- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jul . 26, 2024 14:00 Back to list

Durable Wing Hose Clamps for Secure Connections in Automotive and Plumbing Applications

Understanding the Wing Hose Clamp A Guide to Its Utility and Benefits

When it comes to securing hoses in various applications, the wing hose clamp stands out as a reliable and versatile choice. This unique fastening device is designed to provide a secure grip on hoses, ensuring that fluid or air remains contained within them. Whether you’re a DIY enthusiast or a professional in plumbing, automotive, or agricultural fields, understanding the benefits and application of wing hose clamps is essential.

What is a Wing Hose Clamp?

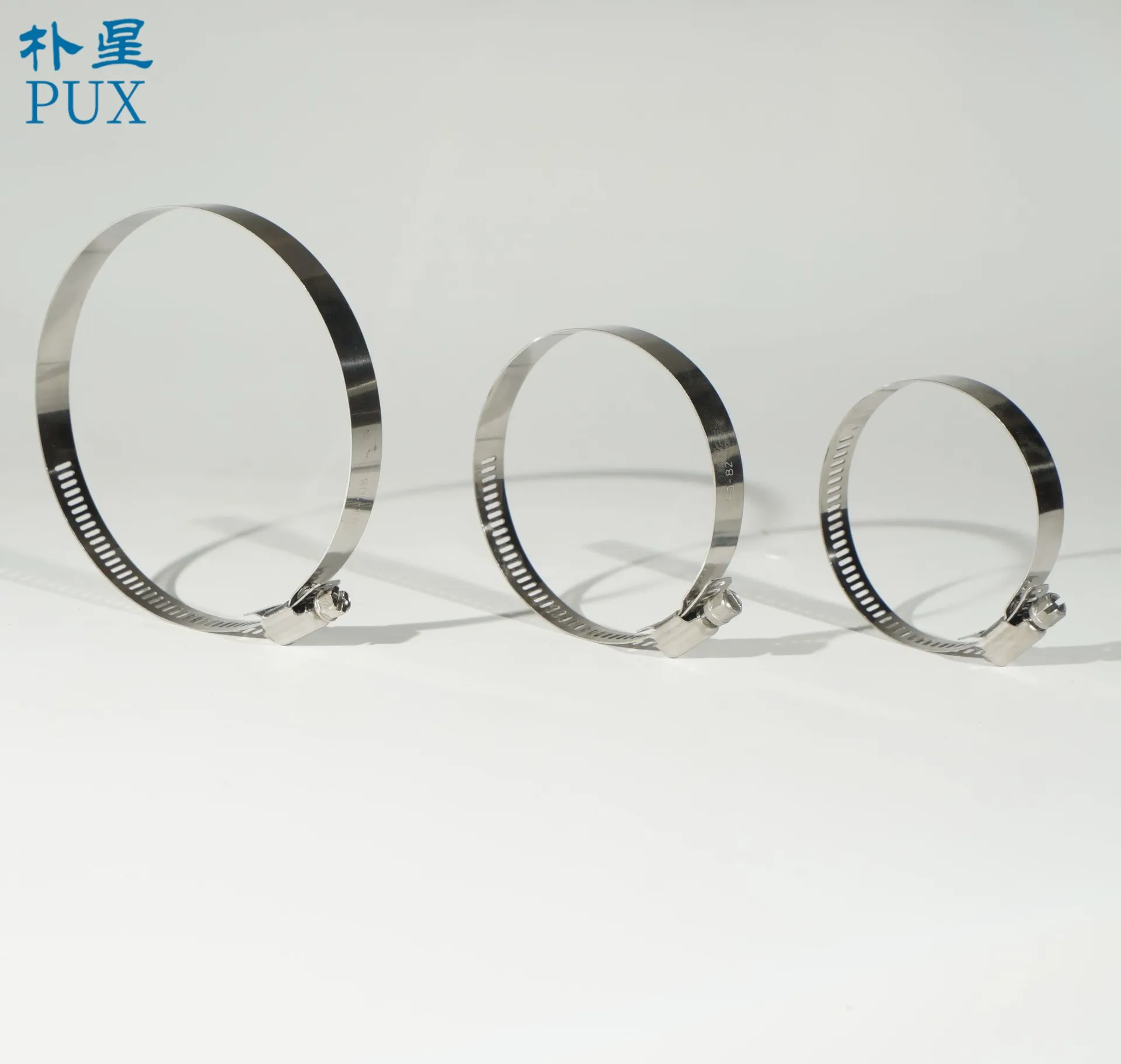

A wing hose clamp features a distinctive design that includes a pair of wings on either side of the clamp’s head. This design allows for easy manual tightening and loosening, making it user-friendly. Typically made from stainless steel or other corrosion-resistant materials, wing hose clamps are built to withstand various environmental conditions.

Key Advantages of Wing Hose Clamps

1. Ease of Use One of the primary advantages of wing hose clamps is their ease of installation. The winged design allows users to apply pressure and adjust the clamp without the need for specialized tools. This capability is particularly beneficial in circumstances where quick adjustments are necessary.

2. Versatility Wing hose clamps come in a range of sizes to accommodate different hose diameters. They can be used in various applications, from automotive engines to garden irrigation systems. Their versatility makes them a staple in both industrial and domestic settings.

3. Durability Constructed from high-quality materials, wing hose clamps are built to last. Whether exposed to high pressures, fluctuating temperatures, or corrosive substances, these clamps can maintain their integrity and performance over time.

4. Cost-Effective Compared to other fastening options, wing hose clamps are generally more affordable. Their simple design and widespread availability make them a cost-effective solution for anyone needing to secure hoses without compromising quality.

wing hose clamp

5. Reusability Unlike conventional clamps that may need to be replaced after a single use, wing hose clamps can often be reused multiple times. This feature not only enhances their cost-effectiveness but also supports sustainable practices by reducing waste.

Common Applications

Wing hose clamps are utilized in a variety of settings. In the automotive industry, they secure radiator and fuel hoses, ensuring that vital fluids do not leak. In agricultural settings, these clamps help maintain irrigation systems, preventing water loss and ensuring efficiency. Additionally, home DIY projects often involve wing hose clamps for plumbing repairs or when setting up water features in gardens.

Installation Tips

Installing a wing hose clamp is straightforward, but there are a few tips to ensure optimal performance

- Select the Right Size Ensure that the clamp fits snugly around the hose. A clamp that is too small can damage the hose, while one that is too large may not hold adequately. - Positioning Place the clamp at the right spot to provide an even distribution of pressure. This alignment is crucial for preventing leaks. - Tightening When tightening the clamp, ensure it is snug but not overly tight. Over-tightening can cause the hose material to deform or even break.

Conclusion

The wing hose clamp is a simple yet highly effective tool for anyone working with hoses. Its ease of use, durability, and versatility make it an essential item in various applications. By understanding how to properly select and install these clamps, users can ensure efficient operations in their projects, whether they are in a professional setting or tackling DIY tasks at home. Investing in quality wing hose clamps can save time, money, and headaches in the long run.

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, High Torque

NewsJul.31,2025

-

Durable Hose Clamps with GPT-4 Turbo Tech | Secure Sealing

NewsJul.31,2025