- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jun . 25, 2024 23:55 Back to list

Efficient Narrow Hose Clamp Production in Modern Factory Settings

The Art of Precision Navigating the Wonders of Narrow Hose Clamps in Factory Settings

In the intricate tapestry of industrial production, one component stands as a testament to both engineering ingenuity and practicality - the narrow hose clamp. These seemingly simple devices, often unseen by the naked eye, play a pivotal role in ensuring the efficient flow of fluids and gases within complex machinery.

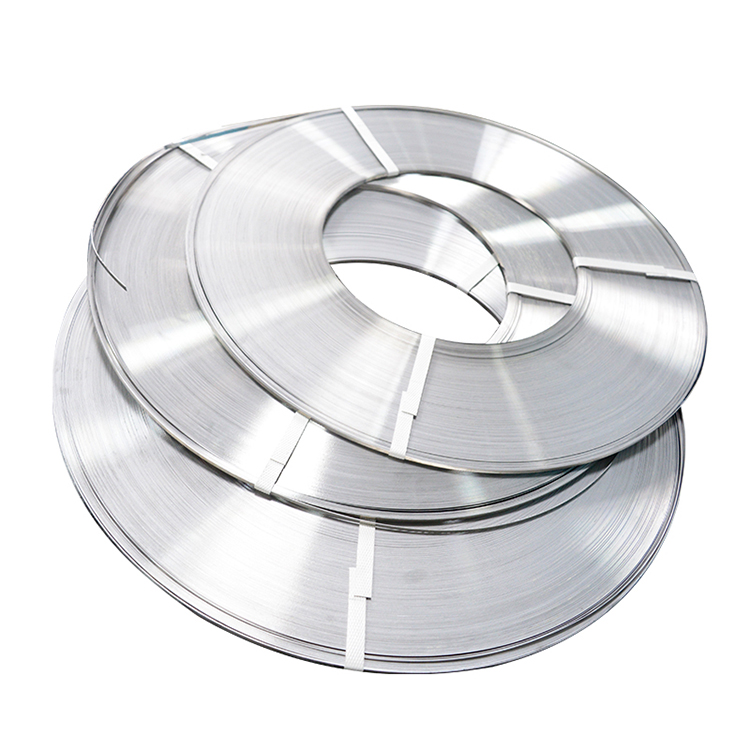

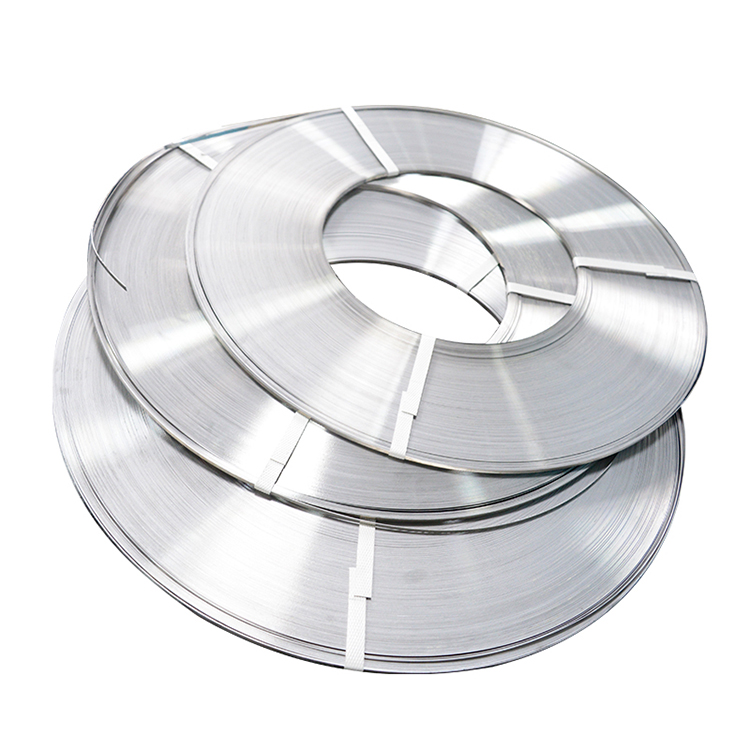

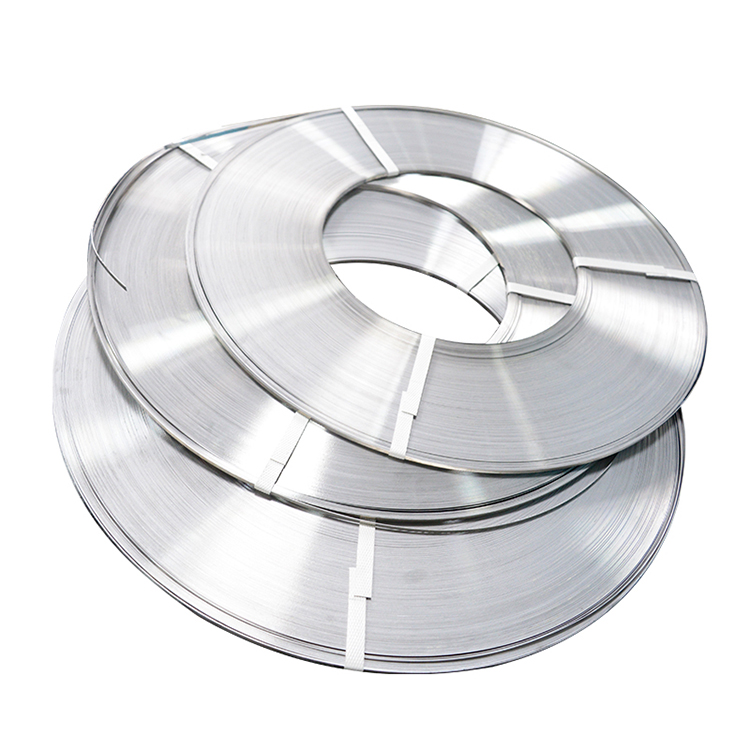

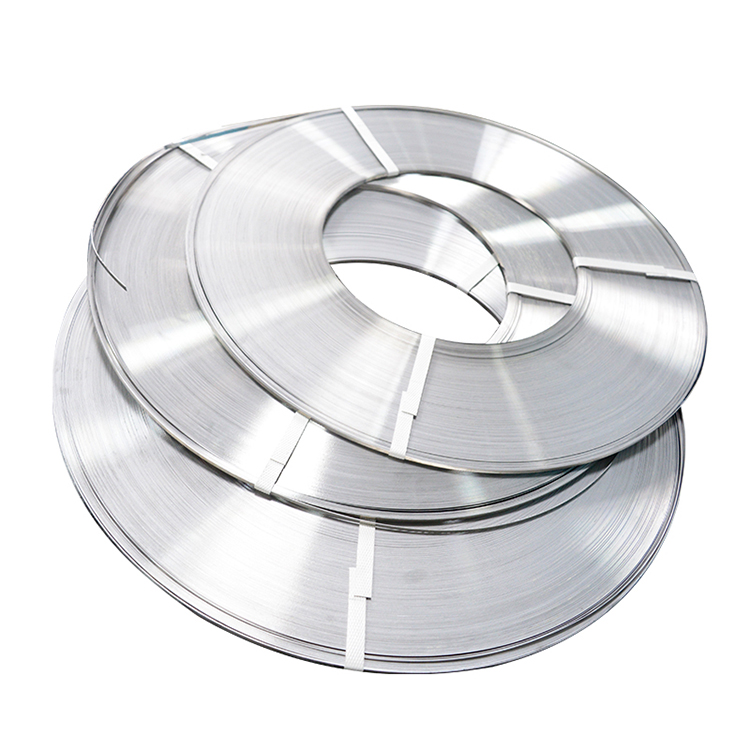

Narrow hose clamps, with their slender design, are specifically tailored for tight spaces where conventional clamps would be impractical. They are crafted from high-quality materials, typically stainless steel or lightweight aluminum, to withstand harsh working conditions and resist corrosion. The precision manufacturing process begins with meticulous design, factoring in the strength-to-weight ratio and the need for precise fit without compromising on durability.

The factories that specialize in producing these marvels operate like well-oiled machines themselves. From the initial design phase, engineers collaborate closely with production teams to create digital blueprints that guide the creation of each clamp. State-of-the-art computer-aided design (CAD) software is employed to optimize the clamp's form and function, ensuring optimal sealing and load-bearing capacity.

Once the design is finalized, raw materials are precisely cut and shaped using automated saws and milling machines. Each step is monitored under stringent quality control measures to maintain consistency and accuracy. The narrowness of the clamps demands extreme attention to detail, as even the slightest deviation can result in a faulty product.

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together narrow hose clamps factory. Workers monitor every movement, ensuring that the clamping mechanism is aligned perfectly. The final touch involves applying a layer of protective coating, either for corrosion resistance or aesthetics, depending on the application.

As the finished products roll off the assembly line, they find their way into countless industries – automotive, aerospace, food processing, and more. They secure pipes and hoses in machinery, enabling vital processes to function smoothly. In hospitals, they keep medical equipment connected, ensuring patient safety. In construction sites, they hold pipes steady during high-pressure water blasting or gas transmission.

The narrow hose clamp factory, a microcosm of modern industry, exemplifies the marriage of technology and craftsmanship. It underscores the importance of precision engineering in a world where efficiency and reliability are paramount. As we continue to advance, these humble yet indispensable components will remain at the forefront of innovation, silently securing the foundations of our industrial landscape.

narrow hose clamps factory. Workers monitor every movement, ensuring that the clamping mechanism is aligned perfectly. The final touch involves applying a layer of protective coating, either for corrosion resistance or aesthetics, depending on the application.

As the finished products roll off the assembly line, they find their way into countless industries – automotive, aerospace, food processing, and more. They secure pipes and hoses in machinery, enabling vital processes to function smoothly. In hospitals, they keep medical equipment connected, ensuring patient safety. In construction sites, they hold pipes steady during high-pressure water blasting or gas transmission.

The narrow hose clamp factory, a microcosm of modern industry, exemplifies the marriage of technology and craftsmanship. It underscores the importance of precision engineering in a world where efficiency and reliability are paramount. As we continue to advance, these humble yet indispensable components will remain at the forefront of innovation, silently securing the foundations of our industrial landscape.

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together

The assembly line is a symphony of precision, with robotic arms handling the delicate task of fitting components together narrow hose clamps factory. Workers monitor every movement, ensuring that the clamping mechanism is aligned perfectly. The final touch involves applying a layer of protective coating, either for corrosion resistance or aesthetics, depending on the application.

As the finished products roll off the assembly line, they find their way into countless industries – automotive, aerospace, food processing, and more. They secure pipes and hoses in machinery, enabling vital processes to function smoothly. In hospitals, they keep medical equipment connected, ensuring patient safety. In construction sites, they hold pipes steady during high-pressure water blasting or gas transmission.

The narrow hose clamp factory, a microcosm of modern industry, exemplifies the marriage of technology and craftsmanship. It underscores the importance of precision engineering in a world where efficiency and reliability are paramount. As we continue to advance, these humble yet indispensable components will remain at the forefront of innovation, silently securing the foundations of our industrial landscape.

narrow hose clamps factory. Workers monitor every movement, ensuring that the clamping mechanism is aligned perfectly. The final touch involves applying a layer of protective coating, either for corrosion resistance or aesthetics, depending on the application.

As the finished products roll off the assembly line, they find their way into countless industries – automotive, aerospace, food processing, and more. They secure pipes and hoses in machinery, enabling vital processes to function smoothly. In hospitals, they keep medical equipment connected, ensuring patient safety. In construction sites, they hold pipes steady during high-pressure water blasting or gas transmission.

The narrow hose clamp factory, a microcosm of modern industry, exemplifies the marriage of technology and craftsmanship. It underscores the importance of precision engineering in a world where efficiency and reliability are paramount. As we continue to advance, these humble yet indispensable components will remain at the forefront of innovation, silently securing the foundations of our industrial landscape. Share

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025