- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 11, 2024 04:40 Back to list

Versatile Square Hose Clamp for Secure Connections in Plumbing and Automotive Applications

Understanding the Square Hose Clamp A Comprehensive Guide

Hose clamps are ubiquitous in various industries, serving as essential components for creating secure connections in plumbing, automotive, and manufacturing applications. Among the multitude of designs and types available, the square hose clamp has emerged as a noteworthy option. This article delves into the characteristics, applications, benefits, and potential downsides of square hose clamps, providing a comprehensive overview for anyone interested in this specialized fastening solution.

What is a Square Hose Clamp?

A square hose clamp is a type of fastener designed to secure hoses and tubing to fittings and nozzles. Unlike traditional round clamps, square hose clamps feature a unique square design, which offers specific advantages in terms of grip and stability. The square shape helps distribute pressure more evenly across the surface of the hose, minimizing the risk of deformation or damage. Typically made from materials such as stainless steel or durable plastic, square hose clamps can withstand a variety of environmental conditions, including exposure to moisture, temperature fluctuations, and corrosive substances.

Applications of Square Hose Clamps

Square hose clamps are versatile and find applications in various fields

1. Automotive Industry In vehicles, square hose clamps are often used to secure hoses that transport fluids like coolant, oil, and fuel. Their robust design ensures that connections remain leak-proof under pressure and temperature changes.

2. Industrial Settings Manufacturing plants and factories utilize square hose clamps for pneumatic and hydraulic systems. These clamps ensure that hoses remain attached under high-pressure conditions, contributing to safe and efficient operations.

3. Plumbing In domestic and commercial plumbing, square hose clamps provide secure connections for water and drainage systems. They are particularly useful in applications where hoses need to be attached to rigid pipes or fittings.

Benefits of Square Hose Clamps

The square hose clamp design offers several benefits that make it an appealing choice for many applications

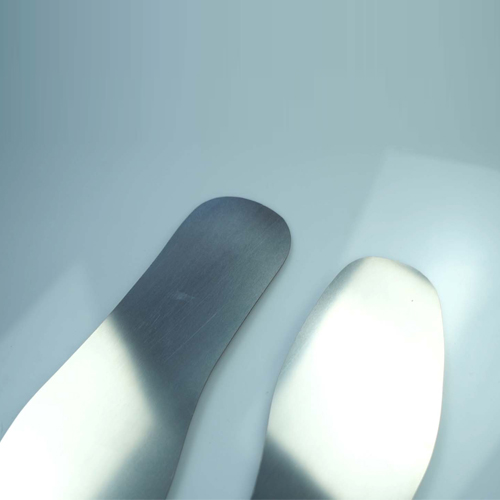

square hose clamp

- Enhanced Grip The square shape provides a larger surface area in contact with the hose, enhancing grip and reducing the likelihood of slippage.

- Even Pressure Distribution The design allows for more even distribution of pressure around the hose, which helps prevent damage and extends the lifespan of the hose and fittings.

- Ease of Installation Many square hose clamps are designed for easy installation, often featuring screw or latch mechanisms that can be tightened without specialized tools.

- Corrosion Resistance Depending on the material, square hose clamps can be highly resistant to rust and corrosion, making them suitable for both indoor and outdoor applications.

Potential Downsides

While square hose clamps offer numerous advantages, they may also pose some challenges

- Limited Size Options Depending on the manufacturer, there may be fewer size options available compared to traditional round clamps, which could limit their applicability in certain situations.

- Cost Square hose clamps may be slightly more expensive than standard hose clamps due to their specialized design and manufacturing processes.

- Compatibility Issues In some cases, the square shape may not fit as well in certain tight spaces as a round clamp would, making installation more difficult.

Conclusion

In summary, square hose clamps represent a specialized fastening solution that offers distinct advantages for various applications across multiple industries. Their ability to provide an enhanced grip, even pressure distribution, and resistance to environmental factors makes them an attractive option for those seeking reliable hose connections. While they may come with some limitations regarding size options and cost, the benefits often outweigh the downsides, particularly in high-stakes settings such as automotive and industrial applications. As technology continues to evolve, the design and manufacturing of square hose clamps will likely become even more refined, ensuring that they remain a vital tool in the modern toolkit for engineers and technicians alike. Understanding the specific requirements of your application can help you choose the right hose clamp—square or otherwise—for optimal performance.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.06,2025

-

High Quality Steel Midsole - EN Standard for Safety Shoes

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology|[Corrosion Resistance]&[Adjustable Design]

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

Large Stainless Steel Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance&Adjustable Design

NewsAug.05,2025