- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 19, 2025 11:33 Back to list

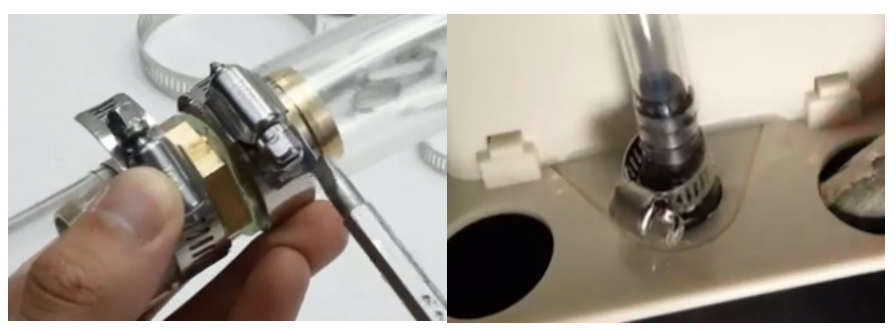

High Quality German Type Clamps Clips Stainless Steel Pipe Hose Clamp

When dealing with hose clamp issues, particularly when they refuse to tighten, the solution requires an understanding that goes beyond just turning a screw or bolt. A hose clamp that won't tighten can cause leakage, inefficiency, or even equipment failure in both residential and industrial settings. Here, we will delve into the reasons why hose clamps might not tighten and provide expert advice on how to address these challenges, ensuring a seal that is both reliable and durable.

Installation technique is another critical factor influencing whether a hose clamp functions correctly. The tightening mechanism, typically a screw, must be turned just enough; over-tightening can damage both the clamp and hose, while under-tightening fails to provide a secure connection. In some cases, lubricating the threads of the clamp screw can promote a smoother tightening process without the risk of seizing or stripping. Environmental factors are often overlooked but can significantly impact clamp performance. Temperature fluctuations can cause materials to expand and contract, which may compromise the seal integrity. For applications subject to extreme temperature variations, consider using clamps designed for those conditions, such as those featuring a silicone lining, which maintains elasticity better than standard rubber under temperature shifts. For professionals in need of guaranteed tight seals under high-pressure or high-temperature conditions, consulting with a hose specialist can be highly advantageous. They can provide recommendations on the best type of hose and clamp combinations suitable for specific uses. High-stress applications might benefit from heavy-duty clamps designed to withstand extreme conditions without failure. Ultimately, the key to ensuring a hose clamp tightens correctly lies in a blend of selecting the right product, proper sizing and fitting, ongoing maintenance, and considering the environmental contexts in which the clamp must perform. By doing so, one can achieve not just a tight seal, but also enhance the longevity and reliability of the entire system, thereby avoiding costly downtime and repairs. By understanding and addressing these factors, individuals and companies can maintain operational efficiency and uphold the standards of safety and reliability that modern applications demand. The emphasis on quality materials, appropriate sizing, and correct installation cannot be overstated when dealing with the seemingly simple but critically important hose clamp.

Installation technique is another critical factor influencing whether a hose clamp functions correctly. The tightening mechanism, typically a screw, must be turned just enough; over-tightening can damage both the clamp and hose, while under-tightening fails to provide a secure connection. In some cases, lubricating the threads of the clamp screw can promote a smoother tightening process without the risk of seizing or stripping. Environmental factors are often overlooked but can significantly impact clamp performance. Temperature fluctuations can cause materials to expand and contract, which may compromise the seal integrity. For applications subject to extreme temperature variations, consider using clamps designed for those conditions, such as those featuring a silicone lining, which maintains elasticity better than standard rubber under temperature shifts. For professionals in need of guaranteed tight seals under high-pressure or high-temperature conditions, consulting with a hose specialist can be highly advantageous. They can provide recommendations on the best type of hose and clamp combinations suitable for specific uses. High-stress applications might benefit from heavy-duty clamps designed to withstand extreme conditions without failure. Ultimately, the key to ensuring a hose clamp tightens correctly lies in a blend of selecting the right product, proper sizing and fitting, ongoing maintenance, and considering the environmental contexts in which the clamp must perform. By doing so, one can achieve not just a tight seal, but also enhance the longevity and reliability of the entire system, thereby avoiding costly downtime and repairs. By understanding and addressing these factors, individuals and companies can maintain operational efficiency and uphold the standards of safety and reliability that modern applications demand. The emphasis on quality materials, appropriate sizing, and correct installation cannot be overstated when dealing with the seemingly simple but critically important hose clamp.

Share

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.08,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.08,2025

-

Large Adjustable Stainless Steel Hose Clamp - Hebei Pux Alloy

NewsAug.08,2025

-

Premium Stainless Steel Hose Clip | Secure & Rust-Proof Clamps

NewsAug.08,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.07,2025

-

Large Stainless Steel Adjustable Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance,High Breaking Torque

NewsAug.07,2025