- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 14, 2025 18:20 Back to list

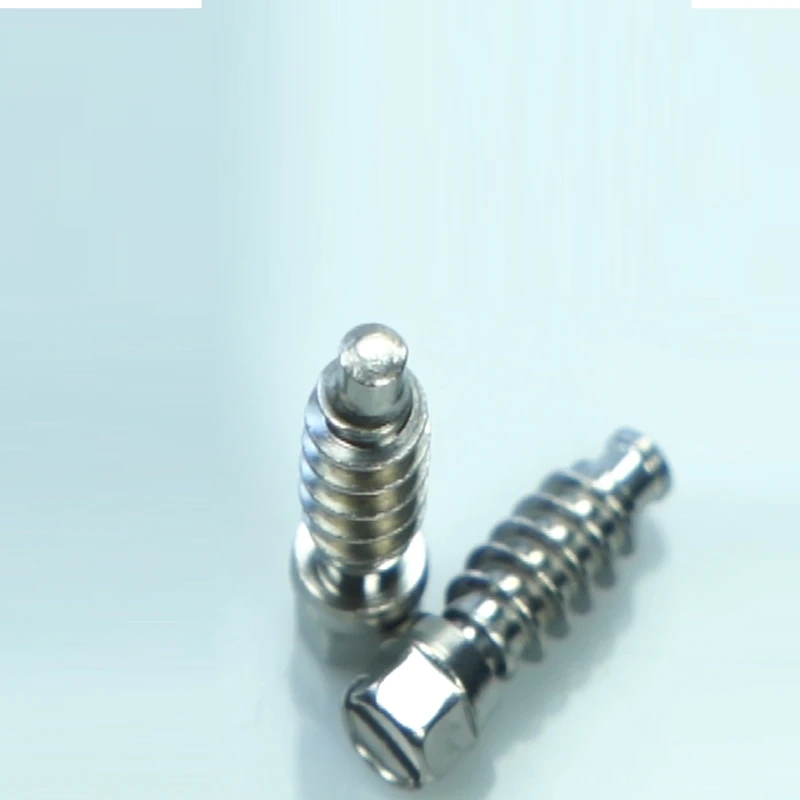

High Quality German Type Clamps Clips Stainless Steel Pipe Hose Clamp

Flat band hose clamps have emerged as the go-to solution for industries prioritizing secure and reliable fastening. Their unique design and robust functionality make them essential across various applications, from automotive to plumbing and industrial machinery. This article delves into the intricacies of flat band hose clamps, showcasing their unparalleled advantages and why they have become indispensable in many sectors.

In residential plumbing, the benefits of flat band hose clamps cannot be overstated. Homeowners and contractors alike appreciate their efficiency and reliability in both new installations and repairs. Given the constant fluctuation in water pressure, the need for a robust clamp that can withstand these changes without loosening is imperative. Flat band hose clamps meet this need admirably, offering a secure fasten that ensures seamless water flow and minimizes the risk of leak-induced water damage. The marine industry also heavily relies on flat band hose clamps due to their ability to withstand harsh, saline environments that are notorious for accelerating corrosion. In such settings, the non-conductive nature of the clamps is beneficial, preventing galvanic corrosion, which is critical in maintaining the longevity and safety of marine vessels. With the added assurance of high-tensile strength, flat band hose clamps contribute to maintaining the integrity of fuel lines, cooling systems, and other vital fluid paths essential for vessel operation. From a manufacturing perspective, flat band hose clamps are both a time-efficient and cost-effective choice. Producers benefit from the straightforward assembly process, reducing labor costs and enhancing overall production efficiency. The recyclability of stainless steel also resonates well with brands focused on sustainability, providing an eco-friendly solution that aligns with modern environmental standards. In conclusion, flat band hose clamps offer unmatched reliability and adaptability across multiple industries. Their innovative design and sturdy construction provide a perfect blend of strength, flexibility, and simplicity, ensuring secure connections that withstand the test of time and challenging environments. Whether in automotive, plumbing, marine, or manufacturing contexts, these clamps provide a high level of assurance and efficiency, positioning them as the preferred choice for professionals seeking durable clamping solutions. Investing in flat band hose clamps is a strategic step towards enhancing operational safety and longevity, reflecting a commitment to quality and innovation in industry standards.

In residential plumbing, the benefits of flat band hose clamps cannot be overstated. Homeowners and contractors alike appreciate their efficiency and reliability in both new installations and repairs. Given the constant fluctuation in water pressure, the need for a robust clamp that can withstand these changes without loosening is imperative. Flat band hose clamps meet this need admirably, offering a secure fasten that ensures seamless water flow and minimizes the risk of leak-induced water damage. The marine industry also heavily relies on flat band hose clamps due to their ability to withstand harsh, saline environments that are notorious for accelerating corrosion. In such settings, the non-conductive nature of the clamps is beneficial, preventing galvanic corrosion, which is critical in maintaining the longevity and safety of marine vessels. With the added assurance of high-tensile strength, flat band hose clamps contribute to maintaining the integrity of fuel lines, cooling systems, and other vital fluid paths essential for vessel operation. From a manufacturing perspective, flat band hose clamps are both a time-efficient and cost-effective choice. Producers benefit from the straightforward assembly process, reducing labor costs and enhancing overall production efficiency. The recyclability of stainless steel also resonates well with brands focused on sustainability, providing an eco-friendly solution that aligns with modern environmental standards. In conclusion, flat band hose clamps offer unmatched reliability and adaptability across multiple industries. Their innovative design and sturdy construction provide a perfect blend of strength, flexibility, and simplicity, ensuring secure connections that withstand the test of time and challenging environments. Whether in automotive, plumbing, marine, or manufacturing contexts, these clamps provide a high level of assurance and efficiency, positioning them as the preferred choice for professionals seeking durable clamping solutions. Investing in flat band hose clamps is a strategic step towards enhancing operational safety and longevity, reflecting a commitment to quality and innovation in industry standards.

Share

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

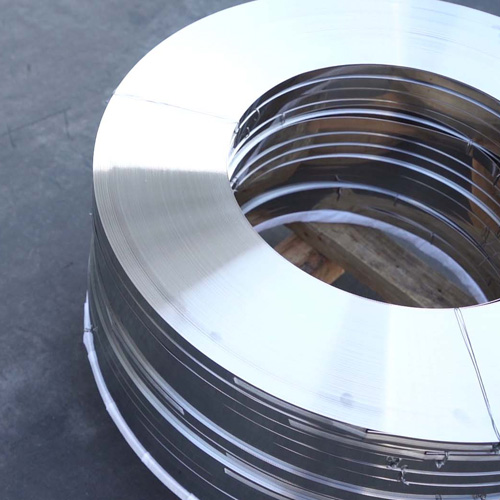

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025