products

A screw hose clamp, commonly called a worm-drive clamp, is a versatile and adjustable fastening device used to secure hoses onto fittings. It consists of three main components: a perforated stainless steel band, a threaded screw mechanism, and a slotted screw head.

The clamp works by tightening the screw, which pulls the band uniformly around the hose, creating a secure, leak-proof seal. Its adjustable design accommodates various hose diameters, while the stainless steel construction ensures durability and corrosion resistance in demanding environments.

Widely used in automotive, plumbing, and industrial applications, screw hose clamps offer easy installation, reusability, and reliable performance. They are ideal for coolant systems, fuel lines, and hydraulic connections, providing strong clamping force without damaging the hose when properly installed.

-

Genera caligarum fibulae ANISOCYCLUM

Verbum immaculatam ferro ANISOCYCLUM Cochleas ferreas typice significat cum facultate resistendi corrosioni ex aere, aqua, acida, alcali, sale, vel aliis mediis mordax. Cochleae chalybeae immaculatae plerumque corrosio-repugnantiae, durabiles sunt, et applicationes in apparatu tutelae environmental, machinae medicae, instrumento communicationis, et in aliis campis, secundum mixturae compositionem, emphasi variari possunt inter proprietates immaculatas et resistentia acidorum. Quidam chalybes, dum corrosio repugnans, non sit necesse esse acido reluctans. Ferri acido-repugnantes typice etiam proprietates immaculatas possident. In cotidiana vita hominum, vulgo ad chalybem immaculatum, saepe austeniticum immaculatum chalybeum refertur. Clavitores immaculati in primis gradibus austeniticis utimur sicut 302, 304, 316, et 201 "low-nickel", secundum exigentias specificas.

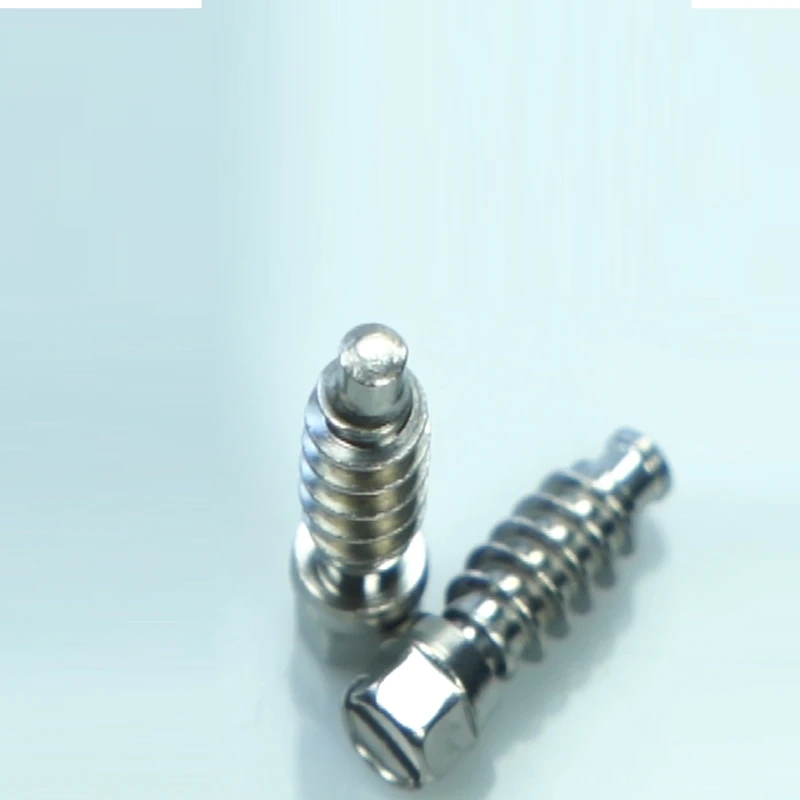

Product nomen:screw ad caligarum Fibulae

figura capitis; Hexagon caput ANISOCYCLUM

Signa correspondentia: ISO, BS,ANSI,GB,DIN,JIS,non-standard

Specificationis exemplar: M6\M8

Materia: 201, 304, 22A .

Calor treatment: Carburizing ac nickel plating in ferro

Modus stipare: Lorem exempla secundum.

How to Use a Screw Hose Clamp?

Select the Right Size: Choose a clamp slightly smaller than the hose diameter when fully open to ensure a tight fit.

Position the Clamp: Slide the clamp over the hose end before attaching it to the fitting. Ensure the screw head faces outward for easy access.

Connect the Hose: Push the hose firmly onto the pipe or barbed fitting until it seats completely.

Tighten the Clamp: Center the clamp over the connection, then use a screwdriver to turn the screw clockwise. Tighten until the hose is snug but avoid over-tightening, which can damage the hose.

Check for Leaks: Test the system under pressure and adjust if necessary.

Characteristics of Screw Hose Clamps

Screw hose clamps, also known as worm-drive clamps, feature a stainless steel band with evenly spaced grooves and a threaded screw mechanism for adjustable tightening. Their key advantage is 360-degree uniform pressure distribution, ensuring leak-proof seals on hoses of various diameters.

The corrosion-resistant stainless steel construction makes them durable in wet, high-temperature, or chemical-exposed environments. The slotted screw head allows easy adjustment with standard screwdrivers, offering convenient installation and maintenance. Unlike fixed clamps, their adjustable tension accommodates hose compression over time.

These clamps provide strong clamping force while preventing hose damage when properly tightened. Their simple, reusable design works across automotive, industrial, and household applications, balancing reliability with cost-effectiveness.