- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 09, 2024 16:46 Back to list

Worm Hose Clamps Manufacturer Specializing in Durable and Reliable Solutions for All Applications

Worm Hose Clamps The Unsung Heroes in Industrial Applications

In the world of industrial applications, the significance of seemingly minor components cannot be overstated. One such component that plays a vital role in the efficiency and reliability of various systems is the worm hose clamp. These unassuming devices are essential for securing hoses to fittings, preventing leaks, and maintaining the integrity of fluid transfer systems in countless industries. This article delves into the importance, manufacturing processes, and applications of worm hose clamps, as well as a look into factories that specialize in their production.

Understanding Worm Hose Clamps

A worm hose clamp is a type of adjustable metal fastener. It typically consists of a band made from stainless steel or other durable materials, a screw mechanism for tightening, and a housing that allows for secure attachment around hoses. The design includes a worm gear that allows for precise adjustments, making them ideal for various hose diameters and applications. Their usage spans across automotive systems, plumbing, irrigation, and even household appliances, showcasing their versatility.

One of the primary advantages of worm hose clamps is their ease of use. Maintenance technicians and engineers appreciate their straightforward installation—they can be tightened or loosened with a simple screwdriver or wrench. This user-friendly design not only saves time but also minimizes the potential for human error during crucial assembly processes.

Manufacturing Worm Hose Clamps

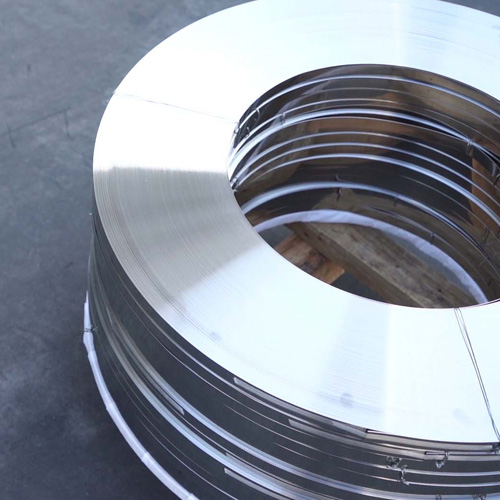

The production of worm hose clamps is a meticulous process that requires precision and quality control. Factories specializing in these components typically adopt a multi-step manufacturing approach. The first stage involves sourcing high-quality raw materials, such as stainless steel, which provides corrosion resistance and durability. After the materials are procured, they are cut into appropriate lengths to form the clamp bands.

Next, the manufacturing process moves toward shaping and assembling the clamps. This involves bending and welding the metal to create a loop, which is crucial for ensuring a secure fit around hoses. The spiral design of the wrenchable screw is then integrated, followed by a thorough inspection to maintain quality standards.

worm hose clamps factory

Advanced factories often utilize automation in their production lines to enhance efficiency and consistency. Automated machinery streamlines the cutting, bending, and assembly processes, consequently leading to increased output and reduced labor costs. Furthermore, quality assurance protocols are essential during production, with each batch being tested for tensile strength, structural integrity, and overall performance.

Applications Across Industries

Worm hose clamps find extensive application across various sectors. In the automotive industry, they are used to secure hoses in fuel systems and cooling systems. Their reliable hold ensures that engine performance remains optimal and mitigates the risk of leaks that could lead to catastrophic failures.

Additionally, in agriculture, these clamps are vital in irrigation systems for securing hoses, ensuring a continuous flow of water to crops. They also find their place in food and beverage processing, where hygiene and safety are paramount. Stainless steel worm hose clamps are often used to secure food-grade hoses, ensuring no contamination occurs during the transfer of liquid products.

Conclusion The Role of Factories in Supply and Innovation

As demand for worm hose clamps increases, factories dedicated to their production must focus not only on quality and efficiency but also on innovation. With the rapid advancement of materials technology and manufacturing processes, there is ample opportunity for enhancing the design and functionality of these clamps. By adopting sustainable practices and exploring alternative materials, manufacturers can not only meet industry demands but also contribute to environmental stewardship.

In conclusion, worm hose clamps may appear to be simple devices, but their impact on a wide range of industrial applications is profound. Through effective manufacturing and a commitment to quality, factories can ensure these unsung heroes continue to play their critical roles across various sectors.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025