- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 15, 2024 10:33 Back to list

hose clamp with mounting bolt manufacturers

Hose Clamps with Mounting Bolt Manufacturers and Their Importance

Hose clamps are essential components in various industries, providing a reliable means of securing hoses to fittings. Among the numerous types available, hose clamps with mounting bolts stand out due to their enhanced functionality and stability, especially in applications requiring robust and persistent attachment under challenging conditions. This article delves into the manufacturing landscape of hose clamps with mounting bolts, highlighting their importance, applications, and what to consider when choosing a manufacturer.

Understanding Hose Clamps with Mounting Bolts

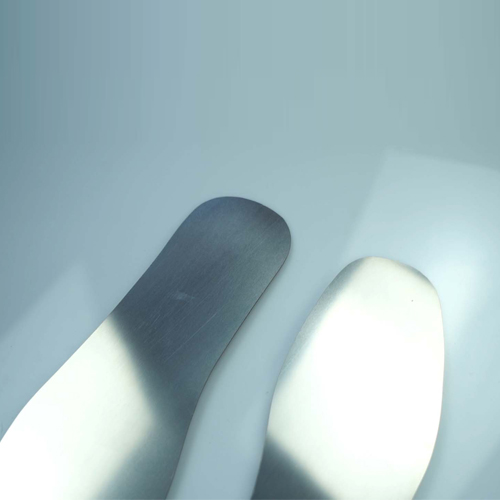

A hose clamp with a mounting bolt typically consists of a circular band that is tightened around a hose, featuring a bolt mechanism for secure attachment. This design allows for the clamp to be mounted directly onto a surface or chassis, providing a stable and fixed point for the hose. The incorporation of a mounting bolt adds an extra layer of security, preventing the clamp from loosening over time due to vibrations or thermal expansion that can occur in various industrial settings.

Key Applications

These specialized hose clamps are widely used across many sectors, including automotive, aerospace, plumbing, and manufacturing. In the automotive industry, for instance, they secure coolant hoses and fuel lines, ensuring proper fluid flow and minimizing the risk of leaks. In the aerospace sector, where safety and reliability are paramount, hose clamps with mounting bolts play a critical role in ensuring that hydraulic lines are securely fastened. Additionally, in plumbing applications, they are indispensable for securing pipes and hoses in both residential and commercial systems.

Choosing the Right Manufacturer

When selecting a manufacturer for hose clamps with mounting bolts, several key factors should be considered

hose clamp with mounting bolt manufacturers

1. Material Quality The durability and effectiveness of hose clamps heavily depend on the materials used. Manufacturers should provide clamps made from high-quality stainless steel, zinc-plated steel, or other corrosion-resistant materials, especially for applications exposed to harsh environments.

2. Manufacturing Standards It is crucial to choose manufacturers that adhere to strict manufacturing standards such as ISO 9001. Certifications indicate a commitment to quality control and assurance, ensuring the products meet necessary safety and performance requirements.

3. Customization Options Different applications often require specific sizes, designs, or performance capabilities. A reputable manufacturer will offer customization options, allowing businesses to procure hose clamps tailored to their unique needs.

4. Technical Support and Expertise The presence of knowledgeable support staff can greatly benefit customers. Manufacturers should provide technical assistance, helping customers select the right products and offering solutions for complex projects.

5. Reputation and Experience Researching the manufacturer's reputation in the market can provide insights into the quality of their products. Established manufacturers with a proven track record are often more reliable than newer companies.

Conclusion

Hose clamps with mounting bolts are integral components in a multitude of applications, offering secure fastening solutions that enhance safety and efficiency. As industries continue to advance, the need for high-quality, durable hose clamps will only increase. Therefore, selecting the right manufacturer is crucial for ensuring long-term performance and reliability. By considering material quality, manufacturing standards, customization options, technical support, and the manufacturer’s reputation, businesses can make informed decisions that will lead to successful outcomes in their operations. Investing in proper hose clamp solutions ultimately contributes to the overall quality and safety of systems across various industries.

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance,High Torque

NewsAug.17,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistant High Torque Adjustable

NewsAug.17,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.17,2025

-

Durable Stainless Steel Hose Clips & Clamps for Secure Fittings

NewsAug.17,2025