- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Sep . 21, 2024 15:51 Back to list

vent hose clamp factory

The Importance of Quality in Vent Hose Clamp Manufacturing

In the world of industrial machinery and automotive applications, the significance of reliable and durable components cannot be overstated. Among these components, vent hose clamps play a crucial role in ensuring that hoses remain secure and efficient under varying conditions. As industries evolve and demand for high-quality products rises, vent hose clamp factories must focus on maintaining superior manufacturing standards.

The Importance of Quality in Vent Hose Clamp Manufacturing

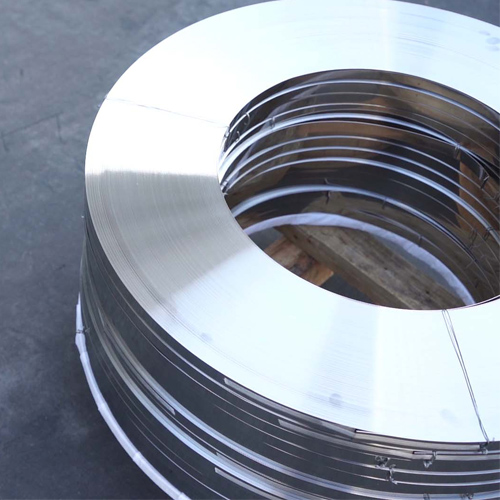

One of the key aspects of vent hose clamp manufacturing is the selection of materials. Factories often utilize materials like stainless steel, carbon steel, and polymers that offer strength and corrosion resistance. The choice of material can significantly affect the clamp’s longevity and functionality. High-quality raw materials lead to better products, which is why reputable manufacturers prioritize sourcing from trusted suppliers.

vent hose clamp factory

In addition to material quality, the manufacturing process itself plays an essential role in the final product's performance. Advanced technologies, such as robotic assembly and precision machining, can enhance production efficiency while ensuring consistency. Factories that invest in modern equipment and skilled labor are better positioned to produce clamps that meet rigorous industry standards.

Moreover, the significance of thorough testing cannot be overlooked. Vent hose clamps must undergo various tests, such as tensile strength, torque, and corrosion resistance evaluations. A reliable factory will implement a comprehensive testing protocol to ensure that each clamp can endure its intended application without failure. By employing such stringent testing measures, manufacturers not only enhance client trust but also reduce the risk of potential liabilities associated with product failures.

Furthermore, as environmental concerns grow, vent hose clamp factories are increasingly adopting sustainable practices. This includes implementing eco-friendly manufacturing processes and minimizing waste. Consumers are becoming more conscious of the environmental impact of their purchases, making sustainability an essential consideration in product development.

In summary, the manufacturing of vent hose clamps is a multifaceted process that requires attention to detail in material selection, production methods, and testing. As industries continue to demand high-quality components for their systems, factories that prioritize these aspects will thrive. Investing in quality not only enhances product performance but also fosters long-term customer relationships, a hallmark of success in the manufacturing arena.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.06,2025

-

High Quality Steel Midsole - EN Standard for Safety Shoes

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology|[Corrosion Resistance]&[Adjustable Design]

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

Large Stainless Steel Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance&Adjustable Design

NewsAug.05,2025