- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 16, 2024 22:10 Back to list

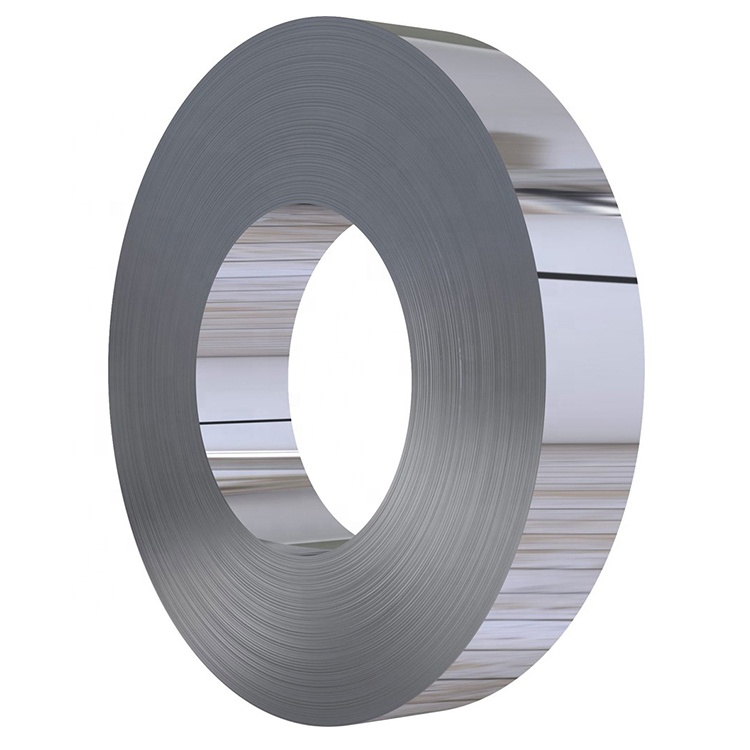

316l stainless steel strip supplier manufacturers

The Role of 316L Stainless Steel Strip Suppliers and Manufacturers

In today’s competitive market, the demand for high-quality materials plays a pivotal role in the manufacturing processes across various industries. One such material that has gained immense popularity is 316L stainless steel. Known for its excellent corrosion resistance, durability, and versatility, 316L stainless steel is widely used in applications ranging from marine environments to chemical processing. This article aims to explore the significance of 316L stainless steel strip suppliers and manufacturers and the factors to consider when choosing them.

Understanding 316L Stainless Steel

316L stainless steel is an austenitic grade that contains a higher nickel content than other stainless steels, such as 304. The addition of molybdenum enhances its resistance to pitting and crevice corrosion in chloride environments. It is particularly favored in environments where exposure to corrosive agents is likely, such as in the food and pharmaceutical industries.

The L in 316L refers to low carbon, which means that it contains a lower carbon content than standard 316 stainless steel. This characteristic greatly reduces the risk of carbide precipitation during welding, making 316L steel an excellent choice for weldable applications.

The Importance of Quality Suppliers and Manufacturers

When it comes to sourcing 316L stainless steel strips, the quality of the supplier or manufacturer is paramount. High-quality stainless steel strips are essential for ensuring the longevity and performance of the final product. Here are several reasons why choosing reliable suppliers and manufacturers is critical

1. Material Integrity High-quality suppliers adhere to strict standards and certifications, ensuring that their products meet industry requirements. This focus on quality helps prevent issues related to material integrity, such as brittleness or susceptibility to corrosion.

2. Customization Capabilities Not all applications require the same thickness or finish of stainless steel strips. Reliable manufacturers often offer customized solutions to meet specific project needs. This versatility allows businesses to optimize their processes and design more efficient products.

3. Supply Chain Efficiency Established suppliers have streamlined supply chain processes that guarantee timely delivery. In industries where time-to-market is crucial, the ability to receive materials promptly can significantly impact a company's bottom line.

4. Technical Support Leading manufacturers typically have experienced teams who can provide technical support and guidance. This support can be invaluable, especially when high-performance materials are required for complex applications.

316l stainless steel strip supplier manufacturers

5. Competitive Pricing While quality should never be compromised, reliable suppliers often offer competitive pricing structures. By forming partnerships with trusted manufacturers, businesses can reduce their material costs without sacrificing quality.

Factors to Consider When Choosing a Supplier

When selecting a 316L stainless steel strip supplier or manufacturer, consider the following factors

1. Reputation and Experience Research potential suppliers to understand their market reputation and years of experience in the industry. Established companies with a proven track record are often more reliable.

2. Certifications and Standards Ensure that the supplier adheres to necessary industry standards and holds relevant certifications, such as ISO 9001. Compliance guarantees that the product meets safety and quality regulations.

3. Range of Products A supplier that offers a wide range of 316L stainless steel products ensures that you can source all your material needs from one location, simplifying procurement efforts.

4. Customer Reviews and Testimonials Look for customer feedback and testimonials to gauge the supplier's commitment to quality and service. Positive reviews often reflect a supplier’s reliability and customer satisfaction.

5. After-Sales Support After purchasing, the relationship with the supplier should continue. Evaluate their after-sales support policies, including handling returns, defects, or any issues that may arise post-delivery.

Conclusion

Choosing the right 316L stainless steel strip supplier or manufacturer is critical for the success of businesses that utilize this essential material. By considering factors such as reputation, certifications, customization options, and support services, companies can ensure they partner with a reliable source that meets their needs. In an increasingly competitive landscape, the quality of materials directly affects product performance, making it imperative to select suppliers who prioritize excellence. By doing so, businesses not only enhance their operations but also affirm their commitment to quality and reliability in the marketplace.

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsAug.02,2025

-

High Quality Precision Stainless Steel Strip - GPT-4-Turbo Grade

NewsAug.02,2025

-

Heavy Duty Hose Clamp | Premium Durability & Security

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.01,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsJul.31,2025