- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 05, 2024 10:35 Back to list

precision brand hose clamps factories

Precision Brand Hose Clamps A Comprehensive Overview of Factories and Production

Hose clamps play a crucial role in various industries by securing hoses to fittings and preventing leaks. Among the myriad of choices available in the market, Precision Brand Hose Clamps stand out for their durability and reliability. This article delves into the factories behind Precision Brand Hose Clamps, examining their production processes, quality control measures, and the overall impact on various applications.

The Importance of Hose Clamps

Hose clamps are essential components used in automotive, industrial, and household applications. They offer a simple but critical function ensuring that hoses remain securely attached to mechanical fittings under pressure. Ineffective clamps can lead to leaks, resulting in equipment failure, safety hazards, or costly repairs. Therefore, the importance of high-quality hose clamps cannot be overstated, and Precision Brand has earned a reputation for providing exemplary products.

Manufacturing Facilities

Precision Brand Hose Clamps are manufactured in state-of-the-art facilities equipped with advanced technology and machinery. The factories are strategically located to optimize distribution and supply chain logistics. These modern manufacturing plants employ lean production techniques to maximize efficiency while minimizing waste.

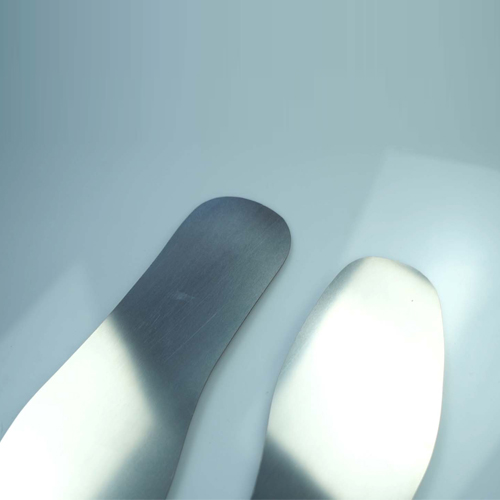

The process starts with the careful selection of raw materials, primarily stainless steel and other high-strength alloys known for their resistance to corrosion and wear. The factories ensure that every piece of material is thoroughly vetted before production begins, setting the stage for high-quality end products.

Production Process

The manufacturing process begins with wire forming, where stainless steel wire is shaped into various configurations depending on the type of clamp being produced. For instance, worm gear clamps, which are widely used, require different specifications than spring clamps or t-bolt clamps.

Once the wire is shaped, it undergoes a series of processes, including cutting, bending, and assembly. Computer Numerical Control (CNC) machines are frequently employed to ensure precision and consistency in the dimensions of each component. Innovative technologies mean that production is not only faster but also allows for customization, catering to clients with specific needs.

precision brand hose clamps factories

Quality Control

Quality assurance is paramount in the production of hose clamps. Precision Brand factories implement rigorous quality control measures at every stage of manufacturing. This includes checking the tensile strength of materials, ensuring that the clamps meet standardized dimensions, and conducting leak tests under simulated conditions.

Moreover, each batch of hose clamps is subjected to final inspections before packaging. Any product that does not meet the stringent standards is discarded or sent back for rework. This meticulous approach guarantees that customers receive reliable and robust products that can withstand the demands of their intended applications.

Environmental Considerations

As industries increasingly focus on sustainability, Precision Brand is committed to reducing its environmental footprint. The factories are designed to minimize waste through efficient resource management and recycling initiatives. Furthermore, the company invests in energy-efficient technologies to reduce power consumption during the manufacturing process.

By emphasizing eco-friendly practices, Precision Brand not only enhances its operational efficiency but also contributes positively to the environment, appealing to customers who value sustainability.

Conclusion

Precision Brand Hose Clamps are a testament to high-quality manufacturing, driven by advanced technologies and a commitment to impeccable quality control. The factories producing these clamps play a pivotal role in ensuring that diverse industries can rely on them for safety and performance.

As the landscape of manufacturing continues to evolve, Precision Brand remains at the forefront, dedicated to innovation and excellence in hose clamp production. By prioritizing quality, efficiency, and sustainability, the factories underpinning these products ensure that Precision Brand Hose Clamps will continue to serve as a trusted choice for securing hoses in various applications for years to come.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025