- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 02, 2024 15:14 Back to list

high quality automotive constant tension hose clamps

High-Quality Automotive Constant Tension Hose Clamps Ensuring Reliability and Performance

In the automotive industry, the integrity of various systems hinges significantly on the quality of components used. Among these, hose clamps play a crucial role, particularly in maintaining the efficiency of fluid transfer systems within vehicles. Constant tension hose clamps, known for their unique design and reliable performance, have emerged as a preferred choice for automotive applications.

Understanding Constant Tension Hose Clamps

Constant tension hose clamps are engineered to maintain optimal clamping force, irrespective of changes in temperature and pressure. Unlike standard hose clamps, which may loosen or lose grip as temperatures fluctuate, constant tension clamps are designed to expand and contract with the hose. This innovative feature ensures a consistent seal, reducing the risk of leaks in critical systems such as coolant lines, fuel delivery, and air intake.

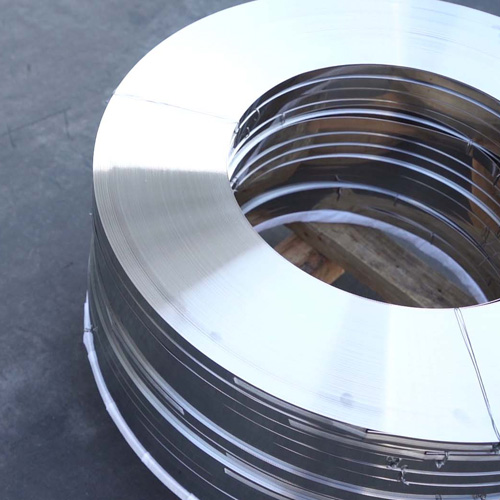

The Advantages of High-Quality Materials

One of the key factors that determine the performance and longevity of constant tension hose clamps is the material used in their construction. High-quality automotive clamps are typically made from stainless steel or premium-grade alloys, offering superior resistance to corrosion and wear. This is crucial in automotive applications where exposure to various chemicals and environmental conditions can lead to deterioration over time.

Moreover, high-quality clamps often feature additional coatings or finishes that enhance their durability, providing further protection against rust and oxidation

. By investing in superior materials, manufacturers can assure vehicle owners of the reliability and longevity of their hose clamp solutions.Precision Engineering for Optimal Performance

high quality automotive constant tension hose clamps

The precision in the manufacturing process of high-quality constant tension hose clamps contributes significantly to their effectiveness. Advanced production techniques ensure that each clamp is designed to provide uniform clamping force, which is essential for preventing hose damage. Poorly manufactured clamps can create uneven pressure, leading to hose failure or leakage—both of which can result in costly repairs and potentially dangerous situations.

Furthermore, high-quality hose clamps are often subjected to rigorous testing to meet industry standards. This commitment to quality assurance guarantees that these products can withstand the demanding environments they are placed in, whether in a high-performance vehicle or a standard commuter car.

Applications in the Automotive Industry

Constant tension hose clamps find applications across various aspects of the automotive industry. They are widely used in cooling systems, where maintaining fluid levels is critical for preventing engine overheating. Additionally, these clamps are employed in fuel systems, air conditioning units, and even exhaust systems, showcasing their versatility and reliability.

The automotive aftermarket also benefits from high-quality constant tension hose clamps, as vehicle owners seek to upgrade or replace failing components. Mechanics and DIY enthusiasts often prefer these clamps for their ease of installation and the peace of mind they provide, knowing that they are using a reliable product that will enhance the overall performance of the vehicle.

Conclusion

In summary, high-quality automotive constant tension hose clamps are essential components that contribute to the reliability and efficiency of various automotive systems. By ensuring a secure and consistent seal, these clamps help prevent leaks and failures, ultimately enhancing vehicle performance. As automotive technology continues to evolve, the demand for superior components like constant tension hose clamps will undoubtedly grow, cementing their place as a staple in the industry. Investing in high-quality clamps is not just a matter of performance but also a commitment to safety and reliability on the road.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion-Resistant, Adjustable Design

NewsAug.10,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology | Corrosion Resistant, Durable, Adjustable

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Industrial Applications, NIST Standards

NewsAug.10,2025

-

Durable Stainless Steel Hose Clip & Clamp Solutions

NewsAug.10,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Adjustable Design

NewsAug.09,2025