- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Aug . 21, 2024 06:06 Back to list

3D Printing Solutions for Hose Clamp Manufacturers and Custom Design Services

The Role of 3D Printing in the Manufacturing of Hose Clamps

In recent years, 3D printing has transformed various sectors of manufacturing, including the production of hose clamps. These essential components, widely utilized in automotive, plumbing, and industrial applications, play a critical role in securing hoses to fittings, ensuring leak-proof connections. Manufacturers utilizing 3D printing technologies are positioned to enhance their operations, offering customized solutions, reducing costs, and improving efficiency.

Understanding Hose Clamps

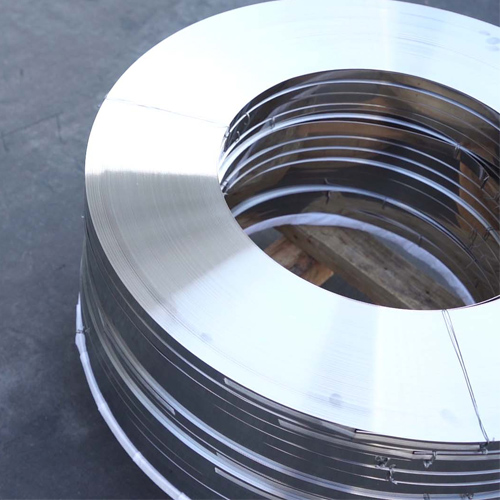

Hose clamps are mechanical devices that consist of a band or strap, typically made of metal or plastic, tightened around a hose. Their primary purpose is to secure the hose onto a fitting, preventing any leakage of fluids or gases. Various designs exist, including screw clamps, wire clamps, and spring clamps, each serving a unique function based on the requirements of the application.

In industries that demand precision and customization—such as aerospace and automotive—standard hose clamps may not meet technical specifications. Traditional manufacturing methods often involve lengthy lead times and substantial inventory costs. Here, 3D printing offers a solution that can significantly streamline the process.

Benefits of 3D Printing in Hose Clamp Manufacturing

1. Customization One of the most significant advantages of 3D printing is the ability to create custom-designed hose clamps tailored to specific needs. Engineers can design hose clamps that fit unique dimensions, accommodate varying pressure requirements, or integrate additional features, improving overall functionality.

2. Rapid Prototyping 3D printing allows manufacturers to quickly produce prototypes, enabling faster testing and design iterations. This capability minimizes the time from concept to production, allowing for more agile responses to market demands and reducing time to market significantly.

hose clamp 3d manufacturers

3. Cost-Effectiveness Traditional manufacturing processes often require expensive tooling and molds, especially for small production runs. 3D printing eliminates the need for these investments, allowing manufacturers to produce hose clamps in smaller quantities without incurring significant costs. This cost efficiency becomes particularly crucial for startups and small businesses looking to establish a foothold in the market.

4. Material Flexibility 3D printing utilizes a wide range of materials, including various plastics and metals. Manufacturers can choose the most suitable material based on factors such as strength, weight, and resistance to corrosion or temperature. This flexibility opens the door to innovations in hose clamp design and performance.

5. Sustainability 3D printing is often more environmentally friendly than traditional manufacturing methods. It generates less waste because materials are added layer by layer, and the ability to produce on-demand reduces overproduction and excess inventory.

Challenges and Considerations

While the benefits of 3D printing for hose clamps are clear, several challenges remain. The technology is continually evolving, and manufacturers must stay updated on the latest advancements to harness its full potential. Additionally, regulatory compliance and material certification are critical in industries like aerospace and automotive, where safety is paramount.

Moreover, while the initial investment in 3D printing technology may be high, the long-term savings and flexibility it offers often justify the expense. Companies looking to incorporate 3D printing into their hose clamp manufacturing processes must assess their specific needs and invest in suitable equipment and training for their workforce.

Conclusion

The integration of 3D printing into hose clamp manufacturing signifies a significant leap towards more efficient, customizable, and sustainable production processes. As manufacturers adopt this technology, industries can expect improved product offerings, faster lead times, and reduced costs, making 3D printing an essential element of modern hose clamp manufacturing. Embracing these innovations will be crucial for manufacturers seeking to maintain a competitive advantage in an ever-evolving market landscape.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025