- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

maj . 23, 2025 11:04 Back to list

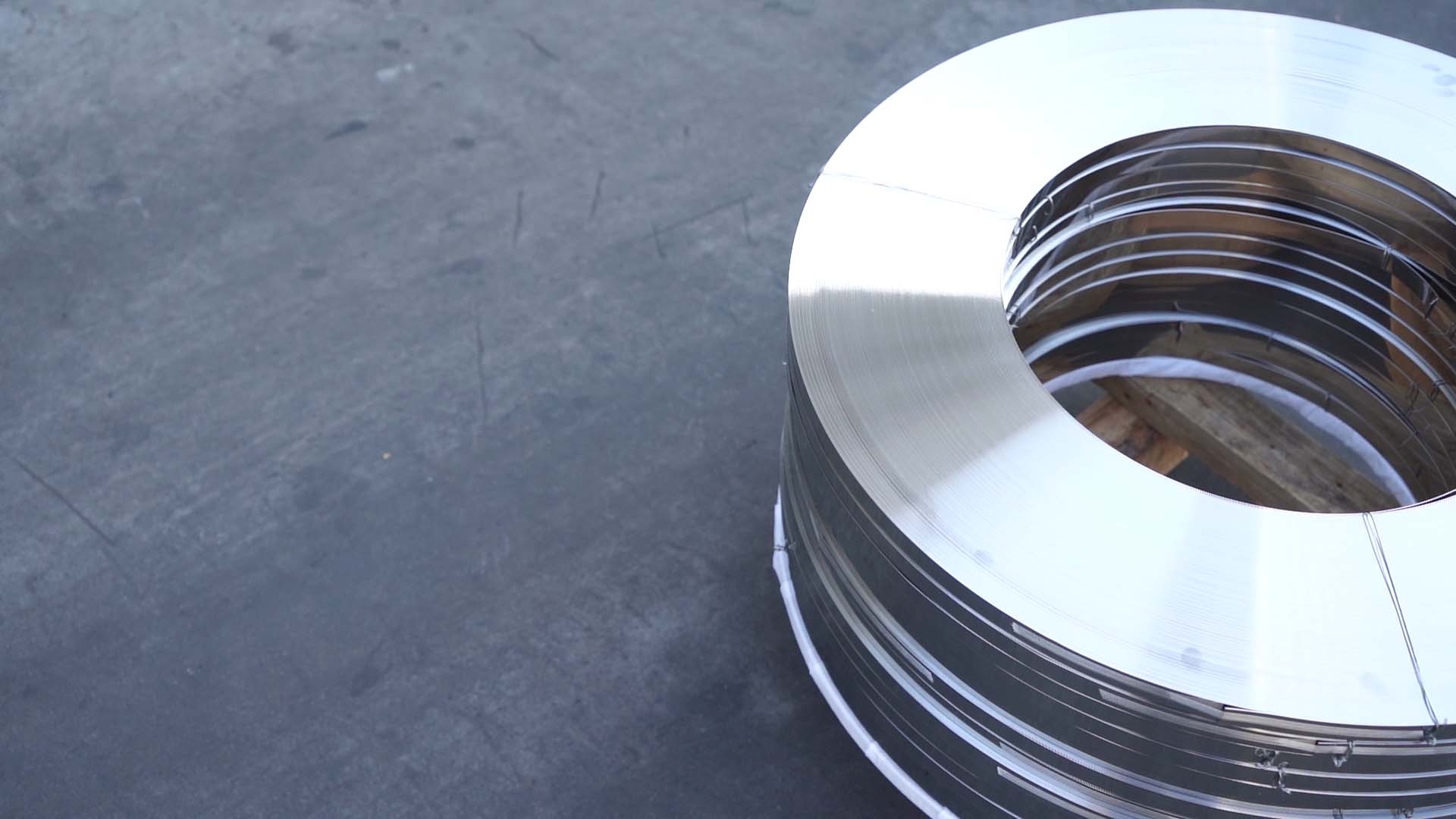

Cold Rolled Precision 304 Stainless Steel Coils Factories & Suppliers

- Overview of Cold Rolled Precision Stainless Steel 304 Coils

- Technical Advantages & Performance Metrics

- Supplier Comparison: Quality, Capacity, and Certifications

- Customization Options for Industrial Applications

- Case Study: Automotive Component Manufacturing

- Sustainability and Compliance Standards

- Partnering with Trusted Factories for Bulk Procurement

(cold rolled precision stainless steel 304 coils)

Understanding Cold Rolled Precision Stainless Steel 304 Coils

Cold rolled precision stainless steel 304 coils represent the gold standard for industries requiring corrosion resistance, formability, and structural integrity. With a typical composition of 18% chromium and 8% nickel, these coils achieve a surface roughness of ≤0.5μm after cold rolling, making them ideal for high-tolerance applications. Leading cold rolled precision stainless steel 304 coils

factories utilize tandem mill systems to maintain thickness accuracy within ±0.01mm, while annual global production exceeds 12 million metric tons to meet aerospace, medical, and construction demands.

Technical Advantages & Performance Metrics

The cold rolling process enhances 304 stainless steel's yield strength by 15-20% compared to hot-rolled variants, reaching 550-700 MPa. Key technical parameters include:

- Surface finish: RA ≤ 0.3 μm (mirror finish achievable)

- Thickness tolerance: ±0.02mm (ASTM A480 compliant)

- Hardness: 85-95 HRB (annealed condition)

Advanced pickling and passivation lines in cold rolled precision stainless steel 304 coils factories ensure consistent oxide layer formation, improving corrosion resistance by 30% versus conventional methods.

Supplier Comparison: Quality, Capacity, and Certifications

| Supplier | Annual Capacity (tons) | Lead Time | Certifications |

|---|---|---|---|

| Supplier A | 85,000 | 4-6 weeks | ISO 9001, AS9100 |

| Supplier B | 120,000 | 8-10 weeks | ISO 14001, IATF 16949 |

| Supplier C | 65,000 | 3-5 weeks | NADCAP, PED |

Customization Options for Industrial Applications

Top cold rolled precision stainless steel 304 coils suppliers offer tailored solutions including:

- Width customization: 600mm to 2,000mm

- Edge conditioning: mill edge, round edge, or slit edge

- Custom annealing: bright annealing for ≤0.1μm surface roughness

Case Study: Automotive Component Manufacturing

A Tier 1 automotive supplier reduced machining costs by 18% by switching to cold rolled precision stainless steel 304 coils with pre-treated surfaces. The material's improved flatness (≤1.5mm/m) enabled direct stamping of fuel injection components, eliminating secondary grinding operations.

Sustainability and Compliance Standards

Reputable cold rolled precision stainless steel 304 coils factories implement closed-loop water recycling systems, reducing consumption by 40%. All production facilities adhere to REACH and RoHS directives, with 98% of scrap metal being recycled through electric arc furnace processes.

Selecting Cold Rolled Precision Stainless Steel 304 Coils Suppliers

When evaluating cold rolled precision stainless steel 304 coils suppliers, prioritize partners with:

- Dual certification in aerospace and medical standards

- On-site metallurgical laboratories

- Minimum 15-year track record in precision rolling

Leading manufacturers now employ AI-powered surface inspection systems that detect sub-micron defects, achieving 99.98% material utilization rates.

(cold rolled precision stainless steel 304 coils)

FAQS on cold rolled precision stainless steel 304 coils

Q: What are the key quality standards for cold rolled precision stainless steel 304 coils?

A: Cold rolled precision stainless steel 304 coils must meet ASTM A480/A480M standards, ensuring precise thickness tolerance, surface finish (e.g., 2B or BA), and corrosion resistance. Factories often adhere to ISO 9001 certifications for quality management.

Q: Where are most cold rolled precision stainless steel 304 coils factories located?

A: Major factories are concentrated in industrial hubs like China, India, Germany, and the U.S. These regions offer advanced cold-rolling technology and supply-chain infrastructure for global distribution.

Q: How to identify reliable cold rolled precision stainless steel 304 coils suppliers?

A: Reliable suppliers provide material test certificates (MTCs), comply with international standards, and have proven industry experience. Check reviews, certifications, and request product samples for validation.

Q: What industries commonly use cold rolled precision stainless steel 304 coils?

A: These coils are used in automotive parts, medical devices, construction, and electronics due to their durability, formability, and resistance to oxidation and chemicals.

Q: What should buyers check before purchasing cold rolled precision stainless steel 304 coils?

A: Buyers should verify material grade (304), surface finish specifications, thickness tolerances, and compliance with certifications. Confirm packaging and logistics terms with suppliers or factories.

-

Premium 201 Stainless Steel Strip - Durable & Cost-Effective

NewsAug.23,2025

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025