- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 14, 2024 20:17 Back to list

beer line hose clamps supplier

The Importance of Hose Clamps and Choosing the Right Supplier for Beer Lines

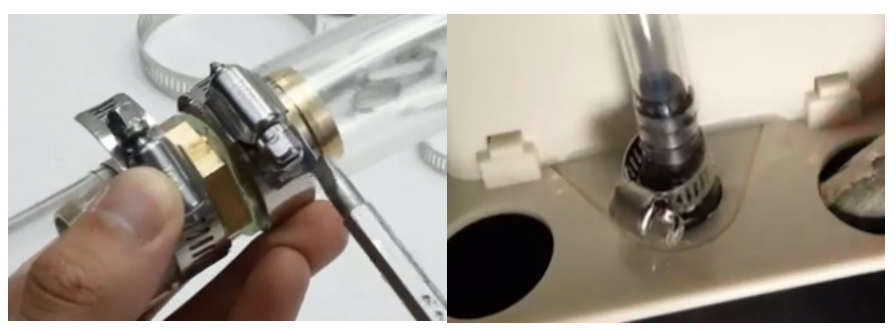

In the world of brewing and beer dispensing, every component plays a critical role in ensuring the quality, taste, and overall experience of the end product. Among these components, hose clamps might seem trivial, yet they are essential for maintaining the integrity of beer lines. This article explores the significance of hose clamps in beer dispensing systems and offers guidance on selecting a reliable supplier.

Understanding Hose Clamps in Beer Dispensing

Hose clamps are mechanical devices used to secure hoses onto fittings, preventing leaks and ensuring a tight seal. In beer dispensing systems, they play a crucial role in maintaining the quality of the beer. Loose clamps can lead to leaks, resulting in wastage, reduced quality, and even contamination. Properly secured hoses ensure that the beer is delivered from the keg to the tap without any risk of exposure to air or contaminants, preserving its freshness and flavor profile.

Types of Hose Clamps

There are various types of hose clamps suitable for beer line applications, including

1. Screw-Clamp Hose Clamps These are the most common type, adjustable by a screw mechanism that tightens the clamp around the hose, creating a secure seal.

2. Spring-Clamp Hose Clamps These utilize a spring mechanism to apply constant pressure to the hose. They are particularly useful for applications where vibration may loosen traditional clamps.

3. Ear-Clamps Often used in industrial applications, these clamps are applied using special tools but provide a robust seal.

Why Choosing the Right Supplier Matters

beer line hose clamps supplier

When it comes to sourcing hose clamps for beer dispensing systems, selecting the right supplier is paramount. Not all hose clamps are created equal, and opting for low-quality clamps can result in costly mistakes. Here are several factors to consider when choosing a supplier

1. Product Quality The integrity of the materials used in hose clamps is crucial. Stainless steel is often preferred for its resistance to corrosion and durability, especially in moist environments.

2. Customization Options A reliable supplier should offer customization options to ensure that the clamps fit specific hose diameters and design requirements.

3. Knowledge and Expertise An experienced supplier will understand the unique needs of the brewing industry, providing insights and recommendations for the best clamps for specific applications.

4. Customer Support Good suppliers offer excellent customer service, including support for installation and troubleshooting. This is particularly helpful for those new to the brewing process.

5. Reputation and Reliability Research potential suppliers by reading customer reviews and testimonials. A supplier with a solid reputation is more likely to provide high-quality products and reliability in delivery.

6. Certifications and Standards Ensure that the supplier meets industry standards and certifications, confirming the safety and quality of their products, particularly when food and beverage applications are involved.

Conclusion

In the brewing industry, attention to detail is paramount, and hose clamps, though small components, play a vital role in ensuring the successful and hygienic dispensation of beer. Choosing the right supplier for beer line hose clamps can significantly affect the overall quality of the brewing process and the final product. By prioritizing quality, expertise, and reliability, brewery operators can safeguard their products, ensuring that customers receive the best possible experience with every pour. Whether you are a small craft brewery or a large-scale operation, investing in high-quality hose clamps from a trusted supplier is a critical step in maintaining the integrity of your beer production and dispensing systems.

-

Precision High Quality Stainless Steel Strip Coils & Rolls

NewsAug.22,2025

-

Durable Adjustable Hose Clamps for Pipes & Radiators

NewsAug.21,2025

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025