- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 31, 2024 21:16 Back to list

Exploring 208 Factories Specializing in 3% Hose Clamp Manufacturing and Innovations

Understanding the Role and Impact of Hose Clamp Factories in the Industry

In the vast and intricate web of industrial operations, hose clamps play a crucial role in ensuring the safe and efficient functioning of machinery and automotive systems. These small yet vital components are designed to hold hoses tightly in place, preventing leaks and ensuring that fluid transfer systems operate seamlessly. Given the prevalence of hose clamps in various sectors, it is essential to examine the factories that produce them, focusing on their functions, manufacturing processes, innovations, and the challenges they face.

The Significance of Hose Clamps

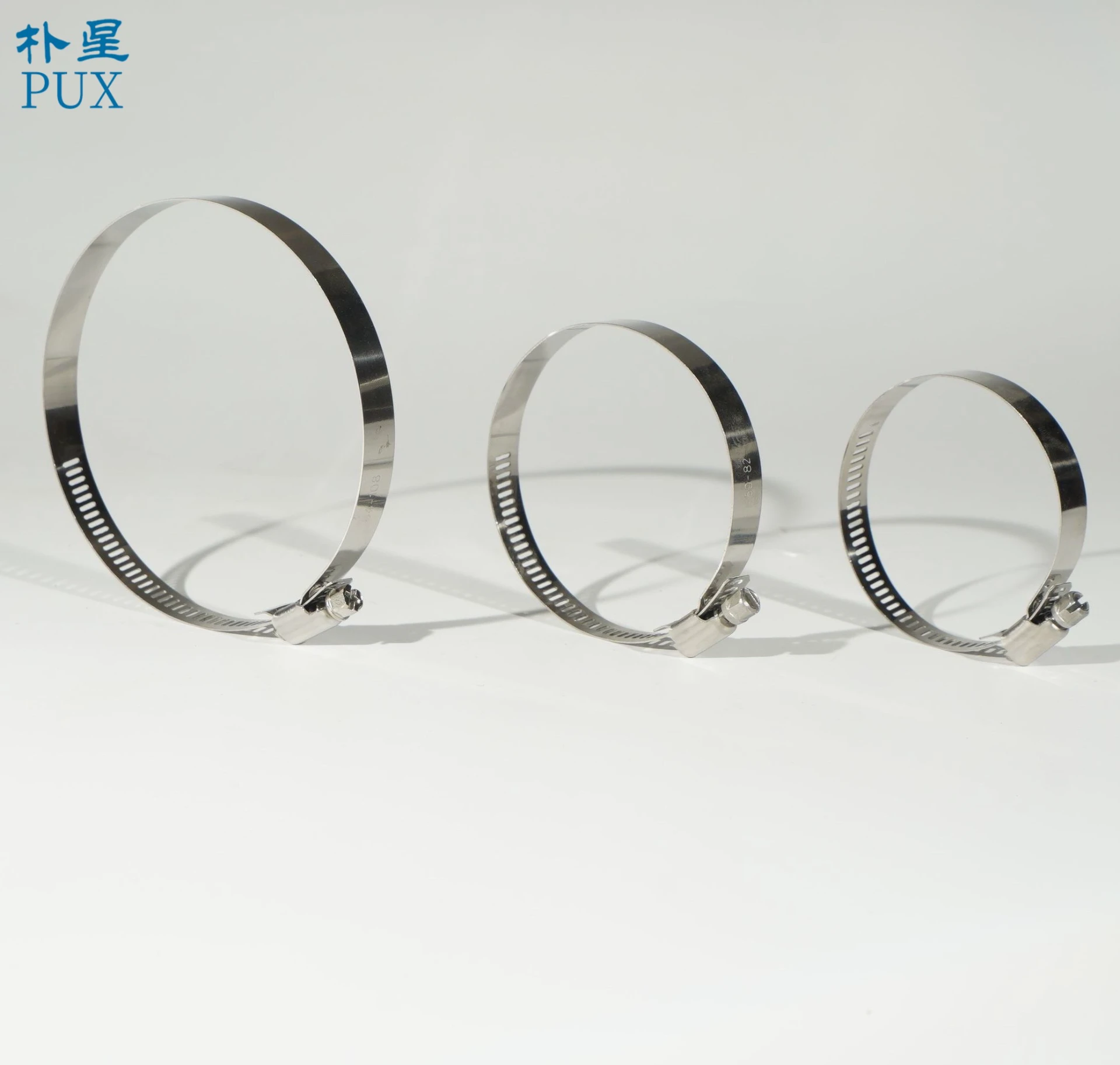

Hose clamps are widely used in automotive, aerospace, plumbing, and agricultural applications. Their primary purpose is to secure hoses onto fittings such as pipes or valves, which is critical in preventing fluid leaks. With the increasing complexity of modern machinery and vehicles, the demand for high-quality, durable hose clamps has surged. This demand has led to the establishment of numerous factories specializing in their production.

The Manufacturing Process

The manufacturing of hose clamps involves several key steps. Firstly, factories source raw materials, primarily stainless steel, carbon steel, or plastic, depending on the desired product specifications. The choice of material is crucial as it influences the durability and corrosion resistance of the clamps.

Once the materials are procured, the production process begins. Techniques such as stamping, welding, and molding are utilized to create the various components of the clamps. Automated machinery often plays a significant role in this process, enhancing precision and efficiency. Quality control is paramount; after the production phase, clamps undergo rigorous testing to ensure they meet industry standards and can withstand pressure without failure.

Innovations in Hose Clamp Production

3 8 hose clamp factories

As industries evolve, so too do the technologies and processes used in hose clamp manufacturing. Factories are increasingly integrating advanced technologies such as computer-aided design (CAD) and robotics to enhance productivity. CAD allows for the design of highly intricate and customized clamps that meet specific client needs while robotics streamline the assembly line, reducing human error and production time.

Moreover, the demand for sustainable practices is compelling factories to adopt eco-friendly materials and processes. Innovations such as the use of recycled materials and energy-efficient machinery not only meet environmental standards but also appeal to a growing consumer base increasingly concerned with sustainability.

The Challenges Faced by Hose Clamp Factories

Despite the advancements and significance of hose clamp factories, they face numerous challenges. One major issue is the fluctuating cost of raw materials. As prices vary due to market conditions, factories must find ways to optimize their production processes without compromising on quality, which can put a strain on profit margins.

Another hurdle is the competition in the global market. With numerous manufacturers offering similar products, companies are constantly in a race to offer better quality at competitive prices. This competition necessitates continuous innovation and improvement, compelling factories to invest in research and development.

Conclusion

Hose clamp factories are integral to the industrial landscape, providing crucial components that ensure the reliable performance of various systems. By understanding their manufacturing processes, the innovations they embrace, and the challenges they face, stakeholders can appreciate the complexity and importance of these factories. As technology continues to advance and industries evolve, hose clamp factories will undoubtedly adapt, ensuring they meet the increasing demands of quality and sustainability. The future of hose clamp manufacturing appears promising, with the potential for even greater advancements and contributions to the industrial sector. In a world that increasingly prioritizes efficiency and sustainability, the role of hose clamps and their manufacturers becomes ever more critical.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025