- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Nov . 11, 2024 00:13 Back to list

120mm Hose Clamp Manufacturer Providing High-Quality Solutions for Your Needs

The Importance of Quality in 120mm Hose Clamp Manufacturing

When it comes to ensuring the integrity and longevity of various piping systems, the significance of high-quality hose clamps cannot be overstated. Among the myriad options available in the market, the 120mm hose clamp stands out due to its versatile applications across a range of industries. From automotive to construction, these clamps provide reliable fastening solutions that are crucial for maintaining fluid and gas integrity in hoses.

Overview of Hose Clamps

Hose clamps are mechanical devices used to secure hoses onto fittings. They are essential for preventing leakage and maintaining the precision of installations. Typically, hose clamps come in various sizes and materials; however, the 120mm variant is particularly favored due to its adaptability. Whether made of stainless steel, galvanized steel, or plastic, the choice of material plays a pivotal role in the clamp’s performance and durability.

Manufacturing Process

The production of a 120mm hose clamp involves several key steps, ensuring that each unit meets established quality standards. Firstly, the raw materials are sourced, emphasizing the importance of selecting high-grade metals that exhibit resistance to corrosion and wear. A factory specializing in hose clamp manufacturing often utilizes advanced machinery to cut, shape, and manipulate the metal into the desired form.

Once the components are shaped, they undergo a thorough quality inspection to check for any defects or inaccuracies. This quality assurance step is crucial, as even minor defects in a clamp can lead to significant functional failures in the application. After passing inspections, the clamps are coated or treated to enhance their resistance to various environmental factors, ensuring their suitability for both industrial and household applications.

Importance of Quality Control

Quality control is at the heart of any successful hose clamp factory. Adhering to international standards such as ISO ensures that the products are consistent and reliable. In the competitive market of hose clamps, a reputation for quality can distinguish a factory from its competitors. Manufacturers must not only focus on producing functional clamps but also on minimizing defects and maintaining a robust supply chain.

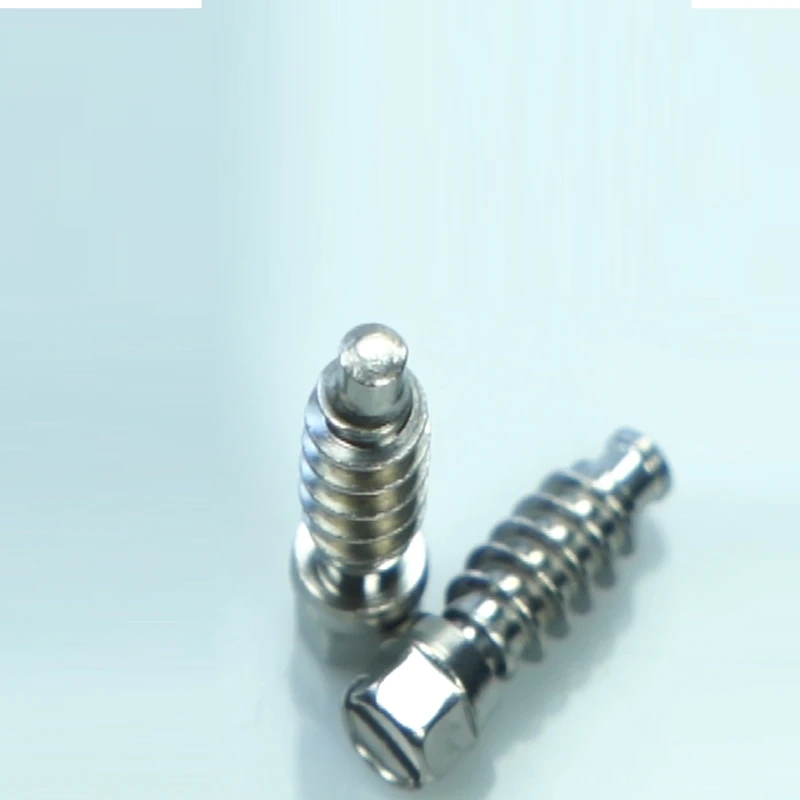

120mm hose clamp factory

Additionally, feedback from clients plays a vital role in the continuous improvement of products. Manufacturers often engage with customers to understand their needs and incorporate their suggestions to enhance product quality. This cycle of feedback and innovation is critical, as it ensures that the hose clamps not only meet but exceed industry expectations.

Applications of 120mm Hose Clamps

The versatility of 120mm hose clamps allows them to be used in various applications. In automotive contexts, they are frequently employed to secure hoses in engines, ensuring that coolant systems operate efficiently without leaks. In the agricultural sector, these clamps are essential for securing irrigation hoses, preventing water loss, and ensuring systems function optimally. Furthermore, in industrial settings, the reliability of a 120mm hose clamp can mean the difference between operational efficiency and costly downtime.

The Future of Hose Clamp Manufacturing

As technology evolves, so do the manufacturing processes for hose clamps. The advent of smart manufacturing, where IoT (Internet of Things) technologies are integrated into production lines, promises enhanced efficiency and precision. Factories that invest in automation and data analytics can significantly reduce production times while increasing the quality of their products.

Sustainability is also becoming a crucial factor in hose clamp manufacturing. Consumers are increasingly seeking products that are eco-friendly, prompting factories to adopt sustainable practices in their sourcing and manufacturing processes. Utilizing recyclable materials and reducing waste are steps many manufacturers are now taking to align with global sustainability goals.

Conclusion

The 120mm hose clamp factory is not just a producer of fastening devices; it is a cornerstone of numerous industries that rely on the secure and efficient functioning of piping systems. By emphasizing quality, embracing technological advancements, and committing to sustainability, these factories can thrive in an ever-evolving market. As consumers become more discerning, the demand for high-quality hose clamps will only continue to grow, making the role of manufacturers more critical than ever.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&High Breaking Torque

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance&Industrial Applications

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp-Hebei Pux Alloy Technology Co., Ltd|Corrosion Resistance, Adjustable Design

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd. | High Breaking Torque & Corrosion Resistance

NewsJul.30,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsJul.30,2025