- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 14, 2025 11:13 Back to list

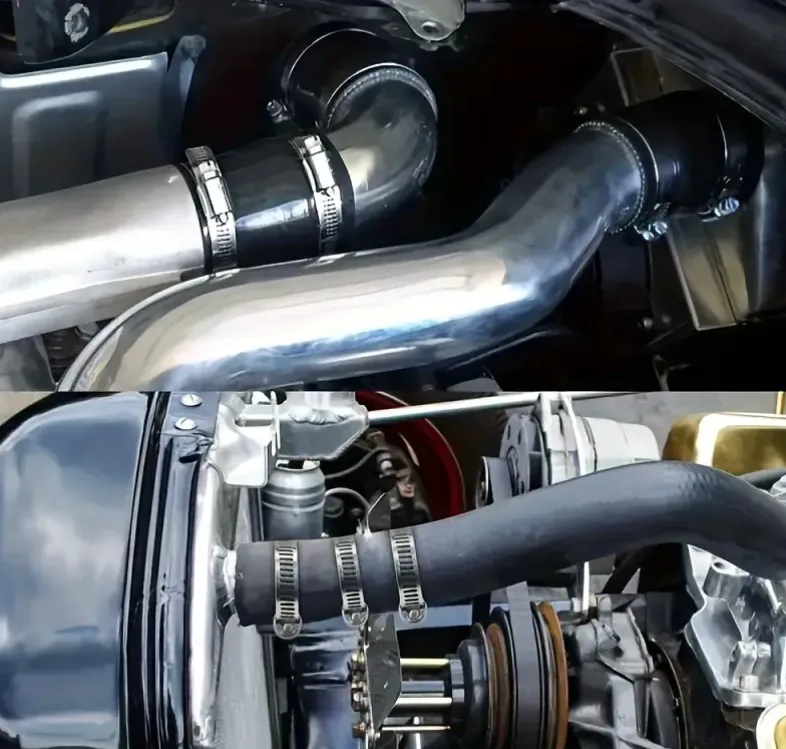

extra wide hose clamps

Extra wide hose clamps are an indispensable tool in various industries, ensuring secure connections and leak prevention across numerous applications. Their unique design and functionality cater to the needs of professional and DIY enthusiasts alike, seeking reliable and durable solutions for larger diameter hoses. Understanding the critical aspects of extra wide hose clamps can greatly enhance their effective use. Here, we delve into the essential features, benefits, and considerations for choosing the right clamp for your application.

The size of the clamp is another crucial consideration. Measure the hose's diameter to choose a clamp that fits securely without being overly tight, which could damage the hose. Ensure the clamp's width is appropriate for the hose and application, as an incorrectly sized clamp can compromise the integrity of the connection. Installation and Maintenance Proper installation is vital for the effective performance of extra wide hose clamps. It's important to position the clamp correctly on the hose, ensuring it sits evenly all around the circumference. Using the right tools, such as a torque wrench, can help achieve the correct tension without overtightening, which might cause damage. Regular maintenance checks are also recommended to ensure the clamps remain in good working condition. Periodically inspecting the clamps for tightening, wear, and damage can preempt potential issues before they escalate. In high-vibration applications, frequent checks and adjustments may be necessary to maintain optimal performance. Expert Recommendations Professionals with extensive experience in fields reliant on hose clamps underscore the importance of choosing quality over cost. Investing in high-quality extra wide hose clamps not only delivers reliable performance but also prolongs the lifespan of your hoses, thereby reducing the need for frequent replacements and minimizing downtime. Furthermore, consulting with experts or suppliers knowledgeable in specific industry requirements can provide valuable insights into the best clamp options. Such guidance ensures that each unique situation is addressed with a tailored solution, enhancing operational efficiency. In summary, extra wide hose clamps are a crucial component in ensuring secure and reliable hose connections across a multitude of applications. By understanding their design, selecting the right materials and sizes, and committing to proper installation and maintenance practices, users can maximize the clamps' effectiveness and longevity. As trusted components in high-stake environments, extra wide hose clamps continue to prove their worth in maintaining the integrity and safety of fluid and air transport systems.

The size of the clamp is another crucial consideration. Measure the hose's diameter to choose a clamp that fits securely without being overly tight, which could damage the hose. Ensure the clamp's width is appropriate for the hose and application, as an incorrectly sized clamp can compromise the integrity of the connection. Installation and Maintenance Proper installation is vital for the effective performance of extra wide hose clamps. It's important to position the clamp correctly on the hose, ensuring it sits evenly all around the circumference. Using the right tools, such as a torque wrench, can help achieve the correct tension without overtightening, which might cause damage. Regular maintenance checks are also recommended to ensure the clamps remain in good working condition. Periodically inspecting the clamps for tightening, wear, and damage can preempt potential issues before they escalate. In high-vibration applications, frequent checks and adjustments may be necessary to maintain optimal performance. Expert Recommendations Professionals with extensive experience in fields reliant on hose clamps underscore the importance of choosing quality over cost. Investing in high-quality extra wide hose clamps not only delivers reliable performance but also prolongs the lifespan of your hoses, thereby reducing the need for frequent replacements and minimizing downtime. Furthermore, consulting with experts or suppliers knowledgeable in specific industry requirements can provide valuable insights into the best clamp options. Such guidance ensures that each unique situation is addressed with a tailored solution, enhancing operational efficiency. In summary, extra wide hose clamps are a crucial component in ensuring secure and reliable hose connections across a multitude of applications. By understanding their design, selecting the right materials and sizes, and committing to proper installation and maintenance practices, users can maximize the clamps' effectiveness and longevity. As trusted components in high-stake environments, extra wide hose clamps continue to prove their worth in maintaining the integrity and safety of fluid and air transport systems.

Share

Next:

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025