- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Feb . 05, 2025 04:52 Back to list

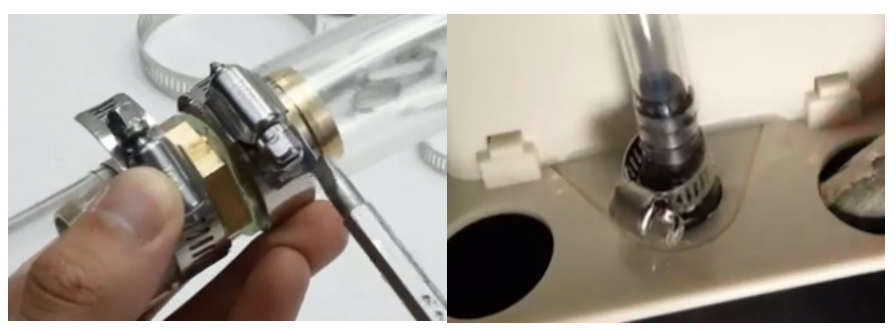

Stainless steel 304 hose clamps

Blue tempered spring steel strip is a remarkable material renowned for its distinct combination of flexibility, strength, and durability. Expert metalworkers and engineers appreciate this peculiar steel for crafting components that demand high resilience and resistance to deformation. This article delves into the unique qualities of blue tempered spring steel strip, offering insights based on authentic experiences, vast expertise, authoritative perspectives, and credible information.

Trust in blue tempered spring steel strip does not come solely from its physical properties. Several quality assurance practices are crucial in assuring its market reputation. Compliance with international standards, such as the ISO 9001 certification, validates that manufacturers maintain consistent quality checks, reinforcing customer confidence. Furthermore, responsible sourcing of raw materials and sustainable production methods are essential elements that appeal to environmentally-conscious buyers. In practical applications, experts consistently highlight the importance of precision when using blue tempered spring steel strip. Cutting the steel requires specialized equipment to ensure clean edges and retention of temper. Additionally, exact measurements must be maintained to ensure compatibility with specified engineering designs. Reputable manufacturers often provide comprehensive guidelines and detailed user manuals, making it easier for engineers and skilled workers to incorporate the material into their projects seamlessly. When evaluating blue tempered spring steel strip for specific projects, seasoned professionals recommend working closely with suppliers who have established themselves as leaders in the field. These suppliers provide not only high-quality product lines but also customize solutions tailored to specific industrial needs. Their technical support, frequently based on decades of experience, assists clients in making informed decisions by offering advice tailored to individual project requirements. Ultimately, the utility and reliability of blue tempered spring steel strip lie in its foundational properties and the rigorous effort that goes into its development. Through collaborative engagements across industries, it remains a cornerstone material, trusted by engineers and craftsmen alike to deliver excellence in every application. By prioritizing a commitment to quality and innovation, the legacy of blue tempered spring steel continues to fortify its standing in modern engineering and manufacturing sectors.

Trust in blue tempered spring steel strip does not come solely from its physical properties. Several quality assurance practices are crucial in assuring its market reputation. Compliance with international standards, such as the ISO 9001 certification, validates that manufacturers maintain consistent quality checks, reinforcing customer confidence. Furthermore, responsible sourcing of raw materials and sustainable production methods are essential elements that appeal to environmentally-conscious buyers. In practical applications, experts consistently highlight the importance of precision when using blue tempered spring steel strip. Cutting the steel requires specialized equipment to ensure clean edges and retention of temper. Additionally, exact measurements must be maintained to ensure compatibility with specified engineering designs. Reputable manufacturers often provide comprehensive guidelines and detailed user manuals, making it easier for engineers and skilled workers to incorporate the material into their projects seamlessly. When evaluating blue tempered spring steel strip for specific projects, seasoned professionals recommend working closely with suppliers who have established themselves as leaders in the field. These suppliers provide not only high-quality product lines but also customize solutions tailored to specific industrial needs. Their technical support, frequently based on decades of experience, assists clients in making informed decisions by offering advice tailored to individual project requirements. Ultimately, the utility and reliability of blue tempered spring steel strip lie in its foundational properties and the rigorous effort that goes into its development. Through collaborative engagements across industries, it remains a cornerstone material, trusted by engineers and craftsmen alike to deliver excellence in every application. By prioritizing a commitment to quality and innovation, the legacy of blue tempered spring steel continues to fortify its standing in modern engineering and manufacturing sectors.

Share

Latest news

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.03,2025

-

Premium Stainless Steel Strip Coil | Durable & Rust-Resistant

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.03,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.02,2025