- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Aug . 12, 2024 12:56 Back to list

Top Manufacturers of 2 Percent Stainless Steel Hose Clamps for Industrial Applications and Projects

Understanding 2% Stainless Steel Hose Clamps Manufacturing Insights

Hose clamps are essential components in various industrial applications, providing reliable fastening solutions for hoses and pipes. Among the numerous materials used for manufacturing these clamps, 2% stainless steel has gained significant attention for its unique properties and advantages. This article delves into the manufacturing process, benefits, and applications of 2% stainless steel hose clamps, highlighting the importance of factories specializing in this niche.

What is 2% Stainless Steel?

2% stainless steel typically refers to a type of stainless steel that contains a small percentage of carbon, usually around 2%, along with chromium, nickel, and other alloying elements. These elements contribute to the steel’s resistance to corrosion, durability, and strength, making it a preferred material for various industrial applications, including hose clamps. The inclusion of a lower carbon percentage enhances the material's weldability and formability, allowing manufacturers to create precise and robust clamps.

Manufacturing Process

The production of 2% stainless steel hose clamps involves several meticulous steps

1. Material Sourcing Quality begins with sourcing high-grade 2% stainless steel. Factories often work closely with steel suppliers to ensure they receive materials that meet their stringent specifications.

2. Cutting and Shaping The stainless steel is then cut into flat strips, which are subsequently shaped into the desired dimensions for the clamps. This process typically involves mechanical shear cutting or laser cutting for precision.

3. Forming Once cut, the stainless steel strips undergo a forming process. This can include bending and rolling to achieve the requisite shape, ensuring that the clamps can fit around hoses snugly without damaging them.

4. Welding In some designs, the ends of the clamps need to be welded together. Factories utilize advanced welding techniques, such as TIG or MIG welding, to create a strong and uniform bond. This step is crucial for maintaining the integrity of the clamp during use.

5. Finishing After forming and welding, the clamps undergo a finishing process, which may include deburring, polishing, and applying protective coatings. The finishing enhances not only the appearance of the clamps but also their corrosion resistance.

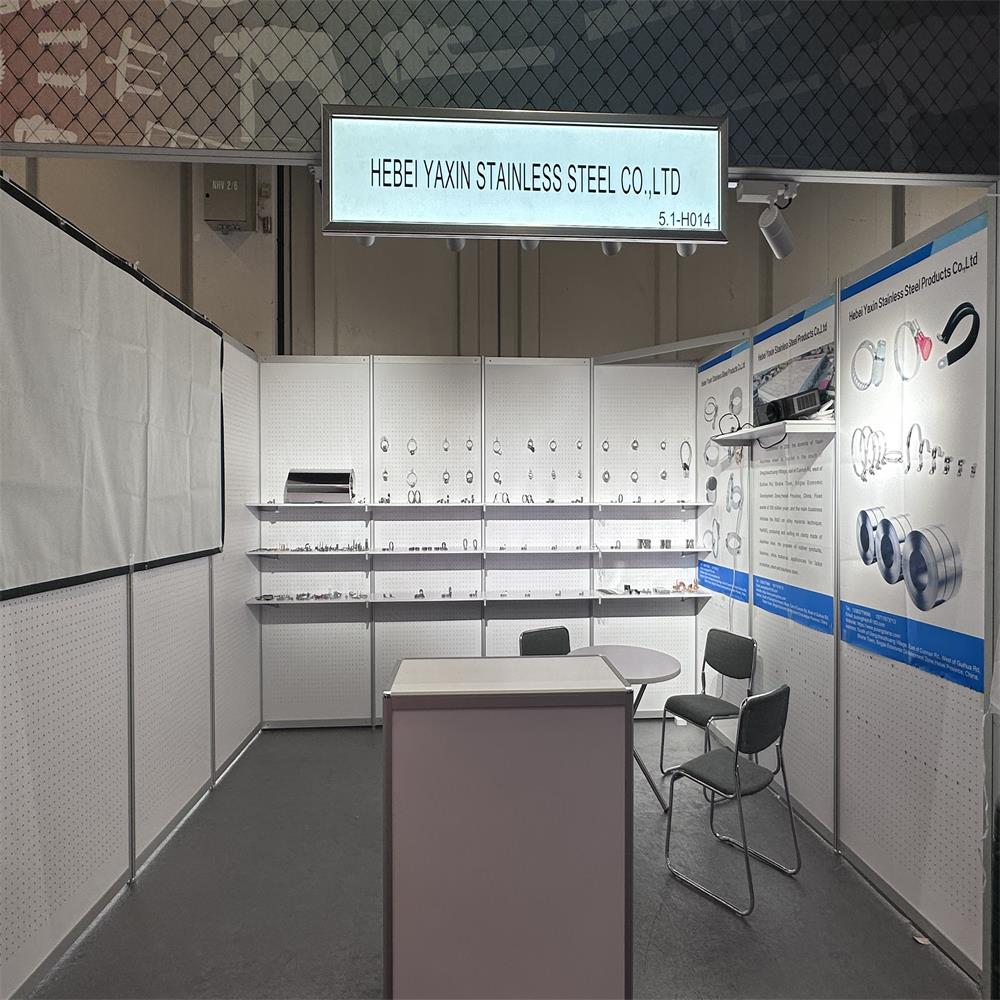

2 stainless steel hose clamps factories

6. Quality Control Before the clamps are packaged and shipped, rigorous quality control tests are conducted. This includes tensile strength testing, corrosion resistance assessments, and dimensional inspections to ensure each clamp meets the high standards expected by customers.

Benefits of 2% Stainless Steel Hose Clamps

1. Corrosion Resistance The chromium content in 2% stainless steel provides excellent resistance to rust and corrosion, which is essential for applications in harsh environments such as marine and industrial settings.

2. Durability These hose clamps can withstand high pressure and temperature variations, making them suitable for various applications, from automotive to aerospace.

3. Versatility They are available in different sizes and configurations, allowing for customization to meet specific requirements across diverse industries.

4. Cost-Effective While 2% stainless steel hoses offer high performance, they are relatively economical compared to other premium metals, providing a balance of cost and quality.

Applications

2% stainless steel hose clamps are utilized in numerous applications, including automotive fuel lines, irrigation systems, HVAC systems, and plumbing. Their reliability and performance make them a preferred choice for both commercial and residential use.

Conclusion

The manufacturing of 2% stainless steel hose clamps is a meticulous process that ensures the production of high-quality, durable fastening solutions. As industries continue to evolve, the demand for reliable hose clamps made from corrosion-resistant materials like 2% stainless steel will undoubtedly grow. Factories specializing in this niche play a crucial role in meeting these needs, contributing to the overall efficiency and safety of various operational processes across multiple sectors.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025