- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 20, 2024 01:23 Back to list

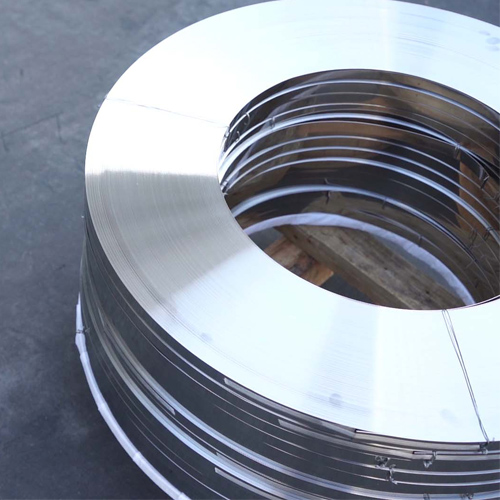

galvanized steel strip coil factory

Galvanized Steel Strip Coil Factory A Pillar of Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the significance of galvanized steel strip coils cannot be overstated. These products are pivotal in various industries, providing essential materials for construction, automotive, appliances, and more. The galvanized steel strip coil factory stands at the forefront of this sector, employing advanced technology and processes to meet the growing demands of consumers and businesses worldwide.

The Importance of Galvanization

Galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. This protective barrier is critical, as untreated steel can suffer from rust and degradation when exposed to moisture and air. The galvanized coating ensures that the underlying steel maintains its strength and integrity over time, making it suitable for a multitude of applications. In a galvanized steel strip coil factory, this process is meticulously executed to ensure high-quality products that adhere to industry standards.

Production Process

The manufacturing process in a galvanized steel strip coil factory is highly sophisticated and involves several key steps. It begins with the selection of high-grade steel, which is then cleaned to remove any impurities that could detract from the final product. This is followed by a series of processes, including annealing, during which the steel is heated to alter its properties and improve ductility.

Once the steel is prepared, it undergoes the galvanization process, typically by hot-dip galvanization in which the steel is submerged in molten zinc. This method is favored for its efficiency and the uniformity it offers in terms of coating thickness. The galvanized steel strips are then cooled and subsequently cut into coils, ready for distribution to various industries.

Quality Control

Quality control is paramount in any manufacturing setting, and a galvanized steel strip coil factory is no exception. Stringent testing protocols are employed to ensure that every coil meets the required specifications. This includes checking for coating thickness, adhesion, and resistance to corrosion. By adhering to these rigorous standards, factories can guarantee that their products not only meet customer expectations but also provide longevity and performance in their applications.

galvanized steel strip coil factory

Applications of Galvanized Steel Strip Coils

The versatility of galvanized steel strip coils is a key factor in their widespread use across different sectors. In the construction industry, for instance, these coils are commonly used for roofing, wall panels, and structural components. Their resistance to rust makes them ideal for outdoor applications, where exposure to the elements can cause substantial wear and tear.

In the automotive industry, galvanized steel is utilized for manufacturing body parts, chassis, and various structural elements. The lightweight yet durable nature of these coils contributes to improved fuel efficiency and overall vehicle performance. Similarly, in the appliance sector, galvanized steel is often used in the production of washing machines, refrigerators, and ovens, where durability and corrosion resistance are crucial.

Sustainability Practices

With increasing awareness of environmental issues, many galvanized steel strip coil factories are adopting sustainable practices. This includes recycling materials, optimizing energy consumption, and minimizing waste. The use of eco-friendly technologies in the galvanization process not only helps reduce the carbon footprint of production but also meets the rising consumer demand for sustainable products.

Future Prospects

Looking ahead, the galvanized steel strip coil industry is poised for growth. As global infrastructure projects continue to expand and industries seek to innovate, the demand for high-quality galvanized steel will only increase. Moreover, technological advancements such as automation and artificial intelligence are set to revolutionize production processes, enhancing efficiency and output.

In conclusion, the galvanized steel strip coil factory plays a vital role in modern manufacturing. By producing high-quality, durable materials that meet the needs of various industries, it supports economic growth, innovation, and sustainability. As we move further into the 21st century, the importance of such factories will undoubtedly continue to rise, underpinning the development of countless applications that form the backbone of our everyday lives.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025