- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Mar . 03, 2025 13:29 Back to list

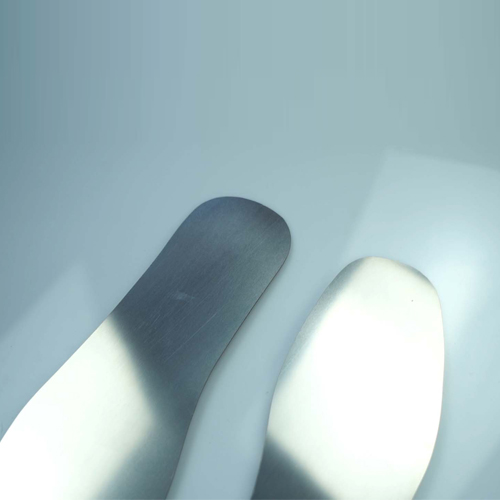

hose clamp with rubber insert

In the diverse realm of hardware accessories and fastening solutions, the hose clamp with a rubber insert has emerged as a vital component offering distinct advantages in various applications. While it may seem like a simple device, this tool stands as a testament to engineering advancements that focus on durability, efficiency, and adaptability. Here's a deep dive into why this particular clamp is essential and how it excels compared to its counterparts.

With respect to authoritativeness and trustworthiness, numerous studies and case tests document the enhanced performance of clamps with rubber inserts compared to traditional models. Industry leaders and manufacturers have prioritized these clamps in their product lines, evidencing their commitment to quality and customer satisfaction. Their trust in such components translates to wider industry acceptance and reliability. Longevity and resilience are also paramount when evaluating the economic viability of a product. The incorporation of rubber into hose clamps not only enhances functionality but also offers a cost-effective solution over time. By reducing the frequency of replacements and maintaining the integrity of the system being clamped, businesses save resources, contributing to greener practices and operational efficiency. It's worth noting that innovation within this product category continues to advance. Manufacturers are exploring various rubber materials, such as EPDM, nitrile, and silicone, to cater to specialized needs, ranging from thermal resistance in high-temperature environments to chemical compatibility in corrosive settings. These developments ensure that the hose clamps with rubber inserts remain at the cutting edge of fastening solutions, addressing contemporary challenges with innovative approaches. In conclusion, the hose clamp with a rubber insert is not merely an accessory but a critical element in modern mechanical and industrial applications. Its unique construction offers myriad benefits, from enhanced durability and sealing to noise reduction and ease of use. Trusted by experts and backed by authoritative sources, these clamps represent a convergence of practical engineering and innovative design, ensuring reliability in even the most demanding environments. Businesses and professionals prioritizing efficiency, safety, and quality would do well to consider leveraging the advantages offered by these remarkable components.

With respect to authoritativeness and trustworthiness, numerous studies and case tests document the enhanced performance of clamps with rubber inserts compared to traditional models. Industry leaders and manufacturers have prioritized these clamps in their product lines, evidencing their commitment to quality and customer satisfaction. Their trust in such components translates to wider industry acceptance and reliability. Longevity and resilience are also paramount when evaluating the economic viability of a product. The incorporation of rubber into hose clamps not only enhances functionality but also offers a cost-effective solution over time. By reducing the frequency of replacements and maintaining the integrity of the system being clamped, businesses save resources, contributing to greener practices and operational efficiency. It's worth noting that innovation within this product category continues to advance. Manufacturers are exploring various rubber materials, such as EPDM, nitrile, and silicone, to cater to specialized needs, ranging from thermal resistance in high-temperature environments to chemical compatibility in corrosive settings. These developments ensure that the hose clamps with rubber inserts remain at the cutting edge of fastening solutions, addressing contemporary challenges with innovative approaches. In conclusion, the hose clamp with a rubber insert is not merely an accessory but a critical element in modern mechanical and industrial applications. Its unique construction offers myriad benefits, from enhanced durability and sealing to noise reduction and ease of use. Trusted by experts and backed by authoritative sources, these clamps represent a convergence of practical engineering and innovative design, ensuring reliability in even the most demanding environments. Businesses and professionals prioritizing efficiency, safety, and quality would do well to consider leveraging the advantages offered by these remarkable components.

Share

Next:

Latest news

-

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025