- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Oct . 13, 2024 01:51 Back to list

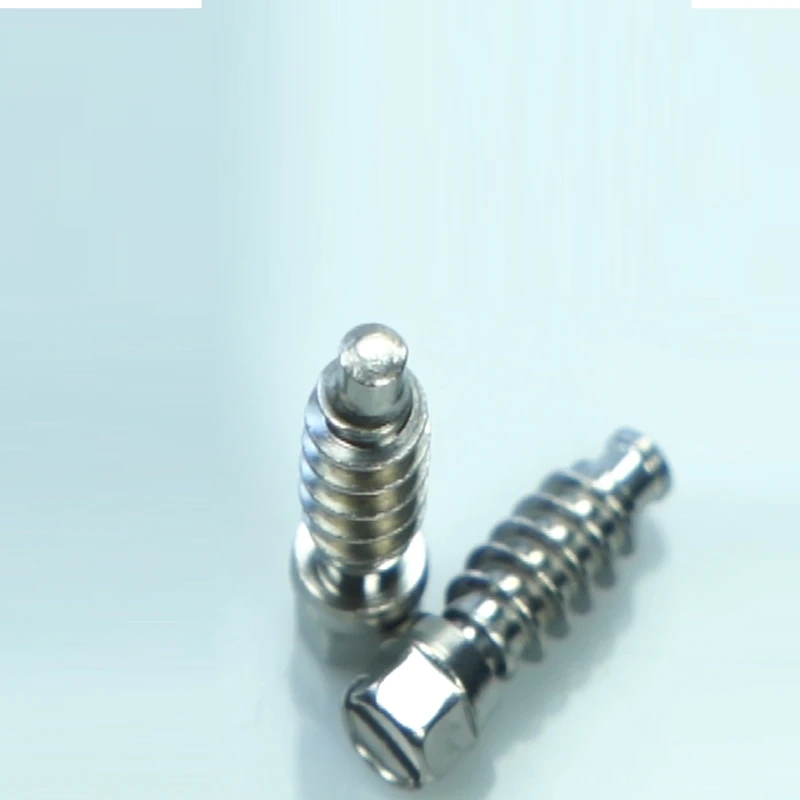

boost hose clamps factories

The Role of Boost Hose Clamps in Automotive Performance

In the realm of automotive performance enhancements, enthusiasts and professionals alike are constantly seeking ways to optimize engine output. One often-overlooked component in this quest for performance is the humble boost hose clamp. While it may seem like a minor detail, the functioning of boost hose clamps can play a pivotal role in the overall efficiency and power of a forced induction system. This article aims to explore the role, types, and importance of boost hose clamps, particularly focusing on their manufacturing process and the factories that produce them.

What are Boost Hose Clamps?

Boost hose clamps are specialized clamps used to secure hoses in high-pressure environments, such as those found in turbocharging and supercharging systems. They maintain the connection between the hose and the fittings, ensuring that boost pressure generated by the turbocharger or supercharger does not escape. A secure and leak-free connection is crucial for optimal performance, as even the slightest boost leak can lead to a significant drop in horsepower and torque.

Types of Boost Hose Clamps

There are several types of boost hose clamps, each with its unique features and applications. The most common types include

1. Semi-Rigid Clamps Made from stainless steel, these clamps are designed for standard hose connections. They offer durability and resistance to corrosion, making them suitable for various automotive applications.

2. T-Bolt Clamps Known for their strength, T-bolt clamps provide a secure grip on hoses under high pressure. They consist of a bolt that goes through a bridge, distributing pressure evenly around the hose. This type is especially beneficial in high-performance applications where hose integrity is critical.

3. V-Band Clamps These clamps offer a quick, efficient way to connect and disconnect components in the exhaust and intake systems. Their design enables uniform pressure distribution, minimizing the chances of leaks.

4. Constant Tension Clamps As engine temperatures fluctuate, these clamps adjust tension automatically, ensuring a secure fit over time. They are particularly useful in applications where thermal expansion is a concern.

Manufacturing Process and Factories

boost hose clamps factories

The production of boost hose clamps involves a series of meticulous processes to ensure quality and performance. Factories specializing in these components typically follow a streamlined procedure

1. Material Selection High-grade stainless steel is the primary material used in manufacturing boost hose clamps. Its resistance to rust and ability to withstand high pressures make it ideal for automotive applications.

2. Cutting and Shaping Sheets of stainless steel are cut into precise shapes and sizes. Advanced machinery, including laser cutters and CNC machines, ensures accuracy and consistency in production.

3. Forming and Assembly The cut pieces are formed into clamp shapes through bending and welding processes. T-bolt and V-band clamps require specific assembly techniques to ensure they function correctly.

4. Surface Treatment To enhance corrosion resistance, clamps may go through surface treatments such as polishing or plating. This treatment not only extends the life of the clamp but also improves its aesthetic appeal.

5. Quality Control Strict quality control measures are implemented throughout the manufacturing process. Every batch of clamps undergoes rigorous testing for durability and performance, ensuring they can withstand the harsh conditions of automotive environments.

Why Boost Hose Clamps Matter

The significance of boost hose clamps extends beyond mere functionality. They are instrumental in ensuring the reliability and efficiency of enhanced engine systems. Engine builders and tuners must choose the right type of clamp for their specific application to avoid potential problems associated with boost leaks.

Moreover, with advancements in automotive technology, the demand for high-quality boost hose clamps is on the rise. Manufacturers are continually innovating to create clamps that offer better performance and easier installation. Collectively, these improvements contribute to better fuel efficiency, increased horsepower, and an overall enhanced driving experience.

Conclusion

In summary, boost hose clamps, though often overlooked, are fundamental components in automotive performance. Their role in securing hoses under pressure is critical for optimizing engine output and maintaining efficiency in turbocharged and supercharged systems. As the automotive industry continues to evolve, the significance of boost hose clamps will only grow, matched by the innovations from factories dedicated to manufacturing these vital components. Investing in high-quality clamps should be a priority for anyone looking to enhance their vehicle's performance.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025