- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 07, 2024 07:10 Back to list

High-Quality Hydraulic Hose Clamps Manufacturers for Reliable Pressure Applications

The Importance of High-Pressure Hydraulic Hose Clamps in Industrial Applications

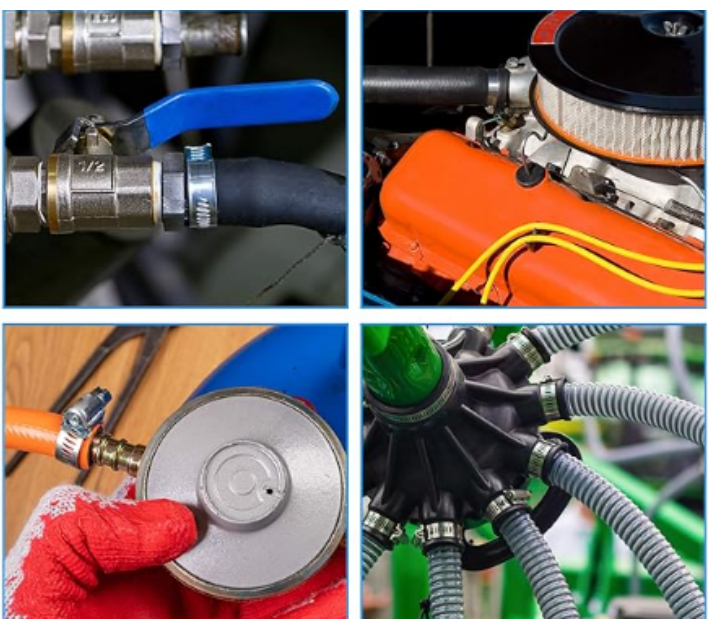

High-pressure hydraulic systems are integral to a multitude of industries, including construction, manufacturing, and automotive. Within these systems, the role of hydraulic hose clamps cannot be overstated. They are essential components that ensure the safe and efficient operation of hydraulic hoses. This article explores the significance of high-pressure hydraulic hose clamps, the factors influencing their production, and the role of factories in delivering reliable solutions.

Understanding Hydraulic Hose Clamps

Hydraulic hose clamps are devices used to secure hydraulic hoses in place within a hydraulic system. They prevent leaks and maintain pressure by holding the hoses tightly against fittings and connectors. Given that hydraulic systems operate at high pressures, the integrity of these clamps is critical. A failure in a hose clamp can lead to dangerous leaks, equipment malfunction, and costly downtime. Thus, quality and performance are paramount when selecting hose clamps.

Manufacturing High-Pressure Hydraulic Hose Clamps

Factories producing high-pressure hydraulic hose clamps employ advanced manufacturing techniques to ensure durability and reliability. Materials commonly used include stainless steel, carbon steel, and specialized alloys designed to withstand high pressure and corrosive environments. The manufacturing process typically involves several key steps

1. Material Selection Choosing the appropriate material based on the application requirements, including resistance to corrosion, pressure, and temperature.

2. Design and Engineering Engineers design hose clamps with specific load ratings and dimensions, ensuring compatibility with various hose sizes and types. Computer-aided design (CAD) tools aid in creating precise specifications.

3. Production The production phase may include processes like stamping, welding, and coating. Factories often utilize automated machinery to improve efficiency and consistency.

4. Quality Control Rigorous testing procedures ensure that each clamp can withstand the specified pressures. This might include tensile strength tests, pressure tests, and surface finish inspections.

high pressure hydraulic hose clamps factories

5. Certification Many manufacturers obtain certifications, such as ISO, to demonstrate their commitment to quality and safety standards.

The Role of Factories

Factories specializing in high-pressure hydraulic hose clamps play a crucial role in the supply chain. They not only manufacture the clamps but also contribute to research and development, pushing the boundaries of what these components can achieve. Modern factories focus on innovation, developing clamps that can handle increased pressure and adverse environmental conditions.

Furthermore, manufacturers often provide customization options. This flexibility allows customers to specify dimensions, materials, and finishes tailored to their specific needs. Such customization is essential in industries where standard solutions do not meet the rigorous demands of certain applications.

Importance of Quality and Reliability

In high-pressure applications, the failure of hose clamps can lead to catastrophic results. Equipment failure, safety hazards, and significant financial losses are just a few potential consequences. Therefore, investing in high-quality hydraulic hose clamps from reputable manufacturers is critical. Customers should look for suppliers that emphasize quality control and have a track record of reliability.

In addition to product quality, manufacturers that offer excellent customer service are invaluable. They provide technical support, assist with product selection, and often have inventory ready for immediate shipment, reducing lead times for their customers.

Conclusion

High-pressure hydraulic hose clamps are vital components in many industrial systems, and their importance cannot be overlooked. The manufacturing process, from material selection to quality control, significantly affects the end product. Factories dedicated to producing these critical components ensure that they meet the highest standards of safety and performance. As industries continue to evolve and push the limits of technology, the role of innovative and reliable hydraulic hose clamps will remain indispensable, safeguarding both equipment and personnel in high-pressure environments. For businesses relying on hydraulic systems, understanding the significance of these clamps and partnering with quality manufacturers is key to success.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025