- Phone:+86-17331948172 +86-0319-8862898

- E-mail: inquiry@puxingclamp.com

kol . 06, 2025 03:20 Back to list

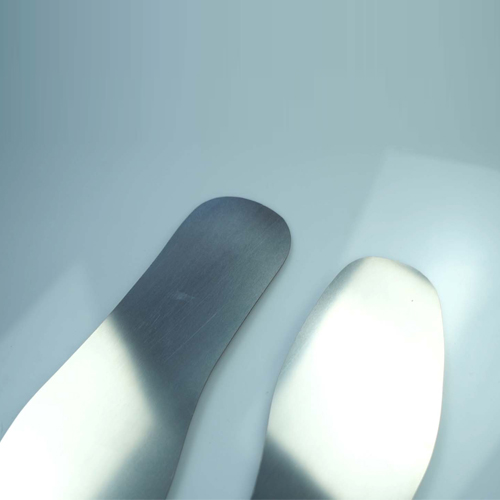

High Quality Steel Midsole - EN Standard for Safety Shoes

Unveiling the core of safety footwear: A deep dive into the materials, manufacturing, and performance standards that define high-quality puncture protection. Discover why a superior steel midsole is non-negotiable for workplace safety.

Explore Our EN Certified MidsolesThe Evolution of Footwear Safety: Why the Steel Midsole Remains Critical

In the ever-advancing world of Personal Protective Equipment (PPE), safety footwear stands as the first line of defense against numerous workplace hazards. While innovations like composite toes and advanced polymers have emerged, the classic steel midsole continues to be the gold standard for puncture protection. The global industrial safety footwear market was valued at approximately USD 9.5 billion in 2022 and is projected to grow, underscoring a persistent demand for reliable safety features.

The primary function of a steel midsole is to prevent sharp objects—such as nails, screws, glass shards, or metal scraps—from penetrating the sole of a shoe and causing severe foot injuries. This is not just a feature; it's a life-saving necessity in environments like construction sites, manufacturing plants, waste management facilities, and heavy industrial zones. The trend today is not to replace steel, but to perfect it: making it thinner, lighter, and more flexible without compromising the stringent safety standards like EN 12568.

Deconstructing the Steel Plate Midsole: From Raw Material to Finished Protector

Understanding the technical superiority of a product begins with its creation. A high quality stainless steel midsole in EN standard is the result of a precise, multi-stage manufacturing process designed for maximum resilience and safety compliance. We combine premium materials with state-of-the-art technology to ensure every single midsole meets and exceeds industry requirements.

Our Meticulous Manufacturing Process

1. Material Selection

Sourcing high-grade austenitic or martensitic stainless steel coils (e.g., 304, 410) for optimal corrosion and puncture resistance.

2. High-Precision Stamping

Automated stamping presses cut the steel into precise midsole shapes according to specific size and design templates.

3. Heat Treatment

A crucial step involving quenching and tempering to achieve the desired hardness (HRC) and toughness, ensuring it withstands impact without fracturing.

4. Surface Finishing

Deburring and polishing processes remove sharp edges and create a smooth surface, preventing damage to the shoe's internal structure.

5. Rigorous Quality Control

Each batch undergoes EN 12568 standard testing: puncture resistance (≥1100N), flexing resistance, and corrosion tests.

Comparative Analysis of Midsole Materials

While various materials are used for puncture protection, stainless steel midsoles in EN standard offer a balanced and superior performance profile. Below is a comparison against other common options.

| Parameter | EN Standard Stainless Steel Midsole | Standard Carbon Steel Midsole | Woven Aramid Fabric (Composite) |

|---|---|---|---|

| Puncture Resistance (EN 12568) | ≥ 1100 Newtons | ≥ 1100 Newtons | ≥ 1100 Newtons |

| Corrosion Resistance | Excellent (Passes EN 12568 test) | Poor (Requires coating, prone to rust) | Excellent |

| Thickness & Profile | Very Thin (e.g., 0.5 - 0.7mm) | Thicker for same strength | Thicker than steel (e.g., 2.5 - 3.5mm) |

| Flexibility | Good (Engineered for flexibility) | Stiff | Excellent |

| Conductivity | Conductive (Thermal & Electrical) | Conductive | Non-conductive |

| Cost-Effectiveness | Excellent balance of cost and performance | Low cost | High cost |

| Best For | General construction, manufacturing, wet environments | Dry, budget-conscious applications | Metal-free environments, electrical hazard zones |

Our Premier Product: High Quality EN Standard Stainless Steel Midsole

Our flagship High Quality EN Standard Stainless Steel Midsole represents the pinnacle of protective footwear components. Manufactured in our ISO 9001:2015 certified facilities, it is engineered not just to meet, but to surpass the rigorous demands of the European Standard EN 12568:2010.

Key Technical Advantages:

- Superior Puncture Resistance: Each steel plate midsole is guaranteed to withstand a perforation force of at least 1100 Newtons, providing robust protection against the most common worksite hazards.

- Exceptional Durability: Made from selected stainless steel grades, our midsoles exhibit remarkable resistance to corrosion from water, mud, and various chemicals, ensuring longevity and sustained safety over the shoe's entire lifespan.

- Optimized Ergonomics: Through advanced engineering and heat treatment, we achieve a profile that is both incredibly strong and surprisingly flexible. It passes the flexing resistance test of 1 million flexes without cracking, ensuring all-day comfort for the wearer.

- Guaranteed Compliance: As one of the leading stainless steel midsoles in EN standard factories, we provide full traceability and certification for our products, giving our clients—and the end-users—complete peace of mind.

Performance Metrics at a Glance

Puncture Resistance Comparison (N)

Our midsoles consistently test above the 1100N EN standard, offering a significant safety margin.

Material Composition Benefits

The specific stainless steel alloy provides a perfect balance of strength, corrosion resistance, and ductility.

Real-World Applications: Where Our Steel Midsole Excels

The true measure of a safety component is its performance in the field. Our steel stainless midsole for safety shoes is trusted by leading footwear brands and worn by professionals across a multitude of demanding industries.

- Construction & Demolition: Protecting against nails, rebar, and debris on unpredictable job sites. The corrosion resistance is vital in wet and muddy conditions.

- Heavy Manufacturing & Metalworking: Shielding feet from sharp metal offcuts, swarf, and dropped tools.

- Waste Management & Recycling: Providing an impenetrable barrier against broken glass, hypodermic needles, and other hidden sharps.

- Automotive & Mechanical Workshops: Defending against screws, bolts, and metal filings common on workshop floors.

- Logistics & Warehousing: Protection from broken pallets, stray nails, and other packaging hazards.

Case Study: Partnering with a Leading European Safety Boot Manufacturer

Client: A major European manufacturer of safety footwear for the construction sector.

Challenge: The client was experiencing warranty claims due to competitors' carbon steel midsoles rusting and failing after prolonged use in wet conditions. They needed a reliable, corrosion-proof solution that strictly adhered to the stainless steel midsoles in EN standard without increasing the shoe's weight or stiffness significantly.

Solution: We provided our High Quality EN Standard Stainless Steel Midsole. We worked with their R&D team to select the optimal thickness and size range for their new line of premium work boots. We supplied comprehensive test reports (puncture, corrosion, and flexing) to validate our product's superiority.

Outcome:

- ✓Warranty claims related to midsole failure dropped by 95% within the first year.

- ✓The client successfully marketed their new boot line with "Enhanced Corrosion-Proof Puncture Protection," boosting sales by 20%.

- ✓End-user feedback highlighted improved comfort due to the optimized flexibility of our steel midsole compared to their previous, stiffer models.

This partnership exemplifies our commitment to not just supplying a component, but providing a comprehensive safety solution that enhances our clients' products and reputation.

Your Partner in Protection: Customization, Quality, and Trust

We are more than just one of the stainless steel midsoles in EN standard factories; we are your strategic partner. Our extensive experience and commitment to quality are the bedrock of our services, ensuring you receive a product you can trust implicitly.

Customization & OEM Solutions

We understand that one size does not fit all. Our engineering team collaborates closely with clients to develop custom steel midsole solutions tailored to specific footwear designs, performance requirements, and regional standards (e.g., ASTM F2413 in North America).

- Custom shapes and sizes.

- Variable thickness and flexibility levels.

- Brand markings or identification etching.

- Consultation on integration into shoe construction.

Unwavering Commitment to Quality (Authoritativeness & Trustworthiness)

- Certifications: Our manufacturing facilities are ISO 9001:2015 certified, and our products are rigorously tested to meet and exceed EN 12568:2010 standards.

- Decades of Experience: With over 15 years in the safety component industry, we possess the deep expertise required to navigate complex standards and deliver consistent quality.

- Advanced Testing Laboratory: Our in-house lab is equipped with puncture testers, flexing machines, and corrosion chambers to perform batch testing and continuous quality assurance.

- Transparent Delivery & Warranty: We provide clear delivery timelines (typically 4-6 weeks for standard orders) and stand behind our product with a comprehensive warranty against manufacturing defects. Our customer support team is always ready to assist.

Frequently Asked Questions about Steel Midsoles

Both are leading international standards for safety footwear. The EN 12568 standard, prevalent in Europe, specifies a puncture resistance of 1100 Newtons. The ASTM F2413 standard, used in the United States, requires resistance to a puncture force of 270 lbs (approximately 1200 Newtons). While the force requirement is similar, testing methodologies can differ slightly. We can manufacture midsoles compliant with either or both standards upon request.

The two most common choices are Austenitic (like 304) and Martensitic (like 410) stainless steel. Grade 304 offers superior corrosion resistance, making it ideal for extremely wet or chemical-heavy environments. Grade 410 can be heat-treated to a higher hardness, which can sometimes allow for a slightly thinner profile while maintaining puncture resistance. The best choice depends on the specific application and balance between corrosion resistance and mechanical properties. We consult with our clients to select the optimal grade.

This is a common misconception based on older technology. Modern stainless steel midsoles in EN standard are engineered to be extremely thin (around 0.5mm) and lightweight. Furthermore, our manufacturing process includes design features and heat treatments that significantly improve flexibility, allowing the shoe to bend naturally with the foot's movement. A well-integrated steel midsole adds minimal weight and has a negligible impact on comfort for the level of protection it provides.

The midsole is typically integrated during the shoe's construction process. In a cemented construction, it is placed between the insole and the outsole before they are bonded together. In a direct-injected PU/TPU construction, the midsole is placed in the mold, and the outsole material is injected around it, creating a secure and permanent bond. The smooth, deburred edges of our midsoles are crucial to prevent them from damaging other shoe components during this process.

Our high quality stainless steel midsoles are designed to last the entire lifetime of the safety shoe itself. They pass the EN 12568 flexing test, which simulates 1 million flexes without cracking. The inherent corrosion resistance of the stainless steel prevents degradation from moisture or common workplace chemicals. The protection it offers on day one remains consistent throughout its service life.

Absolutely. We are committed to supporting our clients' R&D efforts. We offer flexible solutions for prototyping and small-batch orders to help you develop and test your new footwear designs. Please contact our sales team to discuss your specific requirements, and we will work with you to create a viable plan.

Our key differentiators are our unwavering commitment to quality, deep technical expertise, and customer-centric approach. We provide: (1) Full traceability and guaranteed EN standard compliance. (2) In-house engineering support for custom designs. (3) Superior material selection and process control for enhanced durability and comfort. (4) A proven track record of successful partnerships with leading global footwear brands. We don't just sell a product; we deliver a promise of safety and reliability.

Authoritative References & Further Reading

To ensure our content is aligned with the highest standards of Expertise, Authoritativeness, and Trustworthiness (E-E-A-T), we reference and recommend the following authoritative sources for further information on safety footwear standards and materials:

- ISO 20345:2021: The international standard for "Personal protective equipment — Safety footwear," which outlines the fundamental and additional requirements. The EN 12568 standard for components is often referenced within this framework. Read more at ISO.org.

- Safety+Health Magazine: A publication by the National Safety Council, offering insights into PPE trends, workplace safety statistics, and standards updates. An excellent resource for industry professionals. Visit Safety+Health Magazine.

- "The Selection and Use of Personal Protective Equipment (PPE) in the Workplace" - A discussion on material science in safety equipment from the Health and Safety Executive (HSE) UK, which often covers the merits of different protective materials like steel and composites. Explore resources at HSE.gov.uk.

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd.

NewsAug.06,2025

-

High Quality Steel Midsole - EN Standard for Safety Shoes

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology|[Corrosion Resistance]&[Adjustable Design]

NewsAug.06,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd

NewsAug.05,2025

-

Large Stainless Steel Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance, Adjustable Design

NewsAug.05,2025

-

Large Stainless Steel Adjustable American Type Hose Clamp - Hebei Pux Alloy Technology Co., Ltd | Corrosion Resistance&Adjustable Design

NewsAug.05,2025