- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jan . 14, 2025 10:13 Back to list

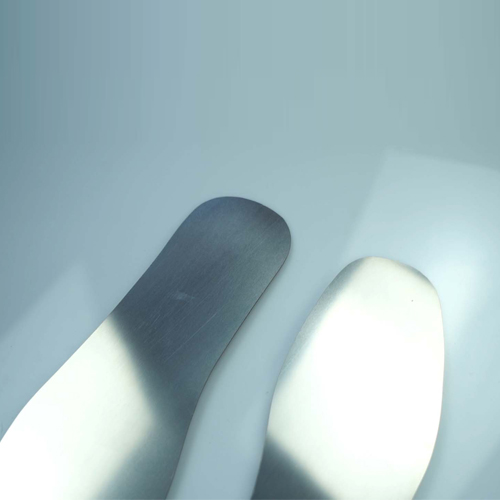

stainless hose clamp

When it comes to securing hoses in automotive, home, or industrial applications, the 1 spring hose clamp stands out as a reliable choice for experts who prioritize durability and ease of use. These clamps, often overlooked yet crucial, serve as a fundamental component in ensuring the safety and efficiency of fluid and gas transfer systems.

Authoritative manufacturing protocols are essential in producing these clamps. Leading manufacturers adhere to stringent quality control measures, ensuring each clamp meets or exceeds industry standards. Such commitment to excellence secures trust from end-users who rely on these clamps to maintain operational integrity. Brands that invest in R&D to refine the spring mechanism further enhance the clamp's reliability, reinforcing their standing as industry leaders. Trustworthiness, another crucial pillar, is evident through certifications and compliance with international standards. When sourcing spring hose clamps, look for manufacturers who provide clear documentation and testing results. This transparency allows consumers to make informed choices, fostering a sense of reliability and confidence in the product. Experts also advise regular inspection and replacement in high-stress environments to maintain peak performance. While their design is resilient, the rigors of heavy-duty applications can lead to wear over time. Thus, a proactive maintenance approach is recommended to ensure optimal functionality. In summary, the 1 spring hose clamp is much more than a simple tool; it embodies engineering precision and reliability. For professionals seeking solutions in fluid and gas handling, understanding the nuances of these clamps and trusting in their proven performance is essential. By leveraging the clamp's inherent properties and advancements in manufacturing, industries can achieve greater efficiency and safety, minimizing risks associated with fluid leaks. Selecting the right clamp, backed by authoritative expertise and trust, can significantly impact the success of complex systems, illustrating the clamp's pivotal role across diverse applications.

Authoritative manufacturing protocols are essential in producing these clamps. Leading manufacturers adhere to stringent quality control measures, ensuring each clamp meets or exceeds industry standards. Such commitment to excellence secures trust from end-users who rely on these clamps to maintain operational integrity. Brands that invest in R&D to refine the spring mechanism further enhance the clamp's reliability, reinforcing their standing as industry leaders. Trustworthiness, another crucial pillar, is evident through certifications and compliance with international standards. When sourcing spring hose clamps, look for manufacturers who provide clear documentation and testing results. This transparency allows consumers to make informed choices, fostering a sense of reliability and confidence in the product. Experts also advise regular inspection and replacement in high-stress environments to maintain peak performance. While their design is resilient, the rigors of heavy-duty applications can lead to wear over time. Thus, a proactive maintenance approach is recommended to ensure optimal functionality. In summary, the 1 spring hose clamp is much more than a simple tool; it embodies engineering precision and reliability. For professionals seeking solutions in fluid and gas handling, understanding the nuances of these clamps and trusting in their proven performance is essential. By leveraging the clamp's inherent properties and advancements in manufacturing, industries can achieve greater efficiency and safety, minimizing risks associated with fluid leaks. Selecting the right clamp, backed by authoritative expertise and trust, can significantly impact the success of complex systems, illustrating the clamp's pivotal role across diverse applications.

Share

Next:

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025