- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Sep . 10, 2024 11:55 Back to list

High-Quality Pinch Hose Clamps Manufacturer | Durable & Reliable Solutions

The Evolution and Significance of Pinch Hose Clamps in Modern Manufacturing

In the realm of industrial manufacturing, the efficient management of various systems is crucial. One of the often-overlooked components that play an essential role in fluid transfer systems is the pinch hose clamp. Though they may seem like simple tools, pinch hose clamps are pivotal in ensuring the integrity and reliability of fluid systems across multiple industries.

Understanding Pinch Hose Clamps

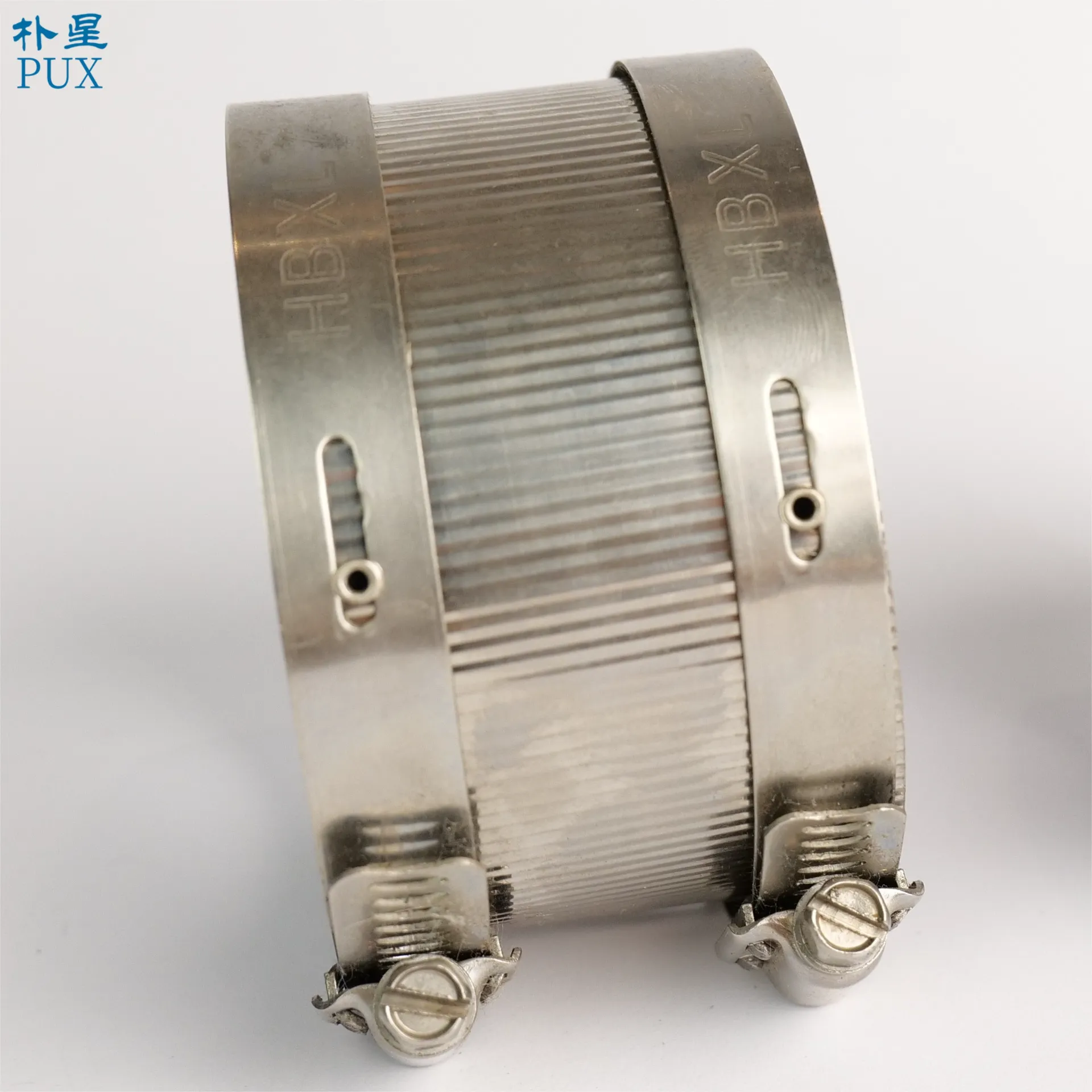

Pinch hose clamps are designed to secure hoses and prevent leaks in applications where traditional hose clamps may not be suitable. Unlike standard clamps that utilize a tightening mechanism, pinch clamps effectively compress the hose material to create a tight seal. This unique feature makes them particularly useful in applications where quick adjustments and removals are necessary without damaging the hose.

These clamps are typically made from durable materials such as stainless steel, which provides corrosion resistance and long-lasting performance. Their design allows them to adapt to various hose diameters and types, making them versatile tools in both residential and industrial settings.

Applications Across Industries

The applications of pinch hose clamps are widespread. In the automotive industry, they are used in coolant and fuel systems to ensure leak-free operation. The medical field also utilizes these clamps in various equipment, such as IV drip systems, where hygiene and reliability are paramount. Moreover, in agricultural applications, pinch hose clamps secure hoses for irrigation systems, ensuring water is delivered efficiently to crops.

pinch hose clamp factory

The demand for pinch hose clamps has surged in recent years, driven by advancements in technology and a growing emphasis on safety and efficiency. Manufacturers across the globe, particularly those focused on high-quality production, have started to recognize the importance of incorporating pinch clamps in their operations.

Quality Control and Manufacturing Process

The manufacturing of pinch hose clamps requires careful attention to detail and adherence to strict quality control measures. Leading factories employ cutting-edge technology and skilled workers to produce clamps that meet international standards. The process generally begins with raw materials being meticulously chosen to ensure durability and performance.

After manufacturing, each clamp undergoes a rigorous testing phase, where they are subjected to various stress tests to ensure they can withstand high-pressure environments without failure. Factories that prioritize transparency and sustainability are gaining traction in the market, as consumers increasingly seek products from companies that value ethical production practices.

The Future of Pinch Hose Clamps

As industries evolve, so too will the pinch hose clamp. Innovations such as smart materials that can self-adjust based on pressure changes are already being explored. The growth of automation and the Internet of Things (IoT) in manufacturing processes will also likely enhance the applications for pinch hose clamps, ensuring they remain a vital component in fluid management systems.

In conclusion, pinch hose clamps are more than just simple tools; they are a testament to the advancements in manufacturing and engineering. Understanding their significance and continuously improving their designs will be essential for industries aiming for higher efficiency and reliability in fluid systems. As technology progresses, we can expect the pinch hose clamp to remain an indispensable part of our industrial landscape.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025