- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Dec . 21, 2024 11:27 Back to list

Top Manufacturers of 1/4 Inch Hose Clamps for Quality Performance and Durability

The Importance of Hose Clamps A Comprehensive Overview of 1/4 Hose Clamp Factories

Hose clamps, while often overlooked, play a crucial role in a myriad of applications across various industries. Specifically, 1/4 hose clamps are vital components in ensuring that hoses remain securely connected to fittings, preventing leaks, and maintaining the efficiency of systems ranging from automotive to industrial applications. This article delves into the significance of 1/4 hose clamp factories, the manufacturing process, quality standards, and their role in the economy.

The Role of Hose Clamps

Hose clamps are typically made from materials such as stainless steel, zinc-plated steel, or plastic. Their primary function is to provide a strong grip on hoses, which is essential for the transfer of liquids and gases. The 1/4 size is particularly relevant, as it is commonly used in smaller hoses that are found in various applications, including irrigation systems, automotive fuel lines, and HVAC systems. These clamps must be robust enough to withstand fluctuations in pressure and temperature, which is why the quality of the manufacturing process is of utmost importance.

Manufacturing Process

The manufacturing of 1/4 hose clamps involves several critical steps, each contributing to the overall quality and reliability of the final product

1. Material Selection The first step involves choosing the appropriate materials. Stainless steel is frequently preferred due to its resistance to corrosion and strength, which ensures durability.

2. Cutting and Shaping Once materials are selected, they are cut to size and shaped into the desired form. This stage may involve advanced machinery such as CNC (Computer Numerical Control) machines, which ensure precision in manufacturing.

3. Coating To enhance durability, clamps may undergo a coating process that protects them from environmental factors. Zinc plating is common, as it offers corrosion resistance.

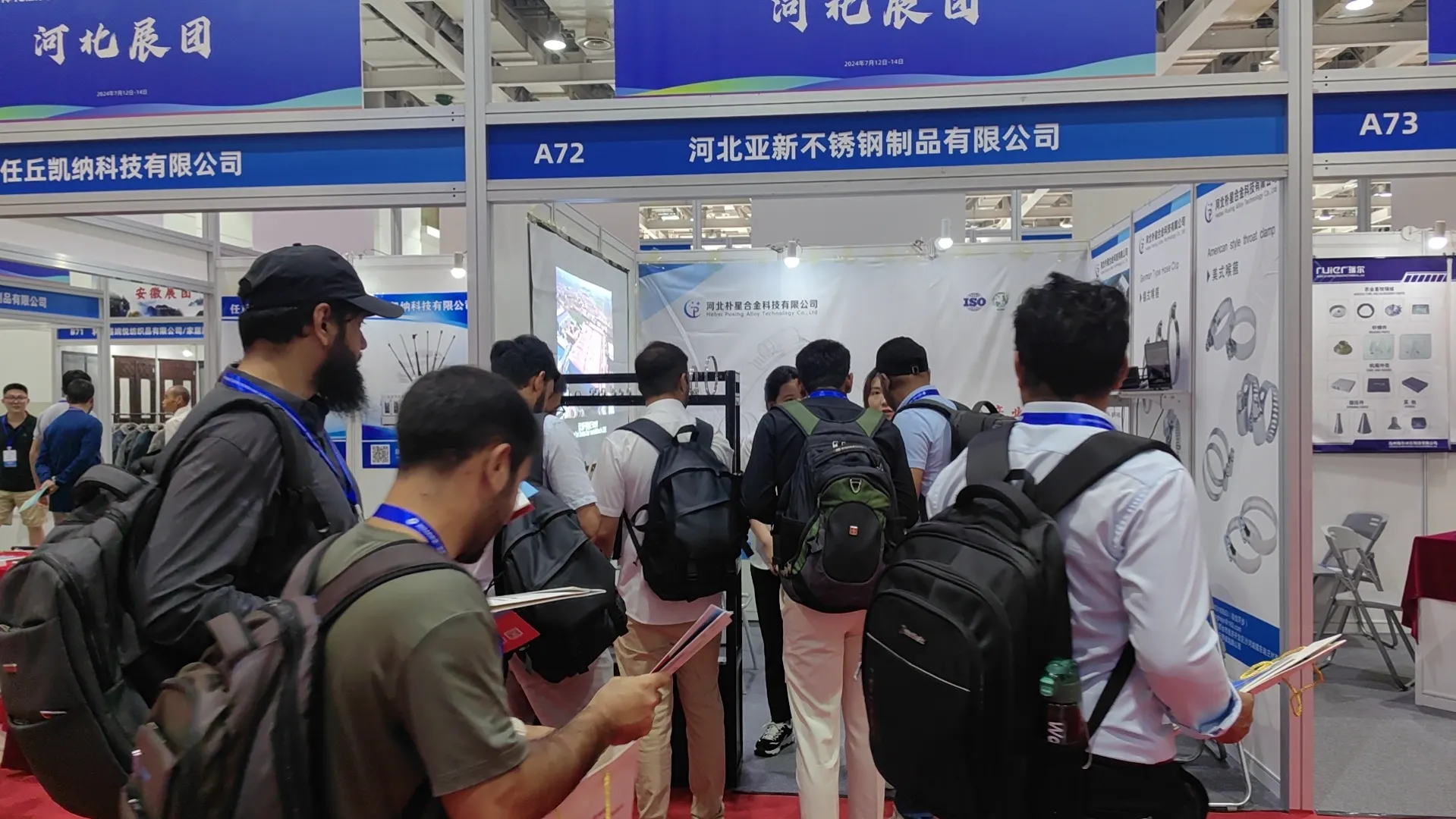

1/4 hose clamps factories

4. Assembly After coating, the clamps are assembled. This can include the attachment of screws or other locking mechanisms to ensure that each clamp can be securely fastened.

5. Quality Control Before the clamps are packaged and shipped, they undergo rigorous quality checks. Factories implement various tests to ensure that the clamps can handle the stresses they will encounter in practical applications.

Quality Standards

Quality assurance is paramount in the manufacturing of hose clamps. Many factories adhere to international standards such as ISO (International Organization for Standardization) certifications, which dictate the requirements for a quality management system. Manufacturers must also ensure that their products meet specific industry standards and are compliant with safety regulations. For instance, automotive hose clamps must meet strict guidelines to ensure they can endure high pressure and temperature variations.

Economic Impact

The production of 1/4 hose clamps is not only essential for end-users but also contributes significantly to the economy. Factories that specialize in hose clamp manufacturing create jobs, stimulate local economies, and contribute to international trade. Moreover, the demand for high-quality hose clamps has surged in recent years, driven by the growth of industries such as automotive, agriculture, and construction. This increased demand highlights the importance of reliable supply chains and robust manufacturing facilities that can adapt to the evolving needs of the market.

Conclusion

In conclusion, 1/4 hose clamps are indispensable components in many industries, providing safety and efficiency in various applications. The factories that manufacture these clamps play a vital role, ensuring quality and reliability through meticulous manufacturing processes and stringent quality control measures. As industries continue to grow and innovate, the demand for high-quality hose clamps will undoubtedly rise, further emphasizing the importance of these manufacturing facilities in both local and global economies. Understanding the significance of hose clamp factories helps us appreciate the intricate systems that keep our machines and infrastructure running smoothly.

-

Large Stainless Steel Adjustable Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | Corrosion Resistance, High Torque

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd.

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsAug.09,2025

-

Premium Steel Insoles: Puncture-Resistant Foot Protection

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.09,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.08,2025