- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

aug. . 03, 2025 03:40 Back to list

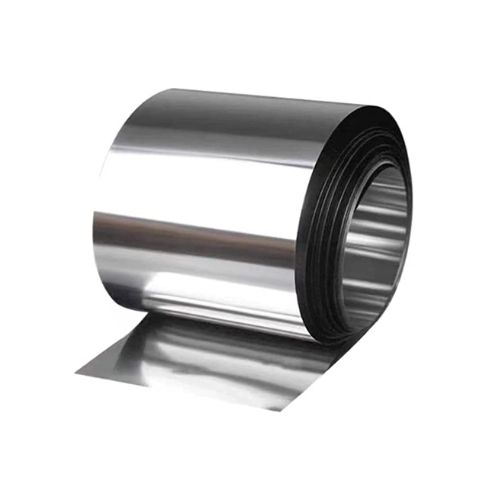

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

As the global demand for advanced and durable metal solutions accelerates, the stainless steel strip coil market is entering a new era of technological innovation and quality benchmarks. With the expansion of high-end manufacturing sectors—ranging from petrochemical, aerospace, automotive to precision electronics—the requirements for material strength, surface finish, and corrosion-resistant performance are tighter than ever.

Market Trends in Stainless Steel Strip Coil Industry

According to the 2023 report by World Steel Association, the global output of stainless steel strip coil exceeds 27 million tons and is projected to grow at 6% CAGR between 2024-2027 (source). China remains the largest producer, exporting over 4.5 million tons in 2023.

- Increasing demand for high quality stainless steel strip roll in electronics, automotive, and aerospace.

- Advancements in alloy composition and cold rolling precision for tighter gauge tolerance.

- Heightened focus on sustainability with recyclable, eco-friendly solutions.

Technical Overview: What Makes Stainless Steel Strip Coil Stand Out?

- Material Grade: Austenitic (304, 316/316L), Martensitic (420, 410), Ferritic (430), and Precipitation Hardened (17-4PH).

- Thickness Range: 0.05mm to 3.0mm

- Width Range: 3mm to 600mm

- Yield Strength: 200-2200 MPa (see technical comparison below)

- Hardness: HV 120-600 depending on annealing, tempering, and alloy

- Corrosion Resistance: Excellent in acidic/alkaline environments (ASTM A240 standard)

- Tolerance: ±0.01mm for precision stainless steel strip products

Manufacturing Process of Stainless Steel Strip Coil

- Melting & Primary Forming: Raw materials melted in electric arc furnace, cast into slab form.

- Hot Rolling: Slabs are hot-rolled into coils of initial thickness.

- Pickling: Acid bath removal of oxides and scale for surface purity.

- Cold Rolling: Multiple passes through precision rollers to reach target thickness and enhanced surface finish.

- Annealing & Tempering: Metal heat-treated for mechanical properties and microstructure tuning.

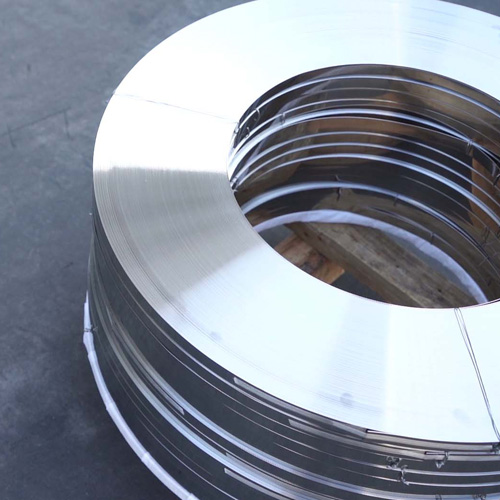

- Slitting & Edge Processing: Coils slit to desired width, deburred for application safety.

- Final Inspection (ISO/ANSI/FDA): Each stainless steel strip coil batch tested for thickness, hardness, tolerance, corrosion resistance.

Industry-Leading Product Specifications: Data & Comparison

To assist engineers and procurement professionals in accurate selection, the table below summarizes standard parameters of stainless steel strip coil types found in the global market:

| Grade | Condition | Thickness (mm) | Width (mm) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) | Standard |

|---|---|---|---|---|---|---|---|

| 304 (Austenitic) | Annealed | 0.05 - 3.0 | 5 - 600 | 210 - 400 | 35 - 60 | 170 - 210 | ASTM A240 |

| 316L (Austenitic) | Annealed | 0.08 - 2.5 | 10 - 420 | 200 - 390 | 30 - 58 | 160 - 200 | ISO 9445 |

| 430 (Ferritic) | Soft/Quarter Hard | 0.15 - 2.0 | 5 - 300 | 280 - 350 | 25 - 40 | 160 - 210 | ASTM A240 |

| 420/430 (Martensitic) | Hardened | 0.1 - 2.5 | 10 - 250 | 700 - 1300 | 8 - 16 | 220 - 600 | ANSI B32.8.1 |

| 17-4PH (PH) | H900 /H1150 | 0.2 - 1.6 | 8 - 180 | 900 - 1200 | 13 - 18 | 350 - 410 | ASTM A693 |

Product Benchmark: China Stainless Steel Coil Factory Export Stainless Steel Strip /belt/coils/plate

The China Stainless Steel Coil Factory Export Stainless Steel Strip /belt/coils/plate sets industry standards, offering:

- Raw Material Control: Sourcing from leading Chinese and international steel plants with traceable material records

- Process: Advanced vacuum smelting → HOT rolling (4/5-stand) → Continuous pickling → Ultra-fine cold rolling (20 Hi mill) → Bright annealing → Tension leveling & slitting → Ultrasonic batch testing

- Certifications: ISO 9001, ISO 14001, FDA, ASTM, ANSI, SGS, TUV Rhein standards adopted

- Surface: BA (Bright Annealed), 2B, Mirror, Hairline, No.4, customizable for decorative or engineering needs

- Thickness Tolerance: Up to ±0.005mm for precision grades

- Environment: ROHS-compliant, environmentally friendly oiling and passivation

- Automotive spring and exhaust assemblies

- Electronic components and precision shims

- Medical-grade clamps, brackets, and tools

- Chemical, petrochemical, and water supply systems

- Construction expansion joints

Visual Data: China Stainless Steel Coil Factory vs. Market Leaders

Comparative Analysis: Factory vs. Leading Suppliers

| Criteria | China Stainless Steel Coil Factory | Typical Major Supplier (Global) |

|---|---|---|

| Material Grades | 304/316L/201/420/430/17-4PH (full range) | 304/316/430 (mainly) |

| Thickness Tolerances | ±0.005mm (precision grade) | ±0.015mm |

| Surface Finishes | BA, 2B, Mirror, No.4, HL, Custom | BA, 2B, No.4 |

| Certification & Standards | ISO, ASTM, ANSI, FDA, CE, SGS, ROHS | ISO, ASTM |

| Lead Time | 7~25 days (typical volume) | 18~40 days |

| Custom Processing | CNC, laser, waterjet, edge polishing | Limited |

| Supply Capacity | 20,000+ tons/month | 8,000~12,000 tons/month |

Tailored Custom Solutions

Engineering projects often require non-standard specification or functional upgrades. The China Stainless Steel Coil Factory offers bespoke customization options:

- Thickness: From 0.03mm ultra-thin for microelectronics to 3.0mm for heavy-duty construction.

- Width: 8mm mini coils to 650mm wide jumbo rolls.

- Slitting: Razor-slit with edge roundness tolerance ≤ R0.10mm.

- Mechanical Properties: Spring temper, soft annealed, or custom-hardened per project need.

- Surface Finishes: Hairline, mirror, high-gloss, duplo for filter or decorative industries.

- Special Processing: CNC, stamping, laser cutting, subassembly, drill and slot, passivation.

- Packaging: Export-compliant seaworthy + anti-corrosion, barcode/traceability labels.

Application Case Studies & Customer Feedback

- Energy Plant Expansion (Middle East, 2023): Supplied 120 tons stainless steel strip coil for solar tracker spring systems. Lifespan improvements of 31% reported vs. previous supplier. All products passed onsite ASTM A480 corrosion and yield tests.

- Medical Device Manufacturer (Germany, 2022): Delivered custom-cut precision stainless steel strip (316L, 0.18mm, mirror) for manufacturing surgical clamps—zero rejection rate noted after FDA-compliant audit.

- Petrochemical Facility (Singapore, 2021): Switched to high quality stainless steel strip roll (430/2B, 1.1mm) in pipeline supports, achieving 8% cost-saving and 21% downtime reduction.

- Electronics (Korea, 2023): Thin gauge (0.07mm) delivered with ±0.005mm accuracy, praised for ease of auto-insertion in PCBA/SMT lines.

Professional FAQ: Key Terms & Technical Insights

- Q1: What is the primary material composition of a stainless steel strip coil?

- A: The most common alloys are 304 (Cr18Ni8), 316/316L (Cr17Ni12Mo2), 201, 420 and 430, featuring precise ratios of Chromium, Nickel, and sometimes Molybdenum to optimize corrosion resistance and mechanical strength.

- Q2: What thickness ranges are available for industrial applications?

- A: Industrial stainless steel strip coil is available from ultra-thin 0.03mm up to 3.0mm. For precision electronic and spring/high-tension applications, 0.05–0.20mm is typical.

- Q3: What is a "stainless spring steel strip" and what makes it unique?

- A: "Stainless spring steel strip" refers to high-carbon martensitic stainless steel (e.g., 420, 431) processed to high hardness (e.g., >500 HV) to provide resilience, impact resistance, and long-term energy storage in springs or flexing parts.

- Q4: How is the surface finish controlled?

- A: Factories use cold rolling, annealing, mechanical polishing, and chemical pickling to achieve controlled finishes such as 2B, BA, Mirror, No.4, or Hairline—each offering unique reflectivity, smoothness, and blandness for specific applications.

- Q5: What are global export certifications required?

- A: A reputable stainless steel strip factory will hold ISO 9001/14001, FDA registration for medical supply, ASTM/ANSI conformity for industrial, and SGS/ROHS for environmental safety. All export coils undergo third-party verification.

- Q6: How is width tolerance and flatness ensured?

- A: Width precision is guaranteed via programmable slitting with real-time feedback. Flatness is controlled by tension leveling, online laser guidance and continuous thickness measurement (±0.01mm typical).

- Q7: What inspection and testing do coils undergo before shipping?

- A: Each batch is subject to tensile, hardness, metallographic, surface (RA measurement), intergranular corrosion, and dimension checks. Many products meet EN 10204 3.1/3.2 and are supplied with full QA traceability reports.

Delivery Time, Warranty & Customer Support

- Delivery Lead Time: 7–25 days typical for mainstream grades (stainless steel strip coil); urgent and precision shipment services available.

- Warranty: 12~36 months material defect warranty, full replacement or refund for substandard batches; long-term corrosion performance warranty for industrial projects.

- After-Sales Support: 24/7 online technical support, global logistics tracking, free trial sample policy, and engineering guidance for installation or downstream processing.

- OEM/ODM Service: Custom markings, barcoding, assembly subparts, or surface treatment per customer IP/branding requirements.

- Payment Safety: Secure LC, T/T, escrow, LOA; SGS/TUV/BV third-party inspection permitted before shipment.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025