- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 22, 2024 12:43 Back to list

High-Performance Hose Clamps for Reliable High-Pressure Water Applications

High Pressure Water Hose Clamps An Essential Component for Fluid Transfer Systems

In industrial and agricultural sectors, high pressure water hose clamps play a crucial role in ensuring the safe and effective transfer of fluids. These clamps secure hoses to fittings, preventing leaks and maintaining the integrity of the entire system under high-pressure conditions. Understanding the importance of these components and the factors to consider when choosing them is essential for anyone involved in fluid transfer operations.

Importance of Hose Clamps

Hose clamps are used across a variety of applications, from automotive systems to irrigation setups, and even in household plumbing. Their primary function is to provide a tight seal at connection points between hoses and fittings. This sealing is particularly critical in high-pressure water applications where the force exerted on the hose can cause it to separate from the fitting if not properly secured. A failure at this connection can result in fluid leaks, damage to equipment, and potential safety hazards.

Types of High Pressure Water Hose Clamps

There are several types of hose clamps available for high-pressure applications. The most common types include

1. Gear Clamps These clamps consist of a band and a gear mechanism that allows for precise tightening. They are versatile and can be adjusted to fit various hose diameters, making them suitable for different applications.

2. T-Bolt Clamps Designed for high-pressure applications, T-bolt clamps have a threaded fastener that provides excellent tension. They feature a robust design that can handle extreme pressure, making them ideal for heavy-duty uses.

3. Constant Tension Clamps These clamps automatically adjust to changes in hose diameter due to temperature fluctuations or pressure variations. They ensure a consistent seal, minimizing the risk of leaks.

4. V-Band Clamps Commonly used in automotive and exhaust applications, V-band clamps form a secure connection through a unique design that grips both sides of the hose or pipe. They are effective in high-temperature and high-pressure environments.

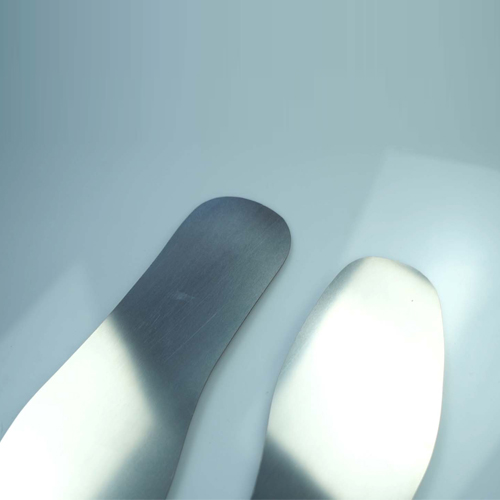

high pressure water hose clamps

Materials and Durability

The material of the hose clamp is another critical factor to consider. Most high pressure water hose clamps are made from stainless steel, carbon steel, or plastic. Stainless steel clamps are favored for their corrosion resistance and strength, making them suitable for outdoor and harsh environments. Carbon steel clamps, while strong, may require a protective coating to prevent rusting. Plastic clamps are lightweight and resistant to corrosion but may not handle extreme pressure as effectively as metal clamps.

Choosing the Right Clamp

When selecting a high pressure water hose clamp, several factors should be taken into consideration

- Pressure Ratings Ensure the clamp can handle the specific pressure levels of your application. Always choose a clamp rated for higher pressures than you expect to encounter to account for fluctuations.

- Hose Size Measure the diameter of the hose to choose a clamp that fits snugly. An improperly sized clamp can lead to ineffective sealing and leaks.

- Environmental Conditions Consider the environment in which the clamp will be used. If exposed to chemicals, high temperatures, or corrosive elements, select a material and design that can withstand those conditions.

- Installation Method Some clamps may require specialized tools for installation. Evaluate the ease of installation, especially if you frequently change hoses or fittings.

Conclusion

High pressure water hose clamps are indispensable for maintaining the integrity of fluid transfer systems. By understanding the different types, materials, and selection criteria, users can ensure they choose the right clamp for their specific needs. Investing in quality clamps not only enhances safety but also prolongs the lifespan of equipment, ultimately resulting in cost savings and improved operational efficiency. Whether in industrial settings or agricultural applications, the importance of reliable hose clamps cannot be overstated.

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025