- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Aug . 20, 2024 14:00 Back to list

Camco Twist It Hose Clamps Manufacturer and Quality Assurance Solutions

Understanding Camco Twist It Hose Clamps A Comprehensive Overview of Their Factory Operations

Hose clamps are essential components in various applications, ensuring secure connections in plumbing, automotive, and marine setups. Among the many manufacturers in this field, Camco has established itself as a trusted name, particularly known for its innovative Twist It hose clamps. This article delves into the intricacies of the Camco Twist It hose clamps and the factory operations that bring this product to life.

What Are Camco Twist It Hose Clamps?

The Camco Twist It hose clamps are uniquely designed to provide a reliable solution for securing hoses and tubing. Unlike traditional hose clamps that require a screwdriver or special tools for adjustments, the Twist It clamps feature an easy-to-use twist mechanism. This allows users to quickly and easily adjust the diameter, making them perfect for applications where hoses need to be frequently removed or replaced, such as in RVs, boats, and various home projects.

The Manufacturing Process

At the heart of Camco's operations lies a well-structured manufacturing process that emphasizes quality, efficiency, and innovation. The factory is equipped with advanced machinery that automates many of the production processes while maintaining strict quality control standards. Here’s a closer look at the steps involved

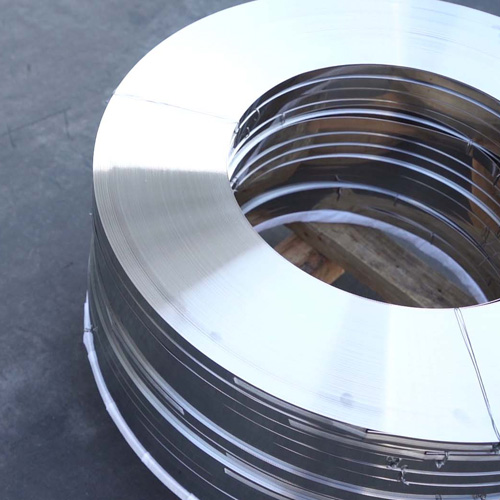

1. Material Selection The manufacturing process begins with the careful selection of materials. Camco prioritizes high-quality stainless steel and durable plastics to ensure the clamps can withstand environmental factors such as moisture, temperature changes, and corrosion.

2. Design and Engineering Engineers work collaboratively to design the Twist It mechanism, focusing on durability and ease of use. Prototyping and testing ensure that the final product meets the rigorous standards expected by customers.

camco twist it hose clamps factory

3. Production Lines Once the design is finalized, the factory floor springs into action. Automated production lines facilitate the efficient assembly of the clamps, with machines that cut, shape, and assemble parts with precision.

4. Quality Control Various quality control checkpoints are incorporated throughout the manufacturing process. Each batch of hose clamps undergoes rigorous testing for strength, flexibility, and ease of operation, ensuring that only the best products reach the market.

5. Packaging and Distribution After passing quality checks, the clamps are packaged in user-friendly designs that provide customers with clear instructions and specifications. The products are then sent to various distribution centers, ready to be shipped to retail partners and direct consumers.

Innovative Features

What sets the Camco Twist It hose clamps apart from their competitors? In addition to their easy-to-use twist mechanism, these clamps are designed to be versatile and adaptable. They can fit a wide range of hose sizes and are ideal for various applications. Their robust build quality ensures that they withstand high-pressure conditions and have a long service life.

Furthermore, Camco is attentive to customer feedback and continually seeks ways to improve its products. This commitment to innovation allows them to stay ahead of industry trends and cater to evolving consumer needs.

Conclusion

Camco Twist It hose clamps exemplify quality craftsmanship and thoughtful engineering. The factory’s systematic approach to manufacturing—highlighting material quality, precise engineering, and rigorous testing—ensures that they deliver reliable products for a wide array of applications. For anyone in need of a practical solution to hose security, Camco's Twist It hose clamps stand out as a top choice, providing users with both convenience and peace of mind. As the demand for effective hose clamps continues to grow, Camco remains committed to innovation and excellence in their manufacturing practices.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsAug.02,2025

-

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025