- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 16, 2024 13:53 Back to list

Hose Clamp Ring Manufacturer Innovative Solutions for Reliable Pipe Connections

The Hose Clamp Ring Factory Driving Innovation and Quality

In the intricate world of manufacturing, hose clamp ring factories play a crucial role in providing essential components that ensure the functionality and reliability of various systems, including automotive, plumbing, and industrial machinery. These factories are specialized facilities dedicated to the production of hose clamps—devices designed to secure hoses to fittings, preventing leakage and ensuring a tight seal. This article explores the importance of hose clamp ring factories, their manufacturing processes, and the innovations shaping the industry.

The Importance of Hose Clamps

Hose clamps are ubiquitous in countless applications. From keeping coolant in automotive systems to securing fuel lines and water hoses, they are integral to many mechanical and plumbing systems. A high-quality hose clamp provides the necessary pressure to hold hoses in place while being resistant to environmental stresses, such as temperature fluctuations and corrosive substances. This reliability is essential for the safety and efficiency of various systems, making the role of hose clamp ring factories indispensable.

Manufacturing Processes

The production of hose clamps involves several key steps, starting with material selection. Most hose clamps are made from stainless steel, carbon steel, or plastic, chosen for their durability and resistance to corrosion. Once the materials are sourced, they undergo processes such as cutting, bending, and forming. Advanced machinery is employed to ensure precision and consistency in each clamp's dimensions.

The next critical step is the assembly of components. Hose clamps may include various features, such as adjustable screws or locking mechanisms, which require skilled operators and automated systems to ensure that each product meets quality standards. Rigorous quality control measures are enforced throughout the manufacturing process, including stress tests and inspections, to guarantee that the final product performs under the demanding conditions it is designed for.

Innovations in Hose Clamp Manufacturing

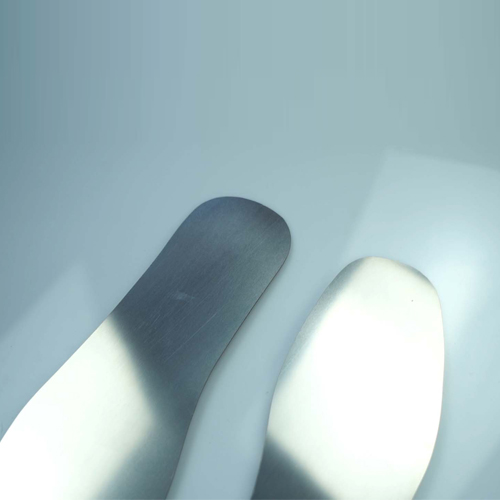

hose clamp ring factory

The hose clamp industry has not remained static; it has evolved with advancements in technology and materials science. Modern hose clamp ring factories are increasingly adopting automated production lines that enhance efficiency while reducing human error. Robotics and computer numerical control (CNC) machines are utilized to streamline the manufacturing process, resulting in faster turnaround times and lower production costs.

Moreover, the trend towards sustainability has influenced the industry, with many factories exploring eco-friendly materials and practices. Innovations such as biodegradable plastics and recycled materials are being integrated into production, aligning with global efforts to reduce environmental impact. Additionally, improvements in coating techniques have led to enhanced corrosion resistance, prolonging the life of hose clamps and reducing the need for replacements.

The Future of Hose Clamp Ring Factories

As industries continue to evolve, the demand for high-performance hose clamps will only increase. The automotive sector, with the rise of electric vehicles and advanced technology, presents new challenges and opportunities for hose clamp manufacturers. Factories that can adapt to these changes—by innovating their designs and improving their manufacturing processes—will be well-positioned for success.

Furthermore, as global markets become more interconnected, hose clamp ring factories must also focus on quality and compliance with international standards. This ensures that their products can compete on the global stage, meeting the diverse needs of customers around the world.

Conclusion

Hose clamp ring factories are vital players in the manufacturing landscape, producing components that ensure the safety and efficiency of numerous systems. Through a commitment to quality, innovation, and sustainability, these factories are poised to meet the evolving demands of modern industries. As technology advances and global needs change, the hose clamp industry will continue to adapt, providing solutions that are critical to the functioning of countless applications.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025