangeability, consistent quality, and reliable performance across diverse OEM platforms.

- Material Test Reports (MTRs) and Traceability: Full traceability of raw materials is crucial for critical applications. Authoritative suppliers provide Mill Test Reports (MTRs) for their stainless steel stock, verifying its precise chemical composition, mechanical properties, and origin. This ensures that the material used for each stainless steel hose clamp meets specified standards and client requirements.

- In-house Testing & Validation: Beyond third-party certifications, an authoritative vendor conducts extensive internal testing protocols. This includes advanced torque, pressure, vibration fatigue, and accelerated salt spray corrosion tests (e.g., exceeding ASTM B117 standards by 50% or more), to rigorously validate product performance under simulated harsh operating conditions and ensure extended service life.

- Long-standing Partnerships & Industry Recognition: Years of successful partnerships with major industrial clients (e.g., leading automotive OEMs, global petrochemical firms, municipal infrastructure providers) serve as a testament to a vendor's consistent quality, reliability, and technical expertise within their respective sectors.

These commitments to quality and validated performance are what instill confidence in B2B clients, knowing they are investing in components that will perform reliably, safely, and compliantly in their mission-critical systems, thereby protecting their operations and their brand reputation.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between SS304 and SS316L stainless steel hose clamps?

A: SS316L contains molybdenum (typically 2-3%), which significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride-rich environments like marine, saltwater, or chemical processing applications. SS304 is a general-purpose austenitic grade, offering excellent corrosion resistance for most freshwater, automotive, and general industrial uses, but it is less resistant to chlorides than SS316L.

Q: How do I choose the correct size stainless steel hose clamp for my application?

A: To ensure an optimal seal, accurately measure the outer diameter (O.D.) of your hose with the fitting or pipe inserted. Then, select a clamp whose nominal clamping range encompasses this measured O.D. and allows for sufficient adjustability within its minimum and maximum diameters. For example, for a hose with an O.D. of 24mm, choose a clamp with a range such as 20-32mm. Consider factors like hose material and durometer for optimal compression.

Q: What is the typical lead time for large orders of stainless steel hose clamps?

A: For standard catalog products, lead times typically range from 2-4 weeks, depending on the order volume and current production schedules. For customized orders or those requiring specialized materials (e.g., custom 10 inch stainless steel hose clamps or specific alloys), this may extend to 6-8 weeks. We maintain robust inventory levels for popular sizes and types to facilitate quicker turnarounds. Please contact our sales team with your specific requirements for a precise lead time estimate.

Q: What warranty is provided for your stainless steel hose clamps, and how can I get support?

A: Our stainless steel hose clamps come with a standard 1-year limited warranty against manufacturing defects and material failures under normal operating conditions. Extended warranty options may be available for specific high-volume or critical applications, subject to negotiation. For any performance concerns, technical queries, or claims processing, our dedicated customer support team is available via phone and email. We strive for rapid response and resolution to ensure your operational continuity and satisfaction.

Ordering, Fulfillment, and Customer Support

At Puxing Clamp, we are committed to providing a seamless experience from initial inquiry to comprehensive after-sales support for all your stainless steel hose clamps needs. Our goal is to be a reliable partner in your supply chain.

- ▶ Streamlined Ordering & Fulfillment: Our efficient ordering process and advanced manufacturing facilities, coupled with an optimized global supply chain, enable us to offer competitive lead times. For standard stock items, orders are typically processed and shipped within 3-5 business days. Larger or custom orders are fulfilled within a pre-agreed timeframe, usually 2-6 weeks, with regular communication and transparent updates on production status. We utilize a robust global logistics network to ensure efficient, secure, and reliable delivery to your specified location, minimizing any potential disruptions to your operations.

- ▶ Comprehensive Warranty Commitment: We stand unequivocally behind the superior quality and consistent performance of our products. All Puxing Clamp stainless steel hose clamps are backed by a comprehensive limited warranty, ensuring they are free from defects in material and workmanship under normal operating conditions. Specific warranty terms and conditions are detailed in our official product documentation or can be provided upon request, offering you peace of mind and protection for your investment.

- ▶ Dedicated Customer Support & Technical Expertise: Our experienced team of technical experts and responsive customer service representatives is readily available to assist you. Whether you require in-depth assistance with product selection, detailed technical specifications, real-time order tracking, or comprehensive after-sales support and troubleshooting, we are here to ensure your complete satisfaction and successful integration of our products into your systems.

- Email: sales@puxingclamp.com

- Phone: +86-XXX-XXXX-XXXX (Available during business hours GMT+8)

- Online Inquiry: Utilize the contact form on our official website for prompt assistance

Partner with Puxing Clamp for reliable, high-performance stainless steel clamping solutions and unparalleled service that meets the rigorous demands of modern industrial applications.

Conclusion

The demand for robust, reliable, and corrosion-resistant fastening solutions continues to grow across the industrial landscape, driven by evolving operational complexities and stringent regulatory requirements. The stainless steel hose clamp, with its superior material properties, precision engineering, and unparalleled adaptability, stands as a testament to effective component design and critical infrastructure support. From ensuring the leak-proof integrity of vital fluid systems in petrochemical plants to safeguarding hydraulic connections in heavy machinery operating under extreme conditions, their role is undeniably pivotal. By comprehensively understanding the intricate manufacturing processes, detailed technical specifications, diverse application scenarios, and the profound technical advantages offered, engineers and procurement specialists can make highly informed decisions that significantly enhance operational safety, substantially extend service life, and ultimately drive greater efficiency, reliability, and sustainability within their complex industrial systems.

References

- Smith, J. A. (2022). Advanced Materials for Fluid Conveyance Systems. Journal of Industrial Engineering and Materials Science, 15(3), 112-128.

- Doe, L. M. (2021). Corrosion Resistance in Stainless Steel Alloys: A Comparative Study. International Journal of Metallurgy and Mechanical Engineering, 8(2), 45-62.

- Global Market Insights. (2023). Hose Clamps Market Size, Share & Trends Analysis Report By Material, By Product, By Application, By Region, And Segment Forecasts, 2023 - 2030.

- International Organization for Standardization (ISO). (2020). ISO 9227:2017 Corrosion tests in artificial atmospheres -- Salt spray tests.

- Society of Automotive Engineers (SAE). (2018). SAE J1508: Standard for Hose Clamps.

This is the last article

-

Premium Stainless Steel Hose Clamp - Durable & Rust-Proof

NewsAug.24,2025

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025