- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 18, 2024 01:42 Back to list

rotor clip hose clamps factories

The Importance of Rotor Clip Hose Clamps Factories and Manufacturing Insights

In the industrial landscape, hose clamps play a crucial role in a multitude of applications, serving to secure and stabilize hoses, tubes, and pipes. Among the various manufacturers in the market, Rotor Clip stands out for its specialized hose clamp solutions, renowned for quality, reliability, and precision engineering. This article will delve into the significance of Rotor Clip hose clamps, explore the manufacturing processes involved, and highlight the pivotal role of factories in ensuring product excellence.

Understanding Hose Clamps

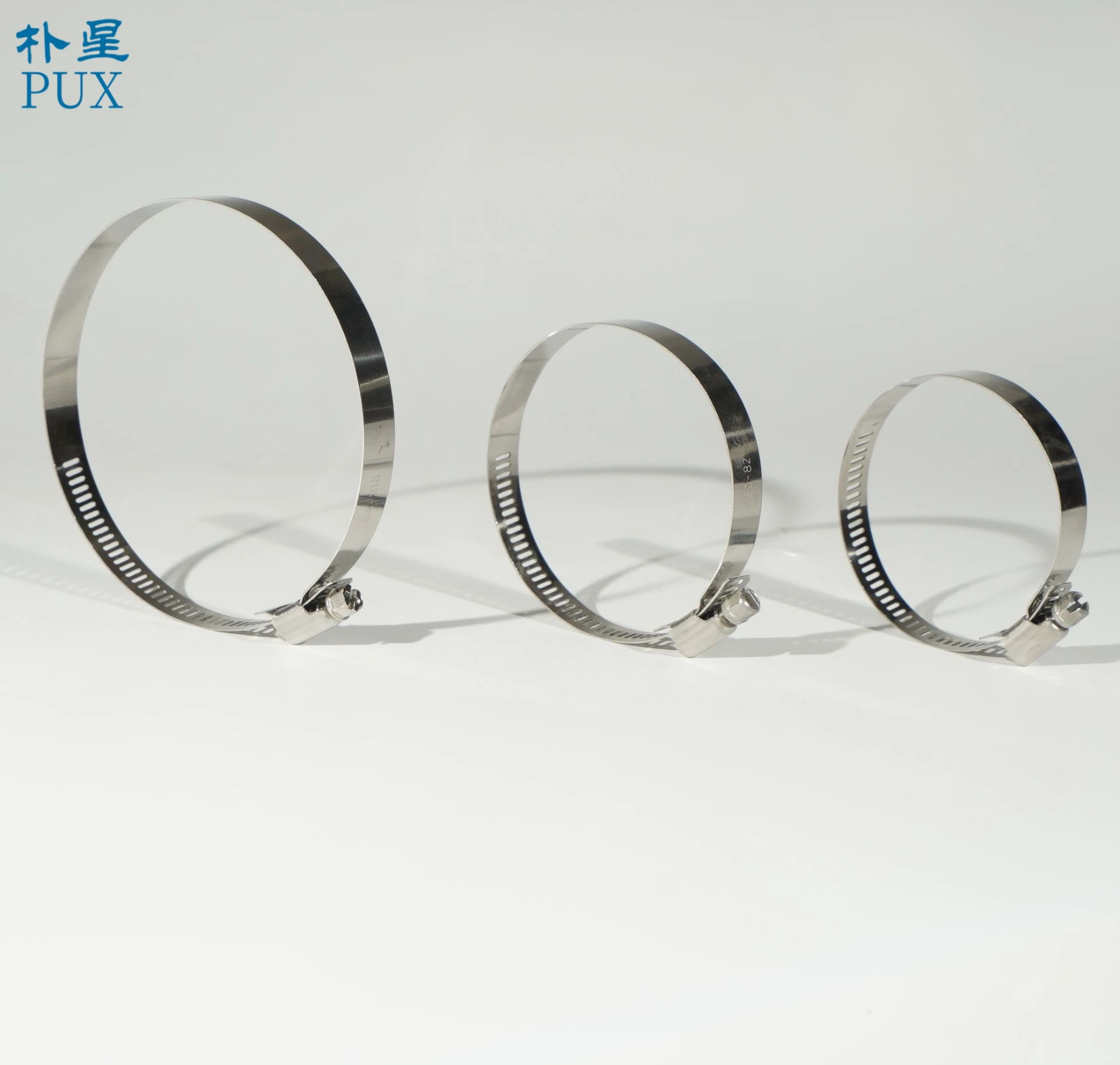

Hose clamps, also termed as hose clips, are widely utilized in automotive, plumbing, and HVAC applications. They secure hoses or tubing over fittings to prevent leakage and ensure that fluids are contained within the system. The integrity of these assemblies is critical; even a slight failure could lead to significant disruptions, leaks, or costly repairs. This is where high-quality manufacturing comes into play, making Rotor Clip hose clamps a dependable choice for various industries.

Rotor Clip A Leader in Hose Clamp Manufacturing

Rotor Clip has established itself as a leading manufacturer of hose clamps, among other products. With decades of experience, the company focuses on providing high-quality solutions that cater to diverse industrial needs. Their hose clamps come in various designs, including worm gear, spring, and constant torque clamps, each designed for specific applications and requirements. This extensive range allows customers to select the most appropriate clamp for their needs, enhancing efficiency and performance.

Manufacturing Processes

The manufacturing of Rotor Clip hose clamps involves meticulous attention to detail to ensure the highest standards of quality. The process begins with the selection of superior raw materials, often stainless steel or carbon steel, which are known for their strength and resistance to corrosion.

1. Design and Prototyping Product development starts with designing clamps that meet the specific needs of clients. Engineers utilize advanced CAD software to create precise models, which are then prototyped for testing and validation.

2. Stamping and Forming Once designs are finalized, sheets of metal are subjected to stamping and forming processes. This step involves cutting and shaping the material into the required clamp designs using high-precision machinery. Rotor Clip utilizes state-of-the-art automated equipment to maintain consistency and accuracy during this phase.

rotor clip hose clamps factories

3. Heat Treatment After forming, the clamps may undergo heat treatment to enhance their strength and durability. This process ensures that the final product can withstand operating pressures and environmental conditions.

4. Surface Finishing The surface of the clamps is treated to provide corrosion resistance and aesthetic appeal. Various coatings can be applied depending on the customer's requirements, ensuring that the clamps can endure harsh operating environments.

5. Quality Control Rotor Clip places a strong emphasis on quality assurance. Every clamp undergoes rigorous testing to ensure they meet stringent industry standards. This involves checking for tensile strength, dimensional accuracy, and durability under stress.

6. Packaging and Distribution Finally, the clamps are carefully packaged to prevent damage during transportation. Effective logistics ensure that products reach customers in a timely manner, ready for installation in their respective applications.

The Role of Factories in Production

Factories like Rotor Clip are pivotal in the production of hose clamps. They must integrate cutting-edge technology with skilled labor to produce reliable and efficient products. Moreover, the factories constantly innovate and improve manufacturing processes, ensuring scalability and sustainability in production.

The importance of factories goes beyond mere manufacturing. They drive local economies, create jobs, and foster community development. Rotor Clip, as a factory, demonstrates this by investing in workforce training and community initiatives, thereby contributing positively to the society in which it operates.

Conclusion

In summary, Rotor Clip hose clamps represent high-quality engineering and reliable performance in the industrial sector. The meticulous manufacturing processes employed by factories not only ensure product excellence but also play a crucial role in various applications where safety and efficiency are paramount. As industries continue to evolve, the demand for advanced hose clamp solutions will only grow, solidifying Rotor Clip's position as a leader in the market.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025