- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 20, 2024 18:30 Back to list

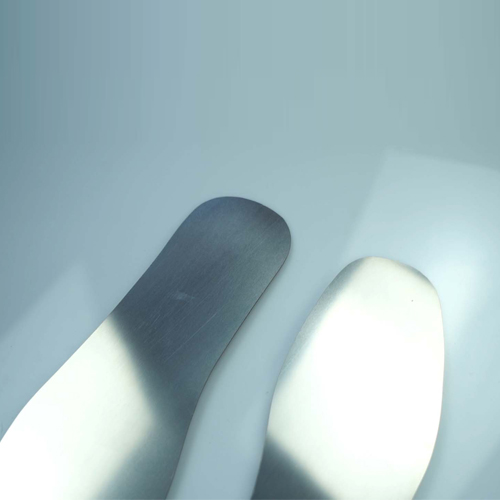

smooth band hose clamps

The Importance of Smooth Band Hose Clamps in Industrial Applications

Hose clamps are a fundamental component in a variety of industrial, automotive, and domestic applications. Among the various types available, smooth band hose clamps stand out due to their unique design and efficiency. These clamps are essential for securing hoses and tubing in place, preventing leaks and ensuring optimal performance in different systems.

What Are Smooth Band Hose Clamps?

Smooth band hose clamps are characterized by their construction, which features a smooth, continuous band that is designed to encircle a hose without cutting into it. This prevents damage to the hose, which is a common problem with traditional hose clamps that have serrated edges. The smooth band provides even pressure distribution around the hose, allowing for a secure fit without compromising the integrity of the material.

Applications

Smooth band hose clamps are versatile and can be found in numerous applications across various industries. Some of their common uses include

1. Automotive Industry In automobiles, these clamps secure coolant and fuel hoses, ensuring that fluids do not leak and systems operate efficiently. Given the high vibrations and temperatures in engines, a reliable clamp is crucial.

2. Aerospace In the aerospace industry, components must endure extreme conditions, including high altitudes and varying temperatures. Smooth band hose clamps provide the necessary reliability for securing vital systems in aircraft.

3. Marine Applications In marine environments, preventing leaks is paramount to ensure safety and performance. Smooth band hose clamps resist corrosion due to their materials, making them ideal for use in boats and other watercraft.

smooth band hose clamps

Advantages of Smooth Band Hose Clamps

1. Gentle on Hoses The smooth surface of the band minimizes the risk of damage to hoses, which can happen with serrated clamps that grip too tightly or unevenly.

2. Corrosion Resistance Many smooth band hose clamps are made from materials such as stainless steel, which not only offer strength but also resist rust and corrosion. This feature extends the clamps' lifespan, especially in humid or marine environments.

3. Easy Installation Most smooth band hose clamps come with simple mechanisms (like a screw or easy-to-tighten design) that make them user-friendly. They can be installed quickly with minimal tools, making them a favorite among technicians and DIY enthusiasts alike.

4. Consistent Pressure The design allows for better uniform pressure across the hose, which is crucial for preventing leaks and maintaining system efficiency. This uniformity helps in managing fluctuations that may occur in pressure within the hoses.

5. Size Variety Smooth band hose clamps are available in a range of sizes and widths, making them adaptable for various applications. This versatility allows businesses and consumers to find the correct clamp for their specific needs.

Conclusion

In summary, smooth band hose clamps are an essential component in many fields, offering numerous benefits over traditional hose clamps. Their ability to provide secure, reliable connections without damaging the hoses they secure makes them invaluable in maintaining system integrity across applications. As industries continue to evolve, the demand for reliable components like smooth band hose clamps will undoubtedly grow. Whether in automotive, aerospace, marine, or even household applications, these clamps prove their worth through durability and performance, ensuring that operations run smoothly and efficiently. For anyone involved in installations that require secure connections, the choice of smooth band hose clamps should be at the forefront of their considerations.

-

Quality 201 Stainless Steel Strip | Durable & Cost-Effective

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025