- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 25, 2024 00:19 Back to list

316 stainless hose clamps factories

Understanding 316 Stainless Steel Hose Clamps Factories and Manufacturing Processes

In the world of industrial hardware and fittings, hose clamps play a critical role in securing hoses and tubes in various applications, ranging from automotive engineering to plumbing systems. Among the various materials used for hose clamps, 316 stainless steel stands out due to its superior properties, particularly in corrosive environments. In this article, we will explore the features of 316 stainless steel hose clamps, their manufacturing processes, and the leading factories that produce them.

The Importance of 316 Stainless Steel

316 stainless steel is an alloy that includes molybdenum, which enhances its resistance to corrosion, especially in chlorinated environments. This makes it particularly suitable for marine applications, chemical processing, and food processing industries. The superior strength and durability of 316 stainless steel also make it an ideal choice for high-pressure and temperature applications.

Hose clamps made from 316 stainless steel are typically used where standard stainless steel clamps may fail. Their ability to withstand high temperatures and aggressive chemicals makes them indispensable in various sectors. From securing hoses that carry seawater to those that transport chemicals, 316 stainless steel clamps provide peace of mind and reliability.

Manufacturing Processes

The production of 316 stainless steel hose clamps involves several key processes that ensure the clamps meet stringent quality standards. The following outlines the typical steps involved in the manufacturing process

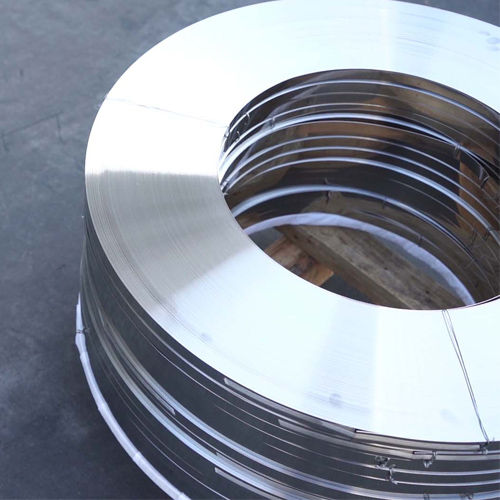

1. Material Sourcing The first stage is sourcing high-quality 316 stainless steel. Reliable suppliers are crucial for ensuring the material's consistency and purity, which directly affects the mechanical properties of the final product.

2. Cutting and Forming The stainless steel sheets or strips are cut into suitable sizes and shapes. This is usually done using advanced machinery to ensure precision. Forming processes, such as bending and shaping, are applied to create the desired clamp configuration.

3. Welding For clamps that require a welded design to hold several sections together, manufacturers use TIG (Tungsten Inert Gas) welding techniques to ensure strong and durable joints. This process ensures that the welding does not compromise the corrosion resistance of the stainless steel.

4. Finishing After forming and welding, the clamps undergo various finishing processes. This can include polishing, passivation, and surface treatment. These processes not only enhance the aesthetic appeal of the clamps but also improve their corrosion resistance.

316 stainless hose clamps factories

5. Quality Control Before reaching the market, each batch of 316 stainless steel hose clamps undergoes rigorous quality control testing. This may involve stress tests, dimensional checks, and corrosion resistance tests. Factories adhere to international standards, ensuring that their products meet specific regulatory requirements.

6. Packaging and Distribution Finally, the clamps are packaged securely for distribution. Many manufacturers offer customizable packaging options, including branding opportunities for businesses that plan to resell the product.

Leading Manufacturers of 316 Stainless Steel Hose Clamps

Several factories specialize in the production of 316 stainless steel hose clamps, catering to both local and international markets. Some well-known manufacturers have established a reputation for quality, innovation, and customer service.

1. Oetiker Based in Switzerland, Oetiker is recognized as a leader in the manufacturing of fastening solutions, including hose clamps. Their 316 stainless steel clamps are widely used in automotive and industrial applications, known for their reliability and performance.

2. Norma Group With a global presence, Norma Group specializes in high-quality hose clamps designed for a wide range of applications. Their commitment to sustainability and innovation makes them a preferred choice for many industrial sectors.

3. Abbott Rubber Company A U.S.-based manufacturer, Abbott Rubber offers a comprehensive range of hose clamps made from 316 stainless steel. Their products are particularly popular in the agricultural and marine industries.

4. Parker Hannifin This multinational corporation is known for its expertise in motion and control technologies. Parker’s hose clamps are designed for high-performance applications, providing users with durable and effective solutions.

Conclusion

316 stainless steel hose clamps are essential components in numerous industrial applications, thanks to their exceptional durability and resistance to corrosion. The manufacturing process involves several critical stages, from material sourcing to quality control, ensuring that the final product meets the highest standards. With leading manufacturers dedicated to producing reliable clamps, industries can confidently utilize these products for their operational needs. As technology and materials continue to evolve, we can expect even greater advancements in hose clamp design and functionality in the future.

-

Heavy Duty Hose Clamps: Premium Stainless Steel & Adjustable

NewsAug.19,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy|Durable Corrosion Resistance&Adjustable Design

NewsAug.18,2025

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.18,2025

-

American Style Adjustable Hose Clamps for Pipe & Radiator

NewsAug.18,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.|Corrosion Resistance, Adjustable Design

NewsAug.17,2025