- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 17, 2024 12:32 Back to list

Hose Clamp Fire Safety Solutions for Reliable Industrial Applications and Manufacturing Standards

The Role of Hose Clamps in Fire Safety Insights from Leading Manufacturers

In the world of industrial equipment and safety protocols, hose clamps play a crucial yet often overlooked role, particularly in fire safety applications. As the demand for reliable fire prevention measures grows, manufacturers are innovating to ensure that their hose clamps meet the highest standards of performance and reliability. This article explores the significance of hose clamps in fire safety, highlighting key features that reputable manufacturers incorporate into their products, and the evolving landscape of fire safety technology.

Understanding Hose Clamps

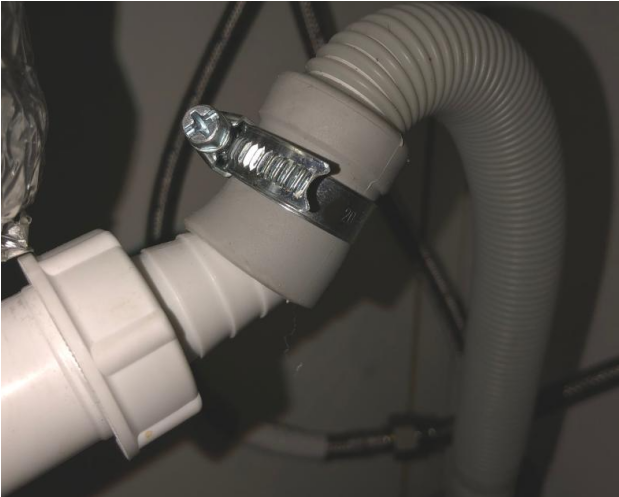

Hose clamps are mechanical devices used to secure the ends of hoses to fittings or to each other. Their primary purpose is to create a tight seal that prevents leaks and maintains pressure within the system. While hose clamps are commonly found in various applications—ranging from automotive to plumbing—their role in fire safety is particularly critical. Fire suppression systems, for example, rely heavily on the integrity of hose connections to deliver water or fire-retardant chemicals effectively.

Importance of Hose Clamps in Fire Safety

In fire prevention systems, hose clamps serve several vital functions

1. Leak Prevention In a fire emergency, any leak can compromise the effectiveness of the response. High-quality hose clamps ensure that hoses remain securely fastened, minimizing the risk of leaks that could hinder fire extinguishing efforts.

2. Pressure Maintenance Many fire suppression systems operate under high pressure. Hose clamps must withstand significant forces to keep hoses in place and ensure the consistent delivery of firefighting agents.

3. Material Compatibility Fire hoses often carry various chemicals. Hose clamps must be made from materials that can withstand these substances without degradation, ensuring long-term reliability.

4. Ease of Installation and Maintenance In emergency situations, time is of the essence. Efficient hose clamps that are easy to install and adjust can make a significant difference in the rapid deployment of fire suppression systems.

hose clamp fire manufacturer

Innovations by Manufacturers

Leading hose clamp manufacturers are continuously innovating to meet the demands of fire safety. Some of the notable advancements include

- Corrosion Resistance Manufacturers are now producing hose clamps from advanced materials such as stainless steel and specialty alloys that provide superior resistance to corrosion. This is particularly important in environments exposed to high humidity or harsh chemicals.

- High-Temperature Tolerance As fire safety systems need to operate effectively under extreme conditions, manufacturers are developing hose clamps that can maintain performance at elevated temperatures, preventing failure during critical moments.

- Adjustable Designs New designs featuring quick-release mechanisms allow for faster installation and adjustments, making them ideal for use in high-pressure situations where time is crucial.

- Smart Technology Integration Some businesses are even exploring technologies that allow for real-time monitoring of hose clamp integrity. Smart sensors can alert operators to potential failures, ensuring proactive maintenance and reducing the risk during a fire emergency.

Standards and Certifications

Reputable manufacturers prioritize compliance with international standards and certifications to guarantee the safety and efficacy of their hose clamps. Common certifications include those from organizations like the Underwriters Laboratories (UL) and the American Society for Testing and Materials (ASTM). These certifications ensure that hose clamps can perform under specified conditions, further instilling confidence in their use in fire safety applications.

Conclusion

As we're increasingly recognizing the importance of robust fire prevention strategies, the role of hose clamps cannot be understated. Manufacturers play a critical role in ensuring that these components are designed, tested, and manufactured to the highest standards. Investing in high-quality hose clamps is not merely a matter of efficiency; it is an essential aspect of fire safety that can mean the difference between life and death in emergency situations. As technology advances, we can expect even more innovations that enhance the reliability and effectiveness of hose clamps in safeguarding our communities against fire hazards.

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025