- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

Jul . 22, 2025 00:01 Back to list

High Quality Steel Midsoles in EN Standard | Safety Footwear

Discover how industry-leading stainless steel midsoles enhance puncture protection while meeting EN standard requirements

Hebei Pux Alloy Technology Co., Ltd - Your Trusted Safety Partner

As a certified manufacturer of premium stainless steel midsoles, we combine cutting-edge technology with strict quality control to deliver unmatched protective solutions.

Contact Details:

Phone: +86-0319-8862898

Mobile: +86-17331948172

Email: inquiry@puxingclamp.com

Manufacturing Facility:

East Zhaozhuang Village, Shahe Town

Xingtai City, Hebei Province, China

Innovations in Steel Midsole Technology

The global safety footwear market continues to evolve with increased emphasis on worker protection. According to recent industrial safety reports, foot injuries account for approximately 7% of all workplace injuries annually. Premium steel midsoles have become essential safety components, providing critical protection against sharp objects penetrating the sole.

The Pux Alloy Advantage

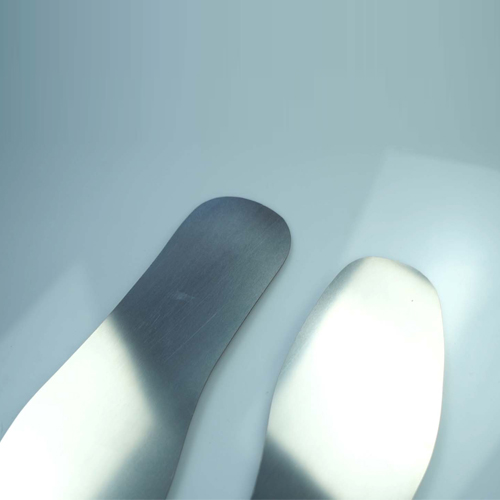

Our High Quality EN Standard Stainless Steel Midsole represents the pinnacle of protective technology. Made from premium stainless steel, our midsoles deliver exceptional puncture resistance while exceeding international safety standards. The advanced epoxy resin matte powder spray coating enhances adhesion and provides superior rust protection.

Technical Specifications of Premium Steel Midsoles

Engineered to perfection, our stainless steel midsoles are designed to provide the ultimate balance of protection, durability, and comfort. The precise technical specifications ensure compliance with the most stringent safety requirements.

| Parameter | Standard Specification | Pux Alloy Premium Grade | Industry Average |

|---|---|---|---|

| Material Composition | AISI 410 Stainless Steel | AISI 420 High-Carbon Stainless | AISI 304 Stainless |

| Thickness | 0.48mm min (EN 12568) | 0.49mm ± 0.01mm | 0.48mm |

| Penetration Resistance | 1100N (EN 12568) | 1200N ± 20N | 1100N |

| Flex Resistance | 1,000,000 cycles (EN) | 1,100,000 cycles (min) | 1,000,000 cycles |

| Surface Treatment | Standard Powder Coating | Epoxy Resin Matte Powder Spray | Basic Powder Coating |

| Corrosion Resistance | 72h salt spray test | 100h salt spray resistance | 72h protection |

| Weight | ≤150g (Size 42) | 135g (Size 42) | 145g |

Performance Analysis of Steel Midsoles

Industry-Leading Manufacturing Standards

At our EN-certified facilities, we implement rigorous quality control throughout the steel midsole production process. From material selection to final inspection, every step is monitored according to ISO 9001 and EN 12568 compliance requirements.

Application Scenarios

The Pux Alloy steel stainless midsole for safety shoes is engineered for diverse environments:

- Construction Sites: Protection against sharp debris and nails

- Manufacturing Facilities: Guarding against metal shavings

- Mining Operations: Defense against rock penetration

- Logistics & Warehousing: Protection from dropped sharp objects

- Oil & Gas Industry: Combustible environment safety

Ready to Enhance Your Safety Footwear?

Experience the superior protection of certified stainless steel midsoles manufactured to exacting standards

Request Technical SpecificationsTechnical FAQ: Steel Midsoles

Q: What distinguishes stainless steel midsoles from other anti-penetration materials?

A: Premium stainless steel midsoles offer superior strength-to-weight ratio compared to composite alternatives. With a minimum 1200N penetration resistance and endurance beyond 1,100,000 flex cycles, stainless steel provides optimal protection against sharp hazards while maintaining flexibility. The molecular structure of high-carbon stainless steel resists permanent deformation under impact loads.

Q: How do EN 12568 and CSA standards differ for steel midsoles?

A: EN 12568 requires a minimum penetration resistance of 1100N and flex endurance of 1 million cycles. CSA Z195-02 requires slightly higher impact protection levels at 1200N with 1.5 million flex cycles. Our stainless steel midsoles exceed both standards with 1200N penetration resistance and 1.1 million verified flex cycles.

Q: What thickness provides optimal protection in steel midsoles?

A: Industry testing shows that 0.49mm stainless steel offers the ideal balance between protection and flexibility. Thinner materials compromise penetration resistance while thicker plates increase fatigue and reduce comfort. Our precision-engineered 0.49mm thickness maintains compliance while enhancing durability.

Q: How does epoxy resin coating enhance steel midsole performance?

A: Our specialized matte powder spray coating provides three critical benefits: (1) Enhanced adhesion with shoe components during manufacturing, (2) Superior corrosion resistance exceeding salt spray test requirements, (3) Reduced friction between layers during flex cycles, extending the functional lifespan of the safety footwear.

Q: What stainless steel grades are suitable for midsoles?

A: Grade 420 stainless steel (1.4021) is ideal for steel plate midsoles due to its high carbon content (0.15% min) and chromium content (12-14%). This combination provides the necessary hardness for penetration resistance while maintaining sufficient ductility to withstand repeated flex cycles without fracturing. Lower grades like 304 stainless lack adequate hardness for maximum protection.

Q: How should manufacturers integrate steel midsoles into safety shoes?

A: The integration process requires precision: (1) The midsole must be positioned between the outsole and insole, (2) Proper bonding adhesives must be applied under controlled temperature (150-170°C), (3) A minimum 24-hour curing period ensures adhesion integrity, (4) Perimeter stitching enhances structural integrity in high-stress areas.

Q: What quality control measures are implemented during production?

A: At our EN-certified facilities, we conduct: (1) Raw material spectrometry analysis, (2) Thickness measurements at 6 points per plate, (3) Automated visual inspection for micro-cracks, (4) Statistical process control of stamping parameters, (5) Batch testing for penetration and flex resistance, (6) Salt spray corrosion validation.

Industry Recognition

"The evolution of steel midsoles has significantly reduced occupational foot injuries in high-risk industries. Modern stainless steel designs provide protection levels that were unachievable a decade ago."

- European Safety Footwear Association Technical Review, 2022

Reference: https://www.esfa.org/technical-reviews/safety-components-2022

"Testing demonstrates that advanced stainless steel midsoles meeting EN 12568 standards maintain protective integrity after simulated five-year usage cycles under industrial conditions."

- Journal of Occupational Health & Safety, Volume 47(3)

This is the last article

-

High Quality Steel Midsoles in EN Standard | Safety Footwear

NewsJul.22,2025

-

Premium Cold Rolled Stainless Steel Strips | High Precision & Smooth

NewsJul.21,2025

-

High Quality T Bolt Hose Clip Factory & Suppliers Durable Stainless Steel Hose Clamps for Industrial Use

NewsJul.08,2025

-

High-Quality Hose Clamp & T Clamp Hose Clamp Reliable Factory & Suppliers

NewsJul.08,2025

-

Cold Rolled Stainless Steel Band - Premium Quality Supplier & Factory Price

NewsJul.08,2025

-

High-Quality Steel Strip from China Stainless Steel Coil & Cold Rolled Carbon Strip Manufacturer & Supplier

NewsJul.07,2025